Method for preparing plant potassium-containing super absorbent resin by corncob one-pot method

A technology for super absorbent resin and corn cob, which is applied to the field of preparing plant potassium-containing super absorbent resin by a corn cob one-pot method, can solve the problems of increased cost, high reaction temperature, increased consumption of organic solvents, etc., and achieves cost saving and simple synthesis process. , the effect of large market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

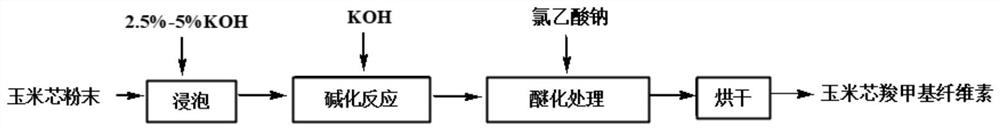

[0072] First, add 5g of potassium hydroxide to 200mL of deionized water to form a potassium hydroxide solution with a mass concentration of 2.5%, cool it for use, then add the above potassium hydroxide solution into a 1000mL beaker, add 30g of it under stirring and grind it through 100 mesh Sieved corncob powder, soaked for 5h. In a water bath at 30°C, add 20mL of sodium hydroxide solution with a mass fraction of 20% dropwise under the condition of large stirring, and maintain the alkalinization reaction at 30°C for 90min; dissolve 10.71g of sodium chloroacetate in 35.7mL of deionized water, Prepare a sodium chloroacetate etherification agent solution with a mass fraction of 30%. When the temperature rises to 75°C, slowly add the above sodium chloroacetate etherification agent solution dropwise to the alkalized corncob fiber soaking solution under stirring conditions During the etherification reaction for 120 minutes; the above product was taken out, dried in an oven at 70°C, ...

Embodiment 2

[0076] First, add 6g of potassium hydroxide to 200mL of deionized water to form a potassium hydroxide solution with a mass concentration of 3%, cool it for use, then add the above-mentioned potassium hydroxide solution into a 1000mL beaker, add 30g of it before stirring and grind it through 100 mesh Sieved corn cob powder, soaked for 3.5h. In a water bath at 30°C, add 25mL of potassium hydroxide solution with a mass fraction of 20% dropwise under the condition of large stirring, and maintain the alkalinization reaction at 30°C for 90min; dissolve 11.75g of sodium chloroacetate in 39mL of deionized water, and prepare Prepare a 30% sodium chloroacetate etherification agent solution, and when the temperature rises to 75°C, slowly add the above sodium chloroacetate etherification agent solution dropwise to the alkalized corncob fiber soaking solution under stirring conditions , etherification reaction for 105min; take out the above product, dry it in an oven at 70°C, take it out...

Embodiment 3

[0080] First, add 6g of potassium hydroxide to 200mL of deionized water to make a potassium hydroxide solution with a mass concentration of 3%, cool it for later use, then add the above potassium hydroxide solution into a 1000mL beaker, add 30g of it before stirring and grind it through 100 mesh Sieved corn cob powder, soaked for 3.5h. In a water bath at 30°C, add 25mL of potassium hydroxide solution with a mass fraction of 20% dropwise under the condition of large stirring, and maintain the alkalinization reaction at 30°C for 90min; dissolve 13.49g of sodium chloroacetate in 45mL of deionized water, and prepare Make a 30% sodium chloroacetate etherification agent solution, and when the temperature rises to 75°C, slowly add the above sodium chloroacetate etherification agent solution dropwise to the alkalized corncob fiber soaking solution under stirring conditions , etherification reaction for 105min; take out the above product, dry it in an oven at 70°C, take it out for 48h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com