Air purification equipment for industrial waste gas emission

A technology for air purification equipment and industrial waste gas, which is applied in the direction of chemical instruments and methods, combined devices, and separation of dispersed particles, which can solve the problems of difficult disassembly of filter screens, and achieve the effect of improving operation efficiency, improving treatment effect, and simple disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

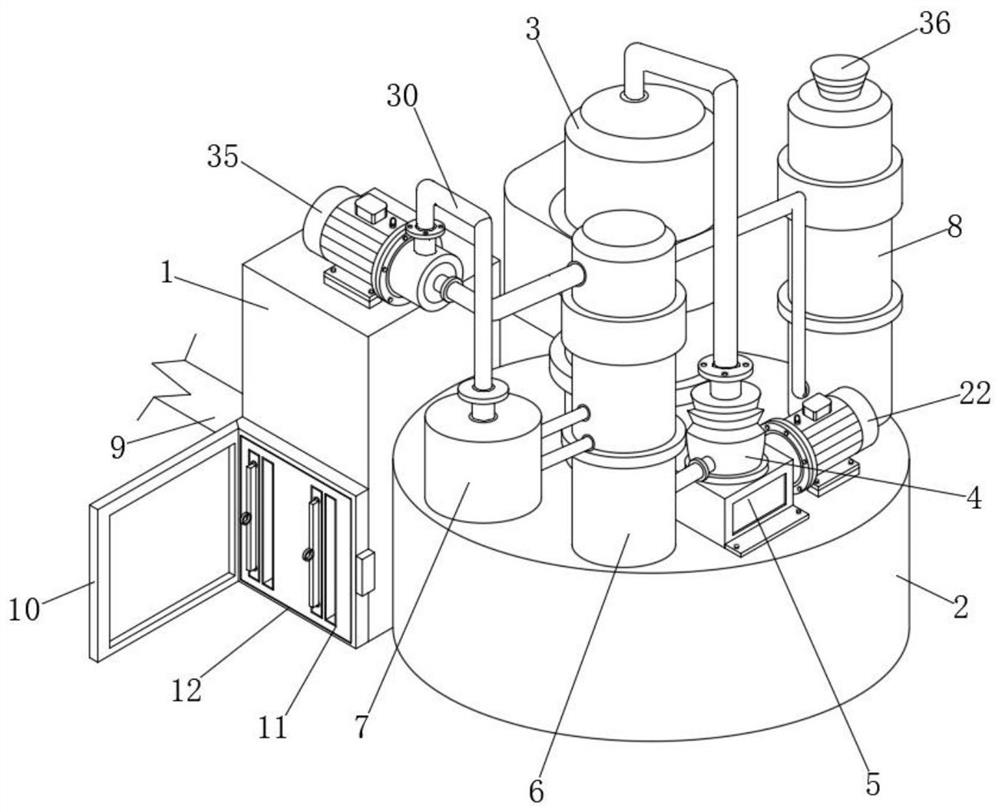

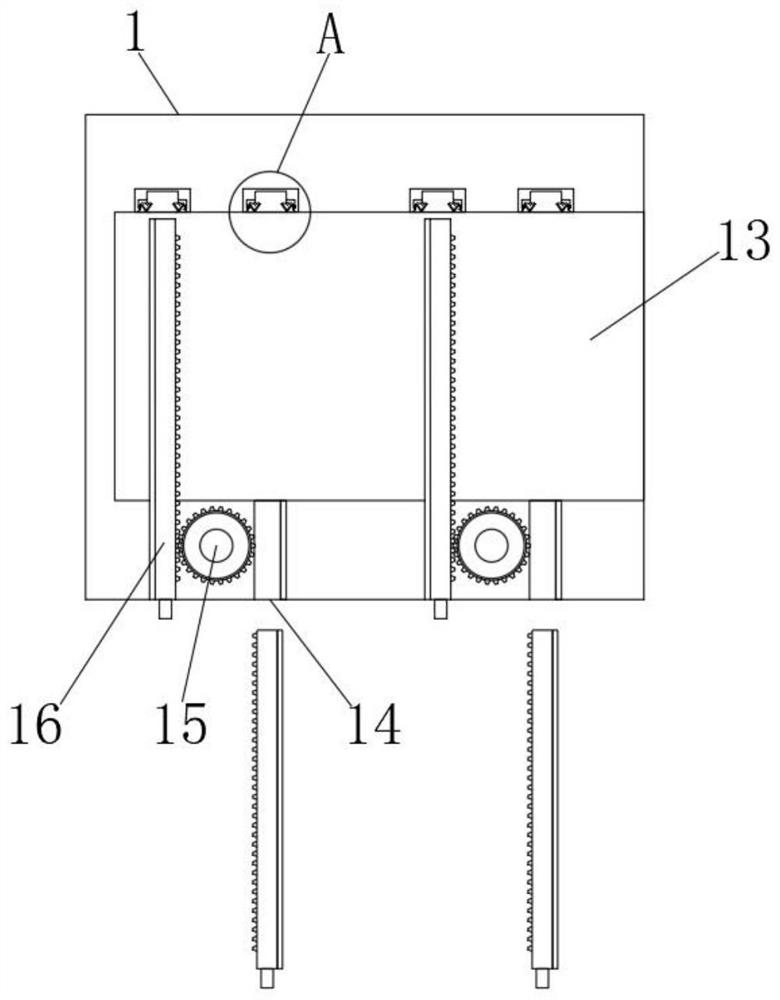

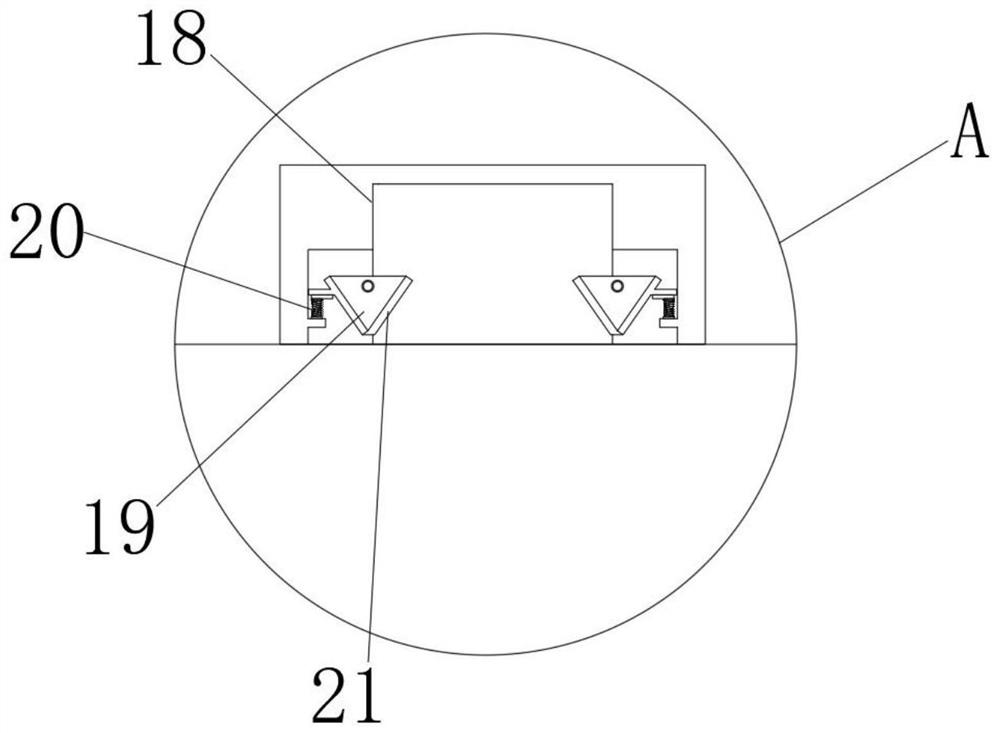

[0034] Such as Figure 1-4As shown, a kind of air purification equipment used for industrial exhaust gas discharge disassembles and replaces the filter plate in the equipment. Open the lock, open the airtight door 10, and at the same time, the staff put on the mask in advance to prevent some exhaust gas from being exposed and affect the staff. The staff prepares the clean intercepting tooth plate 16 in advance, and puts the blocking plate 14 on the interface 11 Immediately insert the new intercepting tooth plate 16 into the interface 11 while taking it off, and when the new intercepting tooth plate 16 enters the interface 11, the gear teeth on the intercepting tooth plate 16 act on the dust removal box 1. Gear 15, causing the old intercepting tooth plate 16 to be unscrewed while the gear 15 is rotating;

[0035] When the front end of the new intercepting tooth plate 16 enters the slot 18 on the filter cavity 13, the exhaust gas inlet pipe 9 is connected to the filter cavity 1...

Embodiment 2

[0037] Such as Figure 5-6 As shown, an air purification device for industrial waste gas discharge performs scrubbing treatment on the waste gas in the device. During specific operation, the large particle impurities in the waste gas are removed by intercepting the filter screen 17 on the intercepting tooth plate 16. At this time, the industrial waste gas is also doped with a large amount of harmful gases soluble in water. By scrubbing the waste gas, the harmful waste gas is dissolved in water, and then the reagent is directly added to the solution, making the treatment of industrial waste gas simpler and safer;

[0038] The filter cavity 13 is connected with the exhaust pipe 27, and the exhaust gas enters the shower box 2 through the air outlet 28 on the exhaust pipe 27. At this time, the staff turns on the water pump 22, and the water pump 22 turns on the temperature at 50-70 degrees Celsius prepared by the staff in advance. The exhaust gas treatment reagent is pressurized a...

Embodiment 3

[0042] Such as Figure 8-10 As shown, a kind of air purification equipment used for industrial waste gas discharge performs circular adsorption treatment on the waste gas. During specific operation, the exhaust pump 35 draws the waste gas in the circulating filter tank 6 from the bottom. At this time, the second electric push rod 38 Start to work, the sealing block 39 on the fixed plate 33 is released, and the front end of the second electric push rod 38 is connected with the connecting rod 322, and the second electric push rod 38 is elongated, driving the connecting rod 322 to elongate, and the elongated connecting rod 322 During the rising process, the limit rod 325 is pushed upward in the limit groove 324, and the connecting rod 322 drives the sealing plate 323 to be pushed out from the vent 326 of the movable plate 321 on the partition mechanism 32, because the rising connecting rod 322 drives the entire movable plate 321 The recirculation filter tank 6 rises in the tank b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com