Demagnetization method for welding longitudinal joint groove of single pile foundation

A technology of monopile foundation and degaussing method, applied in magnetic objects, electrical components, circuits, etc., can solve the problems of high cost, inapplicability, complicated operation process, etc., to eliminate stress, improve stress condition, and simplify degaussing operation. effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: (Taking successful trial welding as an example)

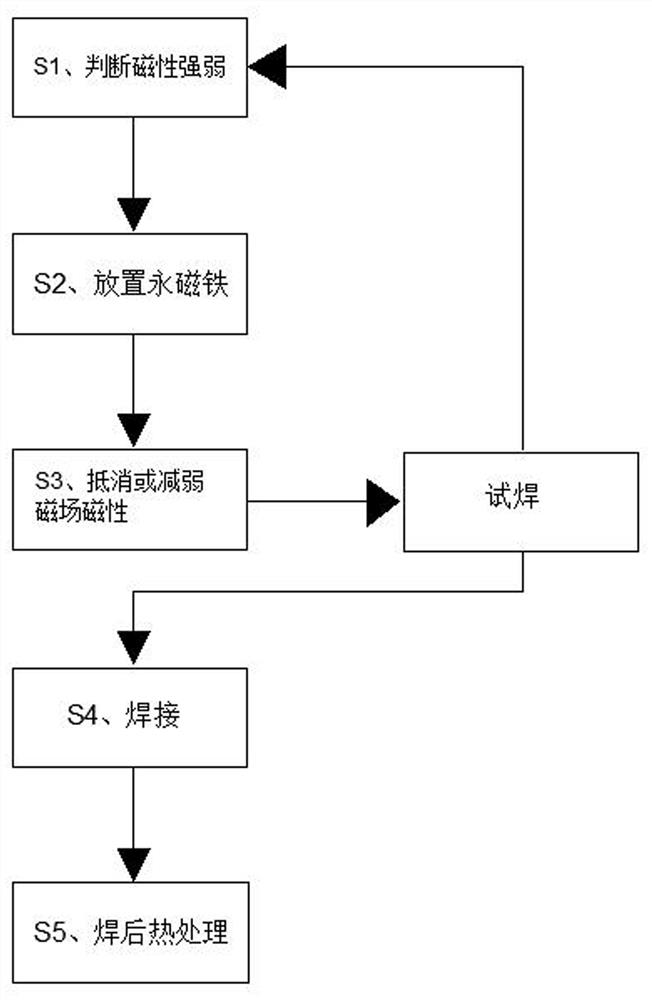

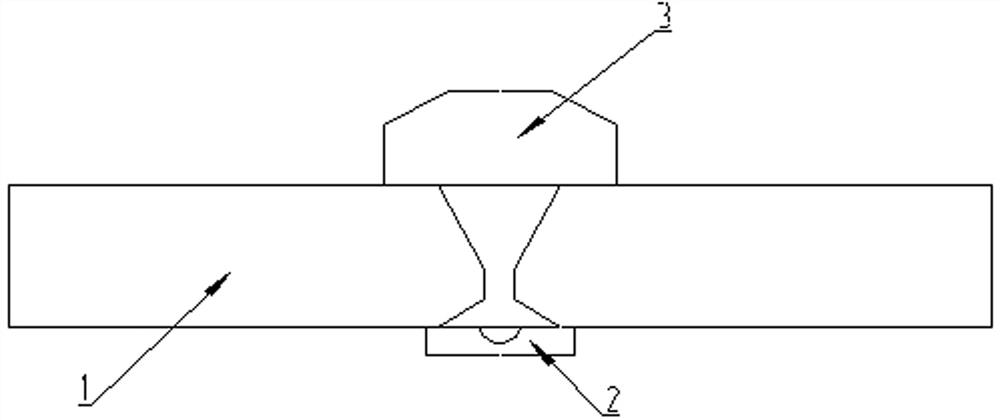

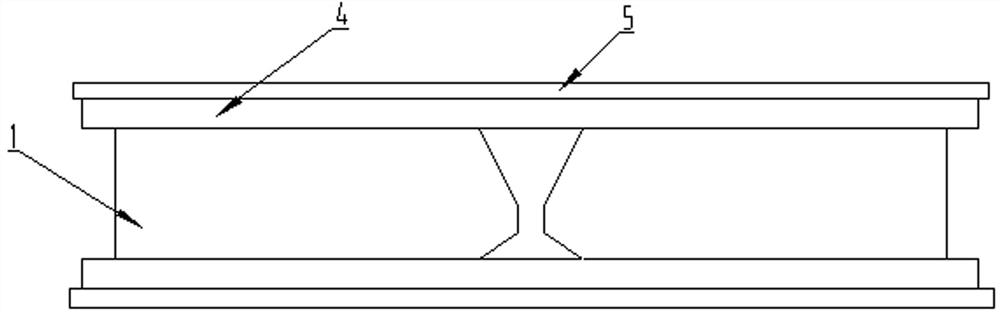

[0023] see figure 1 , a method for degaussing the longitudinal seam groove of a monopile foundation, comprising the following specific steps: first, a row of iron blocks 2 are placed under the monopile foundation longitudinal seam groove 1 with magnetism, so that the monopile foundation longitudinal seam Groove 1 can judge the strength of magnetism under the adsorption of iron block 2 (such as figure 2 shown); then remove the five-ton permanent magnet 3 on the three magnetic suction cranes, and place the five-ton permanent magnet 3 equidistantly on the two ends and the middle of the longitudinal seam groove 1 of the monopile foundation; The suction machine adjusts the position and direction of the permanent magnet 3. When the position and direction of the permanent magnet 3 are adjusted, the iron block 2 will fall, that is, the permanent magnet 3 will generate a magnetic field opposite to that of the longitu...

Embodiment 2

[0024] Example 2: (take the failure of trial welding as an example)

[0025] In this embodiment, the degaussing method of the longitudinal seam groove of the single pile foundation is consistent with that of Embodiment 1, only the trial welding is unsuccessful, that is, after the iron block 2 is dropped, the longitudinal seam groove is tested by flux-cored gas shielded welding , the phenomenon of arc magnetic deflection and a large amount of spatter still appeared after the test welding. At this time, considering whether the judgment of the magnetic field was wrong, a row of iron blocks 2 was placed under the longitudinal seam groove 1 of the monopile foundation again. If the iron blocks 2 Can not be absorbed to the longitudinal seam groove 1 of the monopile foundation, that is, the magnetic field judgment is correct, and then check whether there is any external factor at the longitudinal seam groove 1 of the monopile foundation, which should be eliminated in time. , there wil...

Embodiment 3

[0026] Example 3: (take the failure of trial welding as an example)

[0027] In this example, the degaussing method of the longitudinal seam groove of the monopile foundation is consistent with that of Example 1, and only the heat treatment process is inconsistent with the heating and degaussing of the weld, that is, when the heating temperature is higher than the 770°C Curie temperature of the steel plate of the monopile foundation , the steel plate of the single-pile foundation will become a paramagnet, so that the steel plate of the single-pile foundation has a weak response to the magnetic field, and the inductance will gradually decrease until it disappears.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com