Concrete wall temperature difference power generation device and manufacturing method of graphene-concrete wall of concrete wall temperature difference power generation device

A concrete wall, thermoelectric power generation technology, applied in circuit devices, battery circuit devices, supply devices, etc., can solve the problems of insignificant temperature difference between cold and hot ends, poor prospects for large-scale application, and damage to the integrity of concrete, etc. Achieve the effect of rapid increase in sunlight absorption efficiency, increased nickel ion precipitation, and superior compression, bending and bending performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

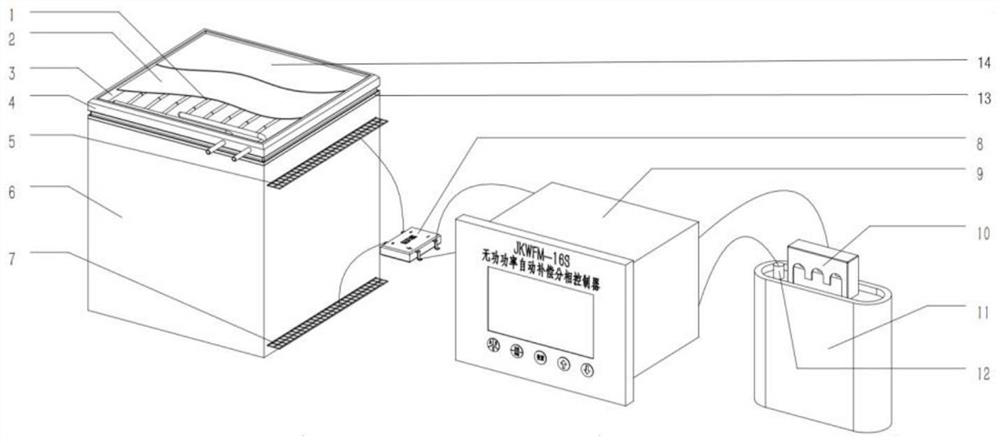

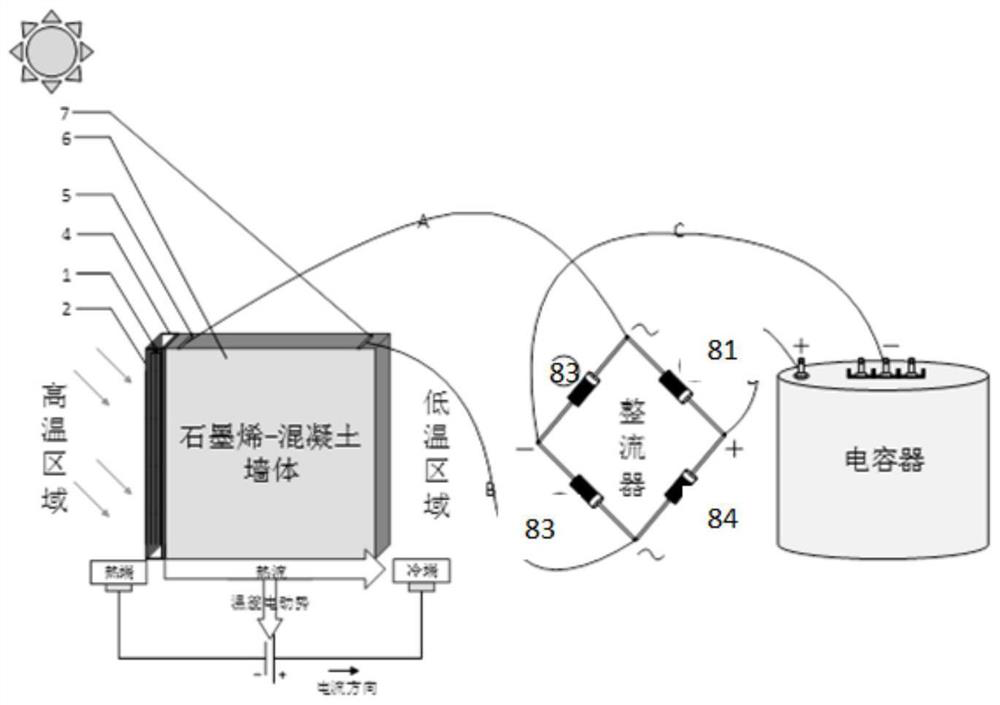

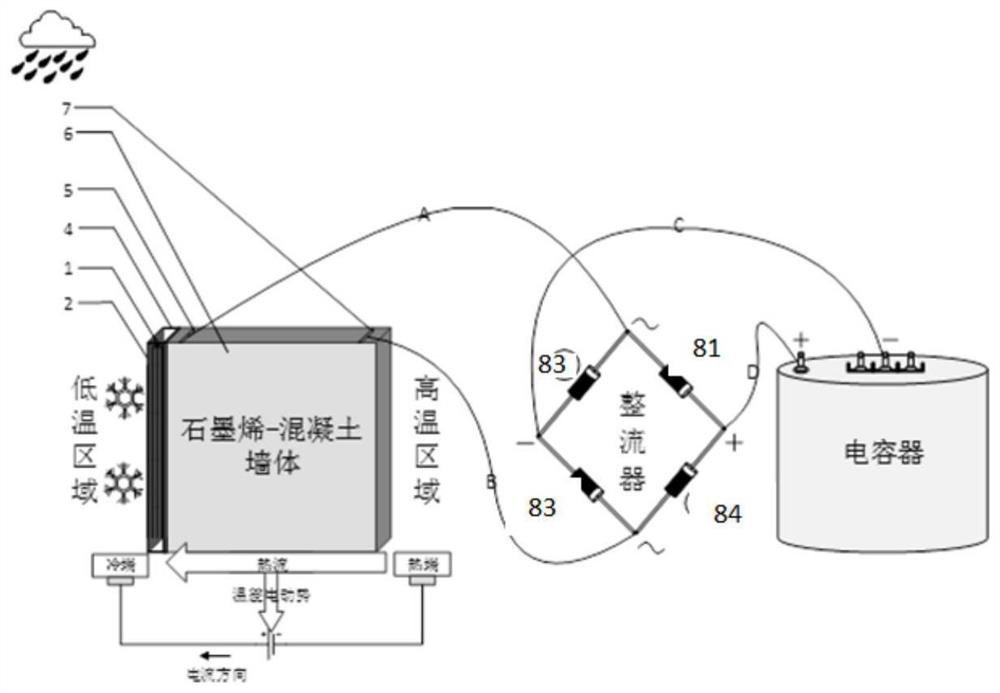

[0041] Such as figure 1 As shown, the concrete wall temperature differential power generation device of the present invention includes a graphene-concrete wall 6, a heat collection system, a control system and a power storage system, and the heat collection system is fixed on the graphene-concrete wall 6, and the graphite The vinyl-concrete wall body 6 is sequentially connected with the control system and the power storage system. The heat collection system includes a red copper flow channel 1 and a blue film plated plate 2, and the red copper flow channel 1 is located between the blue film plated plate 2 and the graphene-concrete wall 6.

[0042]Specifically, the copper flow channel 1 integrating two main channels and eight branch channels is closely bonded to the graphene-concrete wall 6 for direct heat transfer, and the blue film plated plate 2 is covered on the copper flow channel 1 to achieve high-efficiency collection. hot. Optionally, the diameter of the main pipe of ...

Embodiment 2

[0051] The raw material of the graphene-concrete wall of the present invention comprises the following components by weight: 55 parts of cement, 10 parts of fly ash, 40 parts of aggregate, 5 parts of graphene nanosheets, 1 part of polycarboxylate superplasticizer, 5 parts of graphene oxide and 75 parts of water. The cement is ordinary Portland cement, its 28-day compressive strength ≥ 42.5, 28-day flexural strength ≥ 6.5, specific surface area ≥ 300. Graphene nanosheets have a thickness of 10-20nm and a surface area of 50-80m 2 g -1 . Graphene oxide can be prepared with reference to patent CN202110124791.9.

[0052] Graphene-concrete wall of the present invention is prepared in the following manner:

[0053] 1) Put the graphene nanosheets and cement into a planetary ball mill with zirconia balls, and use the ball milling method to make the graphene nanosheets evenly distributed in the cement to obtain graphene cement, wherein the speed of the ball mill is 600r / min, and t...

Embodiment 3

[0059] The raw material of the graphene-concrete wall of the present invention comprises the following components by weight: 75 parts of cement, 20 parts of fly ash, 65 parts of aggregate, 10 parts of graphene nanosheets, 2 parts of polycarboxylate superplasticizer, 10 parts of graphene oxide and 90 parts of water.

[0060] Graphene-concrete wall of the present invention is prepared in the following manner:

[0061] 1) Put the graphene nanosheets and cement into a planetary ball mill with zirconia balls, and use the ball milling method to make the graphene nanosheets evenly distributed in the cement to obtain graphene cement, wherein the speed of the ball mill is 600r / min, and the scheduled ball milling time is 12h.

[0062] 2) Graphene oxide is mixed with a dispersant and an auxiliary dispersant, added with water and stirred for pre-dispersion to obtain a pre-dispersion, and the pre-dispersion is ultrasonically dispersed with an ultrasonic disperser to obtain a graphene dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com