Preparation method of active carbon for supercapacitor

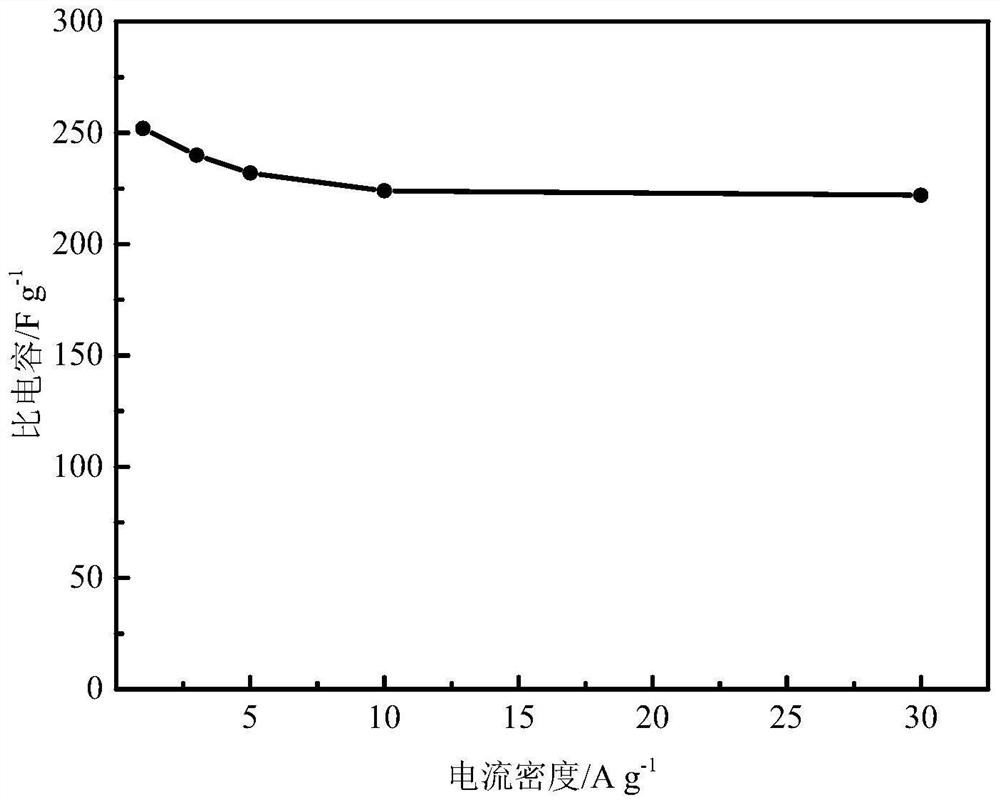

A technology of supercapacitor and activated carbon, which is applied in the manufacture of hybrid/electric double layer capacitors, chemical instruments and methods, hybrid capacitor electrodes, etc. Effects of specific capacitance and energy density, improved wettability and conductivity, excellent specific capacitance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The first aspect of the present disclosure provides a method for preparing activated carbon for supercapacitors, which includes the following steps: after doping brown algae with water-soluble salts, performing a hydrothermal reaction with chitosan, followed by carbonization and activation to prepare supercapacitors Activated carbon.

[0027] In a typical embodiment, the water-soluble salt is a water-soluble calcium salt, further, the water-soluble calcium salt is one or more of calcium chloride, calcium lactate, calcium acetate, calcium gluconate, and calcium sulfate species; further, the concentration of the calcium salt is 0.2-0.6moL / L, preferably 0.4moL / L.

[0028] Utilizing the characteristics of alginic acid and sodium alginate contained in the raw material of brown algae (mainly in the cell wall), the brown algae is doped with water-soluble salt, and the doped calcium ions can effectively replace the sodium ions in the sodium alginate, thereby forming a rich Cal...

Embodiment 1

[0042] (1) Grind fresh Sargassum into granules and put them into a rubber mill, add 0.4moL / L calcium chloride solution to carry out ultrafine pulverization of wet materials for 30 minutes;

[0043] (2) Put the ultrafine pulverized Sargassum wet material into a blast drying oven at 120° C. to dry for 24 hours, then add 4 moL / L hydrochloric acid solution, and carry out pickling treatment in a water bath at a pickling temperature of 60° C. Pickling time 4h;

[0044] (3) Wash the pickled sargassum with deionized water to neutrality, according to the mass ratio of sargassum (3g): chitosan is 1:1, add chitosan and 40mL deionized water in the reaction kettle Hydrothermal treatment, hydrothermal treatment temperature 200°C, hydrothermal treatment time 12h, after cooling to room temperature, take out, filter and wash, then put in 120°C blast drying oven to dry for 12h;

[0045] (4) Put the dried mixed material into a tube furnace and carry out high-temperature carbonization in nitroge...

Embodiment 2

[0053] (1) Grind the fresh kelp into particles and put it into a rubber mill, add 0.2moL / L calcium lactate solution to carry out ultrafine pulverization of wet materials for 25 minutes;

[0054] (2) Put the ultra-finely pulverized kelp wet material into a blast drying oven at 130°C to dry for 22 hours, then add 3moL / L hydrochloric acid solution, and carry out pickling treatment in a water bath. The pickling temperature is 70°C. Washing time 3h;

[0055] (3) Wash the kelp after pickling treatment to neutrality with deionized water. According to the mass ratio of kelp (3g): chitosan is 1:1, add chitosan and 40mL deionized water to carry out hydrothermal treatment in the reactor , the hydrothermal treatment temperature is 220°C, the hydrothermal treatment time is 10h, after cooling to room temperature, it is taken out, filtered and washed, and then put into a blast drying oven at 120°C for 12h;

[0056] (4) Put the dried mixed material into a tube furnace, and carry out high-tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com