Indicator material as well as preparation method and application thereof

An indicator and raw material technology, applied in the field of indicator materials and their preparation, can solve the problems of low reaction sensitivity and poor safety, and achieve the effects of simple preparation process, sunburn prevention, and fast response speed of discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention provides a preparation method for the indicator material described in the above technical solution, comprising the following steps:

[0064] The organosilicon monomer, the hydrophilic monomer, the photochromic monomer, the crosslinking agent, the initiator, the free radical scavenger and the UV absorber are mixed and polymerized to obtain the indicator material.

[0065] The present invention has no special limitation on the mixing process of the organosilicon monomer, hydrophilic monomer, photochromic monomer, crosslinking agent, initiator, free radical scavenger and UV absorber, according to well-known methods in the art The process is to mix the materials evenly. In the present invention, the polymerization temperature is preferably ≥80°C, more preferably 80-100°C, most preferably 100°C; the polymerization time is preferably 1-14h, more preferably 12h.

[0066] In the present invention, in order to shape the indicator material, the polymerizati...

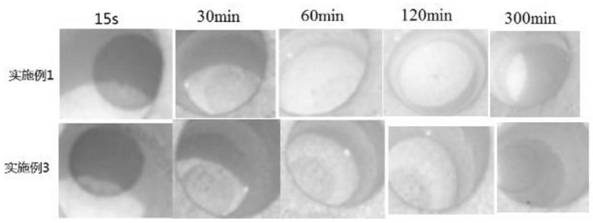

Embodiment 1

[0075] Add 50 parts of 3-(3-methacryloyloxy-2-hydroxypropyl)propylbis(trimethylsiloxane)methylsilane and HEMA (hydroxyethyl methacrylate) successively into a glass beaker 35 parts, 15 parts of NVP (N-vinylpyrrolidone), 0.5 parts of ethylene glycol dimethacrylate (crosslinking agent), 0.3 parts of azobisisobutylcyanide and 1 part of spirooxazine, mix well and inject into In a polypropylene mold, polymerize at 100°C for 12 hours; after natural cooling to room temperature, demould, soak in pure water for 12 hours to obtain the indicator material.

Embodiment 2

[0077] Add 50 parts of 3-(3-methacryloyloxy-2-hydroxypropyl)propylbis(trimethylsiloxane)methylsilane, 35 parts of HEMA, 15 parts of NVP, 0.5 Parts of ethylene glycol dimethacrylate, 0.3 parts of azobisisobutyrocyanide, 1 part of spirooxazine and 2 parts of methacrylate-1,2,2,6,6-pentamethyl-4-piperidinate After mixing evenly, pour it into a polypropylene mold, polymerize at 100°C for 12 hours; let it cool down to room temperature, demould it, soak it in pure water for 12 hours, and obtain the indicator material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com