A kind of preparation method of flower-like molybdenum disulfide high-performance supercapacitor electrode

A supercapacitor and molybdenum disulfide technology, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, molybdenum sulfide, etc., to achieve the effect of low price, simple process operation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、160

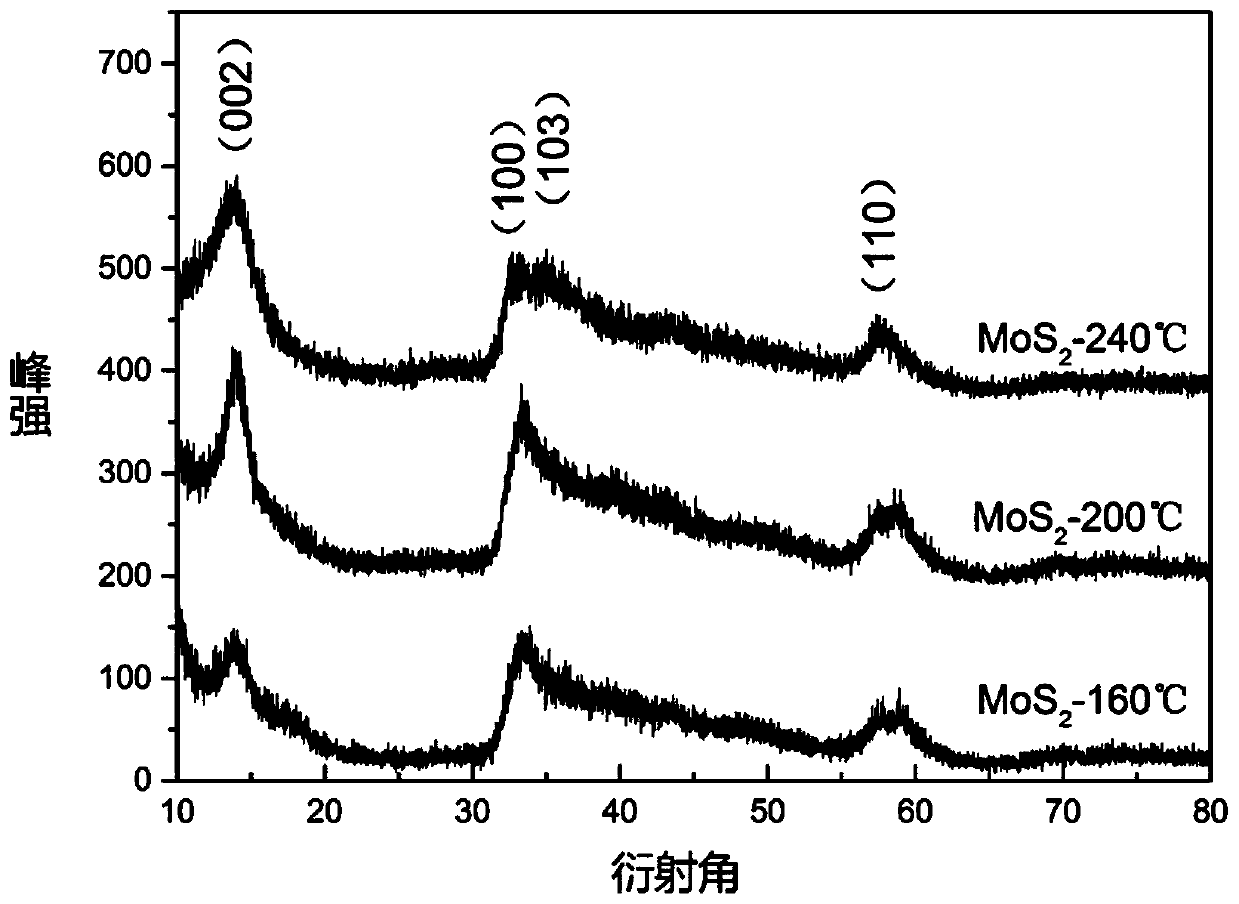

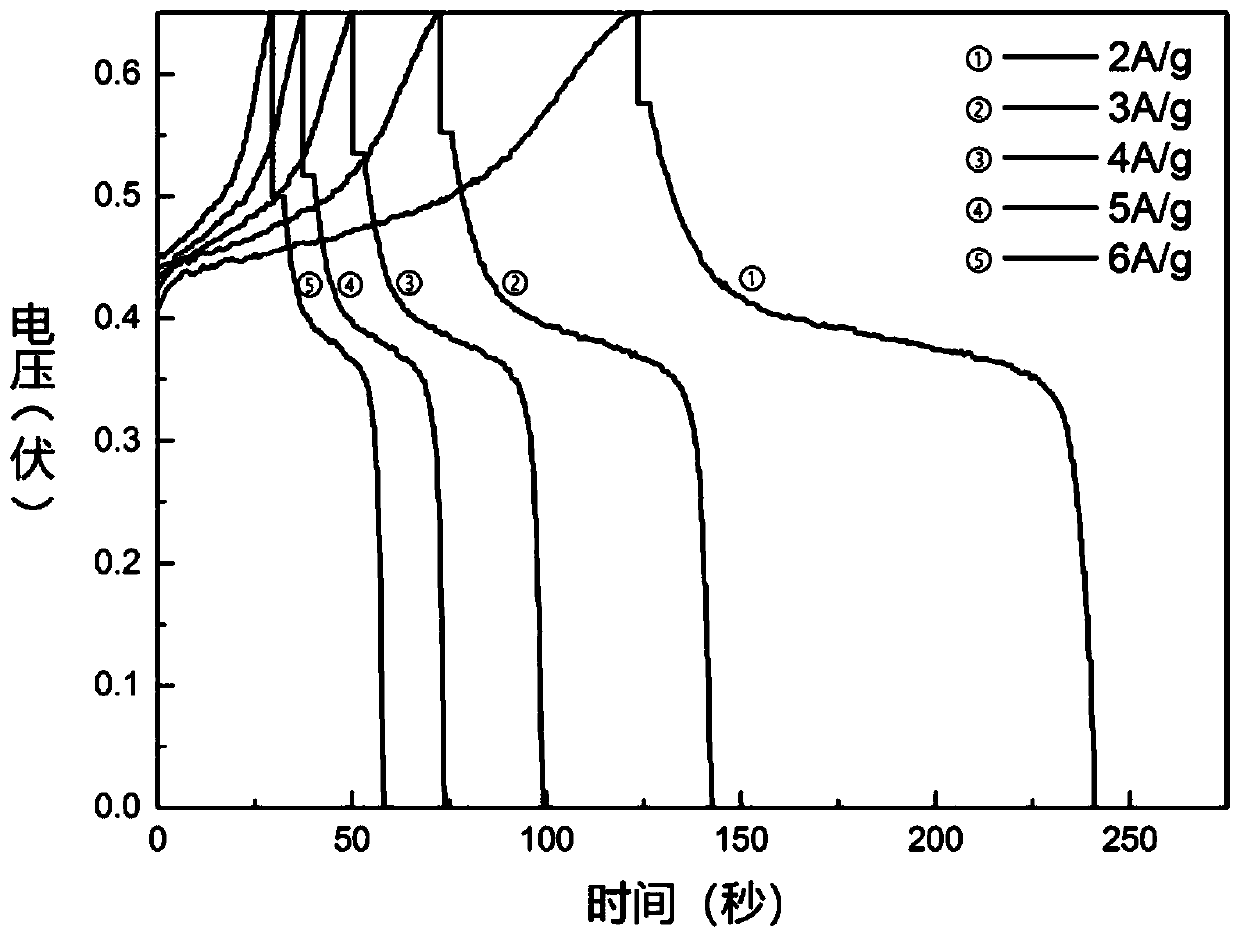

[0031] Example 1, MoS at 160°C 2 Electrode preparation

[0032] (1) Weigh 0.5g molybdenum sheet (thickness is 0.03mm), 0.4g thiourea powder is placed in the stainless steel reactor of 100mL polytetrafluoroethylene liner, then measure 15mL mass concentration and be that the nitric acid of 68% is poured into reaction The inner lining of the kettle was sealed under high pressure; then the reaction kettle was placed in a high-temperature furnace at 200 ° C for 24 hours; after the reaction was completed, it was naturally cooled to room temperature, and the obtained product was washed with ethanol and distilled water, and finally dried in vacuum to obtain the intermediate product MoO 3 .

[0033] (2) Take 0.1536g intermediate product MoO 3 and 0.6113g of thiourea were added to a beaker with 40mL of distilled water, stirred magnetically at room temperature for 60 minutes, then transferred to a 100mL polytetrafluoroethylene-lined stainless steel reactor and sealed, and reacted at 16...

Embodiment 2、200

[0039] Example 2, MoS at 200°C 2 Electrode preparation

[0040] (1) Weigh 0.5g molybdenum sheet (thickness is 0.03mm), 0.4g thiourea powder is placed in the stainless steel reaction kettle of 100mL volume polytetrafluoroethylene liner, then measure 15mL mass concentration and be that the nitric acid of 68% is poured into The reaction kettle was lined and sealed under high pressure; then the reaction kettle was placed in a high-temperature furnace at 200°C for 24 hours; after the reaction, it was naturally cooled to room temperature, and the obtained product was washed with ethanol and distilled water, and finally vacuum-dried to obtain the intermediate product MoO 3 .

[0041] (2) Take 0.1536g intermediate product MoO 3 and 0.6113g of thiourea were added to a beaker with 40mL of distilled water, stirred magnetically at room temperature for 60 minutes, then transferred to a 100mL polytetrafluoroethylene-lined stainless steel reactor and sealed, and reacted at 200°C for 24 hou...

Embodiment 3、240

[0050] Example 3, MoS at 240°C 2 Electrode preparation

[0051] (1) Weigh 0.5g molybdenum sheet (thickness is 0.03mm), 0.4g thiourea powder is placed in the stainless steel reaction kettle of 100mL volume polytetrafluoroethylene liner, then measure 15mL mass concentration and be that the nitric acid of 68% is poured into The reaction kettle was lined and sealed under high pressure; then the reaction kettle was placed in a high-temperature furnace at 200°C for 24 hours; after the reaction, it was naturally cooled to room temperature, and the obtained product was washed with ethanol and distilled water, and finally vacuum-dried to obtain the intermediate product MoO 3 .

[0052] (2) Take 0.1536g intermediate product MoO 3 and 0.6113g of thiourea were added to a beaker with 40mL of distilled water, stirred magnetically at room temperature for 60 minutes, then transferred to a 100mL polytetrafluoroethylene-lined stainless steel reactor and sealed, and reacted at 240°C for 24 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com