Stable GO-NiCoS-NiMoLDH composite material and preparation method and application thereof

A technology of composite materials and matrix materials, applied in stable GO-NiCoS-NiMoLDH composite materials and its preparation and application fields, can solve the problems of poor rate performance and cycle stability, redox reaction damage, chemical instability, etc., to achieve Improve stability, accelerate the diffusion of ions, and improve the effect of electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A preparation method of a GO-NiCoS-NiMoLDH composite material, the preparation method comprising the following steps:

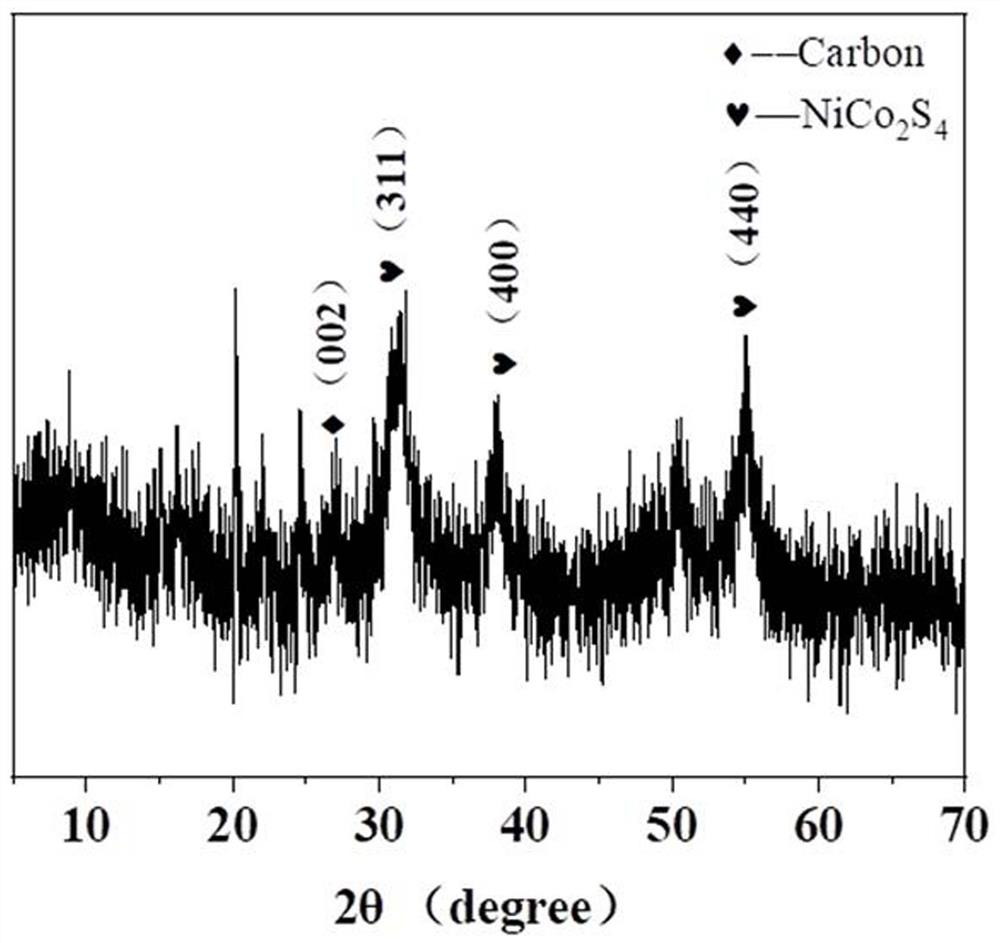

[0061] Step 1, GO-NiCo 2 S 4 The preparation of 2mmol nickel acetate tetrahydrate, 4mmol cobalt acetate tetrahydrate and 6mmol thiourea were dissolved in 40ml ethylene glycol, and then 15ml, 2mg / ml GO aqueous solution was added to obtain the first hydrothermal reaction solution, and then, in The first hydrothermal reaction was carried out under the condition that the hydrothermal temperature was 180°C and the hydrothermal time was 12h. The reaction product was washed with distilled water and absolute ethanol, and then the drying temperature was 60°C and the drying time was 24h. Dry to get GO-NiCo 2 S 4 , referred to as GO-NiCoS;

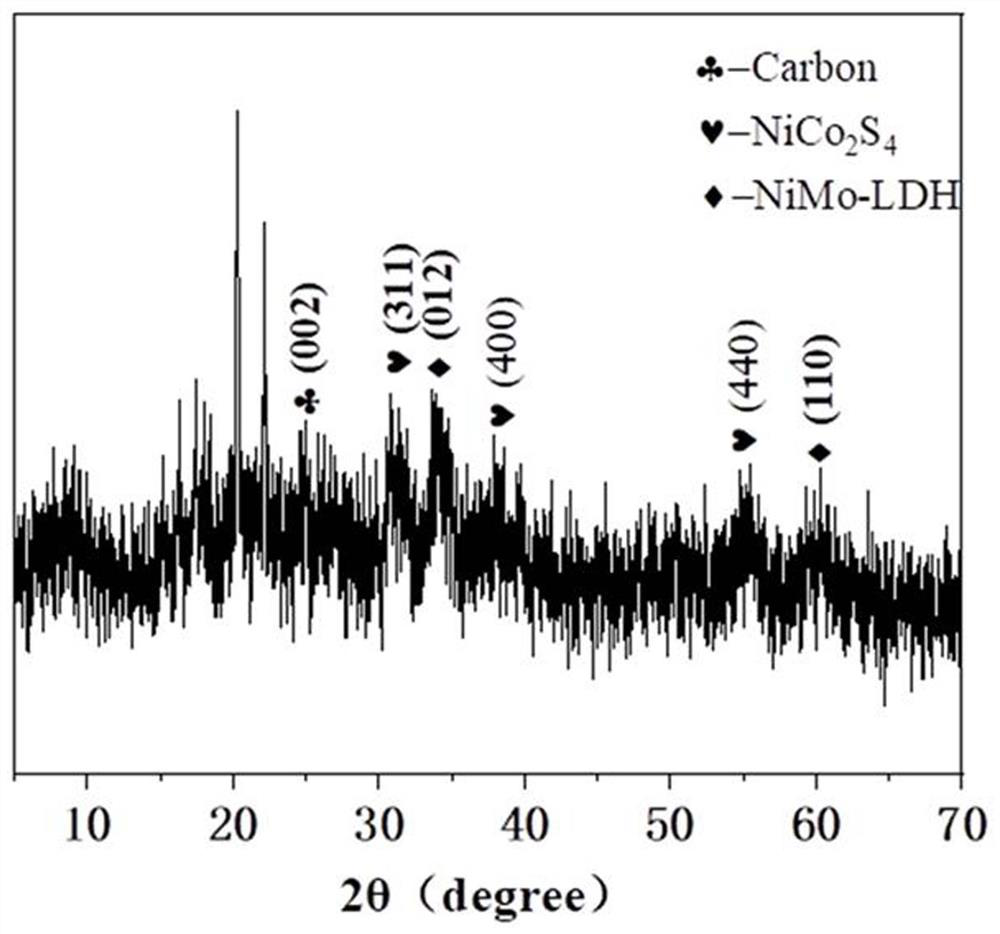

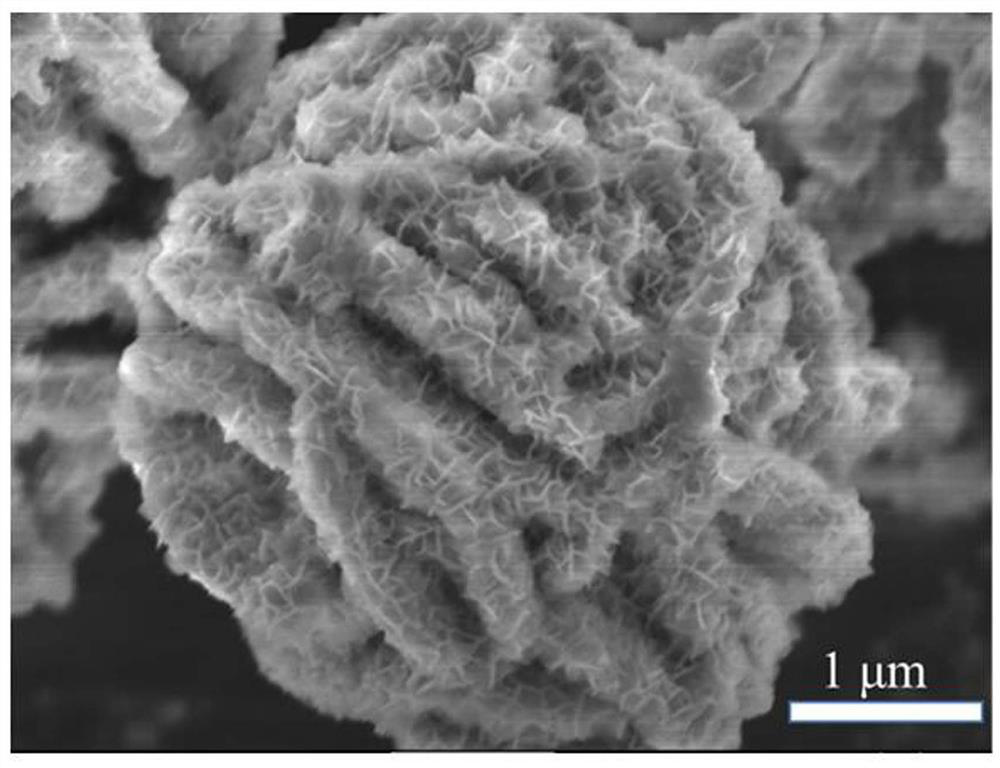

[0062] Step 2, preparation of GO-NiCoS-NiMoLDH, dissolve 2mmol nickel nitrate, 2mmol sodium molybdate and 15mmol urea in 50ml deionized water, stir for 30min to obtain a mixed solution, and then add 0.5 g of GO-NiCo obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com