Flexible lithium/sodium ion battery negative electrode material and preparation method thereof

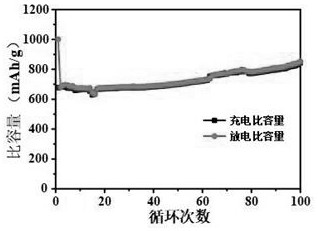

A technology for sodium ion batteries and negative electrode materials, applied in the field of electrochemistry, can solve the problems of poor contact between active materials and current collectors, poor electronic conductivity, and large volume changes, and achieve excellent electrochemical performance, good flexibility, and production technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

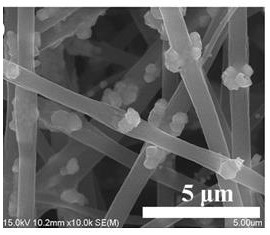

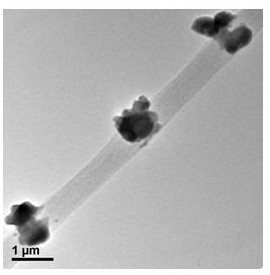

[0025] The preparation method of flexible lithium / sodium ion battery negative electrode material specifically comprises the following steps:

[0026] 1) Stir and disperse 0.01g of zinc acetate, 0.02g of manganese acetate and 0.2g of polyacrylonitrile into 6ml of dimethylformamide solution to form a spinning precursor solution;

[0027] 2) Transfer the obtained precursor solution into a syringe, the advance speed of the syringe pump is 0.01cm / min, the spinning voltage is 13kV, and the distance between the receiving roller and the front end of the syringe is 8cm, and the precursor fiber film is prepared;

[0028] 3) Put the obtained precursor fiber film into a tube furnace for pre-oxidation, the temperature is set to 200°C, the heating rate is 1°C / min, the pre-oxidation time is 1h, and the nitrogen atmosphere is used to obtain the pre-oxidized precursor fiber film ;

[0029] 4) Put the obtained pre-oxidized precursor fiber film into a tube furnace for high-temperature carboniza...

Embodiment 2

[0031] 1) Stir and disperse 0.02g of zinc acetate, 0.04g of manganese acetate and 0.3g of polyacrylonitrile into 6ml of dimethylformamide solution to form a spinning precursor solution;

[0032] 2) Transfer the obtained precursor solution into a syringe, the advance speed of the syringe pump is 0.02cm / min, the spinning voltage is 13.5kV, and the distance between the receiving roller and the front end of the syringe is 8.5cm, and the precursor fiber film is prepared;

[0033] 3) Put the obtained precursor fiber film into a tube furnace for pre-oxidation. The temperature is set at 210°C, the heating and cooling rates are both 1°C / min, the pre-oxidation time is 1h, and the nitrogen atmosphere is used to obtain the pre-oxidized precursor body fibrous membrane;

[0034] 4) Put the obtained pre-oxidized precursor fiber film into a tube furnace for high-temperature carbonization. The temperature is set at 750 °C, the heating and cooling rates are both 1 °C / min, the carbonization time...

Embodiment 3

[0036] 1) Stir and disperse 0.05g of zinc acetate, 0.1g of manganese acetate and 0.6g of polyacrylonitrile into 6ml of dimethylformamide solution to form a spinning precursor solution;

[0037] 2) Transfer the obtained precursor solution into a syringe, the advance speed of the syringe pump is 0.05cm / min, the spinning voltage is 14 kV, and the distance between the receiving roller and the front end of the syringe is 8.5cm, and the precursor fiber membrane is prepared;

[0038] 3) Put the obtained precursor fiber film into a tube furnace for pre-oxidation. The temperature is set to 220°C, the heating and cooling rates are both 1°C / min, the pre-oxidation time is 1h, and the nitrogen atmosphere is used to obtain the pre-oxidized precursor body fibrous membrane;

[0039] 4) Put the obtained pre-oxidized precursor fiber film into a tube furnace for high-temperature carbonization. The temperature is set to 750°C, the heating and cooling rates are both 1°C / min, the carbonization time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com