Separation method of palmitoyl pentapeptide-4

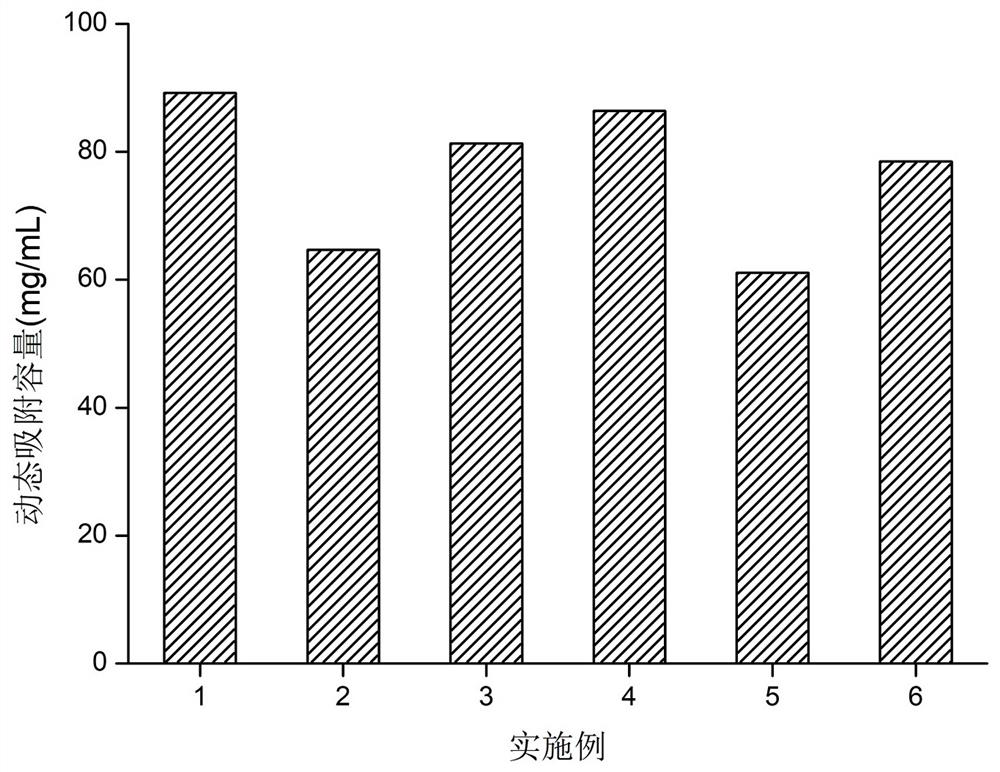

A technology of palmitoyl pentapeptide and glucan gel, which is applied to the preparation methods of peptides, chemical instruments and methods, peptides, etc., can solve the problems of large consumption of organic solvents, cumbersome steps, low efficiency, etc. The effect of high adsorption capacity and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This embodiment provides a method for preparing modified dextran gel microspheres, the method comprising the following steps:

[0073] 1) Dissolve dextran with a molecular weight of 40,000 g / mol in deionized water and stir evenly according to the ratio of material to liquid 1g:8mL, add sodium periodate with 0.45 times the mass of dextran in an ice-water bath, and react in the dark at room temperature for 3.5 h, dialyzed, and freeze-dried to obtain aldylated dextran;

[0074] 2) Mix the formylated dextran obtained in step 1), sodium chloride, and deionized water according to the mass ratio of 1:0.26:3.8, stir evenly at room temperature, and add o-sulfonic acid 0.32 times the mass of the formylated dextran p-Phenylenediamine, stirred for 8 minutes, stirred at 65°C for 25 minutes to obtain dextran gel;

[0075] 3) Mix Sephadex and 20wt% isopropanol aqueous solution at a mass ratio of 1:3, stir and swell for 40 minutes, add 2-(3-methoxyphenyl)isonicotinic acid 3.2 times th...

Embodiment 2

[0078] This example provides another preparation method of modified dextran gel microspheres, the steps are basically the same as in Example 1, the difference is that in step 3) 2-(3-methoxyphenyl) The amount of isonicotinic acid added is 1.5 times the mass of Sephadex.

Embodiment 3

[0080] This example provides another preparation method of modified dextran gel microspheres, the steps are basically the same as in Example 1, the difference is that in step 3) 2-(3-methoxyphenyl) The amount of isonicotinic acid added is twice the mass of Sephadex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com