A kind of preparation method of ternary metal oxide nanostructure supercapacitor electrode

A supercapacitor, nanostructured technology, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, etc., to achieve the effects of high yield, increased surface area, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

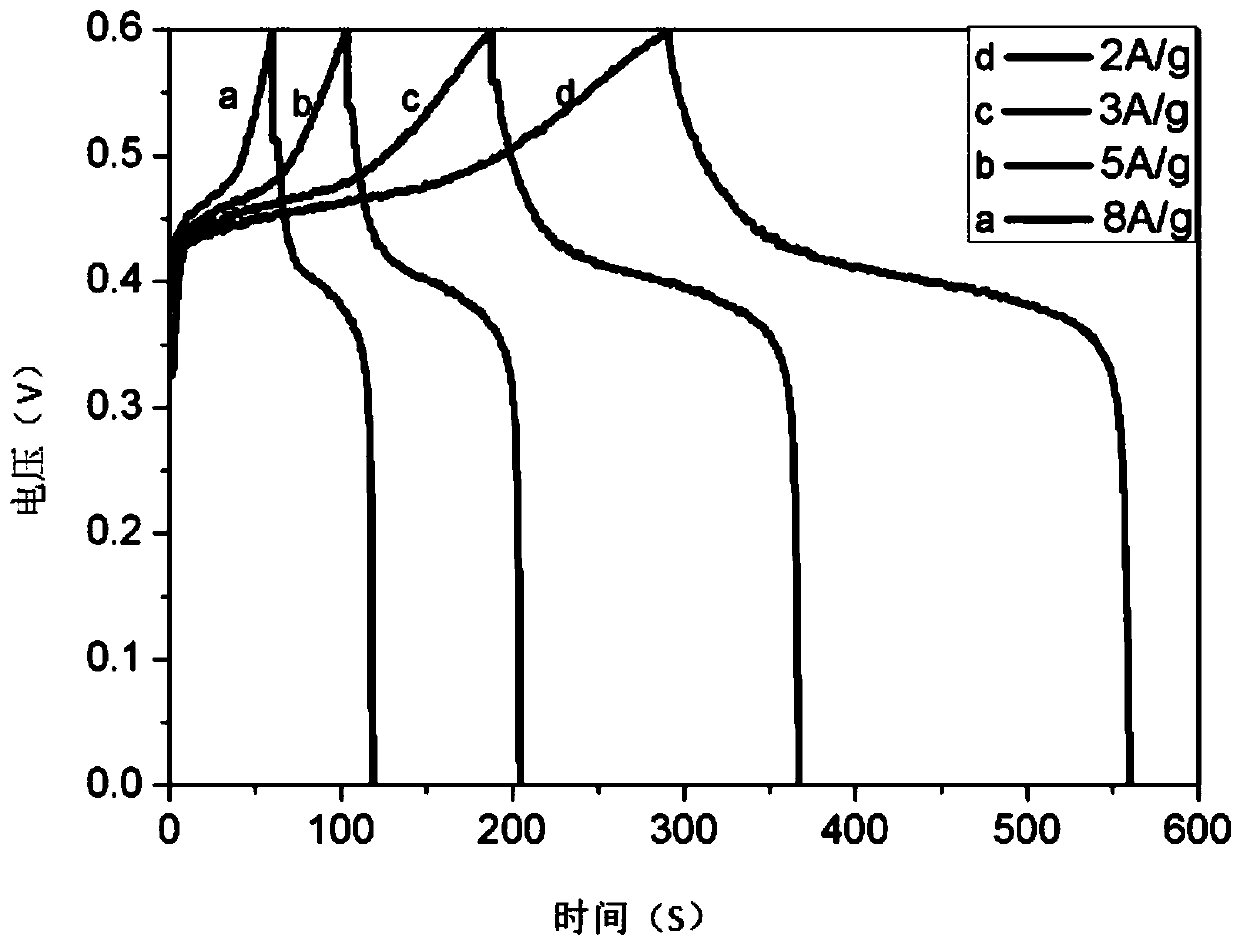

[0029] Embodiment 1, Zn and Mo molar ratio are the Zn of 2:2 3 Mo 2 o 9 Electrode preparation

[0030] (1) Take 0.02M (NH 4 ) 6 Mo 7 o 24 4H 2 O solution and 2M HNO 3 The solution was mixed uniformly at a volume ratio of 2:1, then placed in a water bath at 85°C and heated for 60 minutes, and the resulting product was filtered and dried to obtain MoO 3 nano precursors;

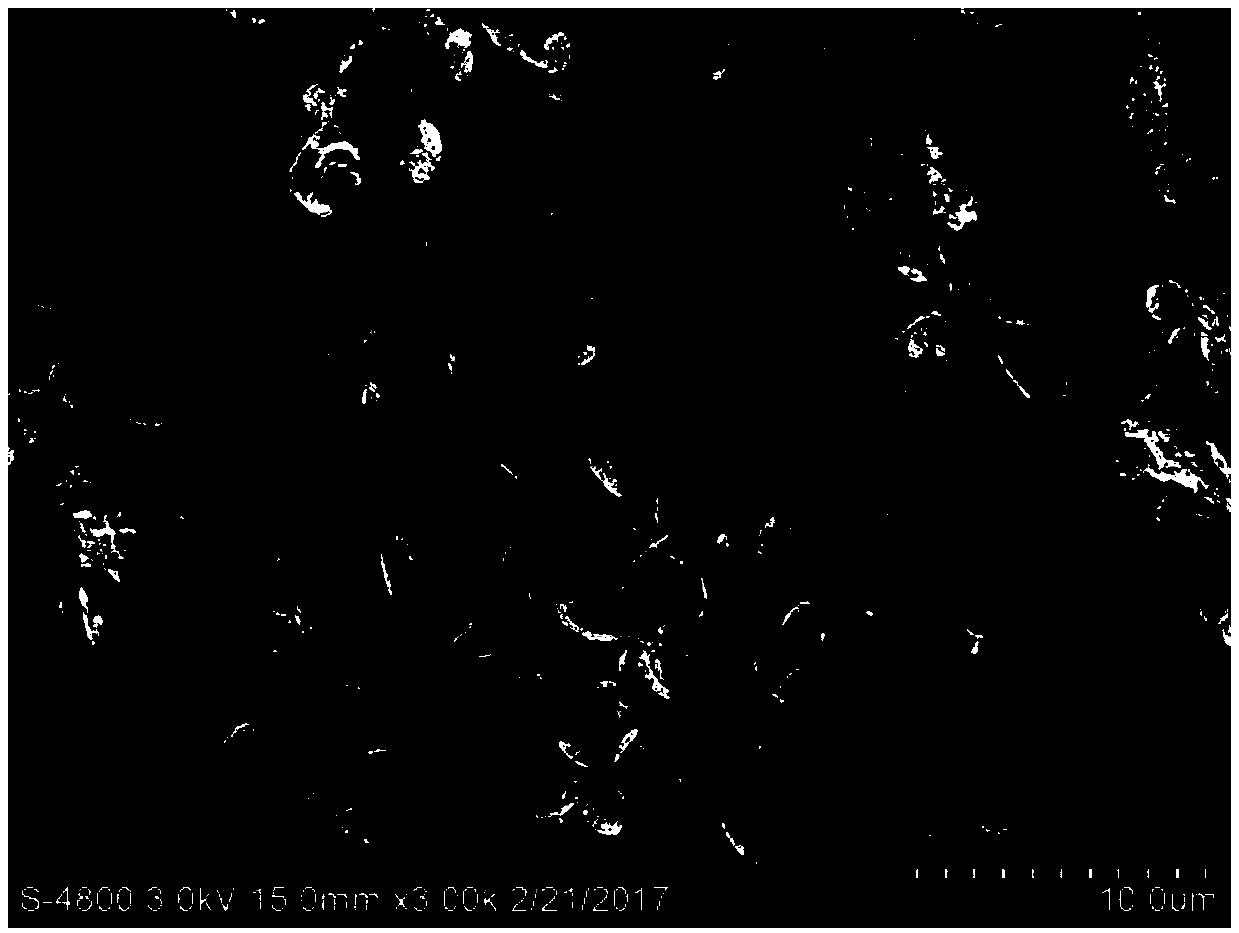

[0031] (2) 0.288g (molar weight is 2mmol) MoO 3 The nano-precursor was placed on a heating stage at 350 °C, and 2 mL, 5 mM zinc acetate (Zn(CH 3 COO) 2 ) in ethanol solution, heated for 0.5h; the mixture was added to the mixed solution of 100mL zinc acetate and urotropine (the concentrations of zinc acetate and urotropine in the mixed solution were both 20mM), reacted at 95°C for 10h, and obtained The product is filtered and dried to obtain ternary Zn 3 Mo 2 o 9 Nano ring flake material;

[0032] (3) The ternary Zn 3 Mo 2 o 9The nano-annular flake material is mixed and dissolved in N-methylpy...

Embodiment 2

[0036] Embodiment 2, Zn and Mo molar ratio are the Zn of 3:2 3 Mo 2 o 9 Electrode preparation

[0037] (1) Take 0.02M (NH 4 ) 6 Mo 7 o 24 4H 2 O solution and 2M HNO 3 The solution was mixed uniformly at a volume ratio of 2:1, then placed in a water bath at 85°C and heated for 60 minutes, and the resulting product was filtered and dried to obtain MoO 3 nano precursors;

[0038] (2) 0.288g MoO 3 The nano-precursor was placed on a heating stage at 350 °C, and 2 mL, 5 mM zinc acetate (Zn(CH 3 COO) 2 ) in ethanol solution, heated for 0.5h; the mixture was added to the mixed solution of 150mL zinc acetate and urotropine (the concentrations of zinc acetate and urotropine in the mixed solution were both 20mM), reacted at 95°C for 10h, and obtained The product is filtered and dried to obtain ternary Zn 3 Mo 2 o 9 Nano ring flake material;

[0039] (3) The ternary Zn 3 Mo 2 o 9 The nano-annular flake material is mixed and dissolved in N-methylpyrrolidone as an active ...

Embodiment 3

[0048] Embodiment 3, the Zn that Zn and Mo molar ratio are 4:2 3 Mo 2 o 9 Electrode preparation

[0049] (1) Take 0.02M (NH 4 ) 6 Mo 7 o 24 4H 2 O solution and 2M HNO 3 The solution was mixed uniformly at a volume ratio of 2:1, then placed in a water bath at 85°C and heated for 60 minutes, and the resulting product was filtered and dried to obtain MoO 3 nano precursors;

[0050] (2) 0.288g MoO 3 The nano-precursor was placed on a heating stage at 350 °C, and 2 mL, 5 mM zinc acetate (Zn(CH 3 COO) 2 ) in ethanol solution, heated for 0.5h; the mixture was added to the mixed solution of 200mL zinc acetate and urotropine (the concentrations of zinc acetate and urotropine in the mixed solution were both 20mM), reacted at 95°C for 10h, and obtained The product is filtered and dried to obtain ternary Zn 3 Mo 2 o 9 Nano ring flake material;

[0051] (3) The ternary Zn 3 Mo 2 o 9 The nano-annular flake material is mixed and dissolved in N-methylpyrrolidone as an activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com