Automatic iron nail and scrap iron dispersing and collecting device used after iron nail polishing

A collection device and iron nail technology, applied in solid separation, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of wasting iron filings, failure to collect, unstable charge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

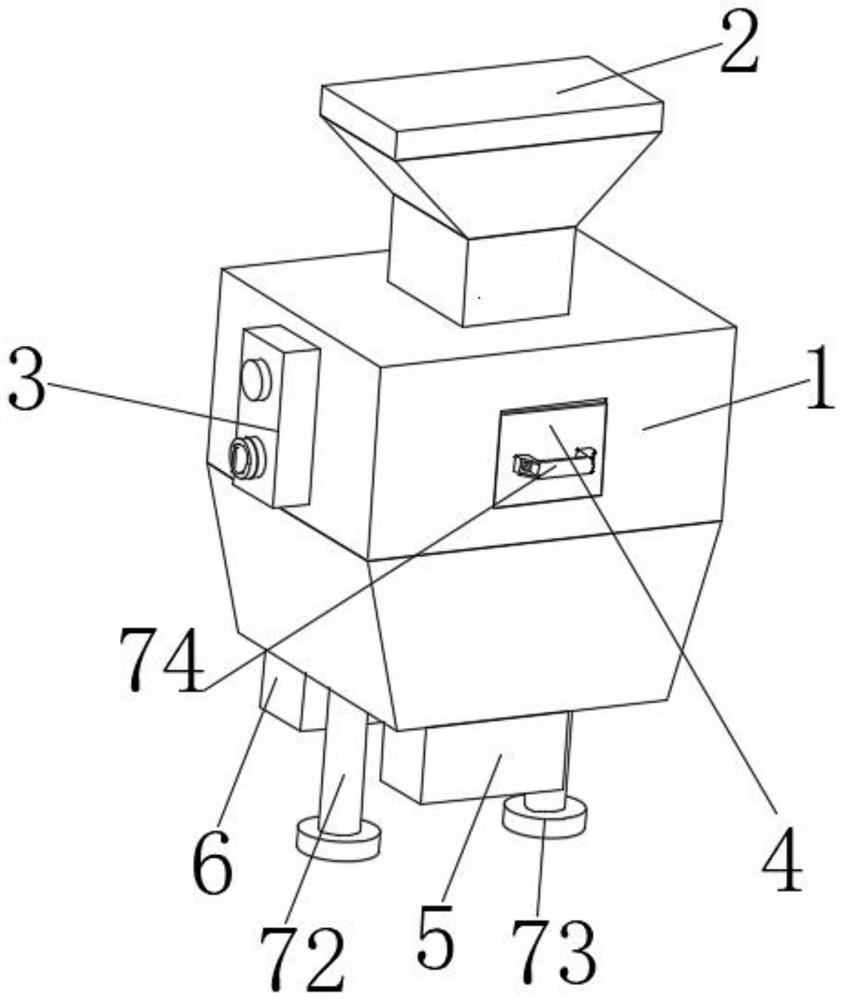

[0023]ExampleFigure 1 - Figure 2 The display:

[0024]The present invention provides a schematic diagram of an automated iron nail iron bile discrete collection apparatus for a nail polishing, wherein

[0025]Including the body 1, the tip end of the body 1 is provided with a feeding port 2, and a controller 3 is provided on the side wall of the body 1, and a front side of the body 1 is provided with a visual window 4, the bottom end of the body 1. A iron nail discharge box 5 and iron bull delivery box 6 are provided, and the controller 3 is connected and a generator 7 is provided on the inner wall of the body 1, and a bidirectional movement is provided in the bottom end of the generator 7. The rod 8 is provided with a push rod 9 that is fitted to it, and the push rod 9 is provided with a sensing contact with which it cooperates, and the sense contact one 10 is provided with it. Induction contact two 11, the inner wall of the top end of the body 1 is symmetrically provided with a body conn...

Embodiment 2

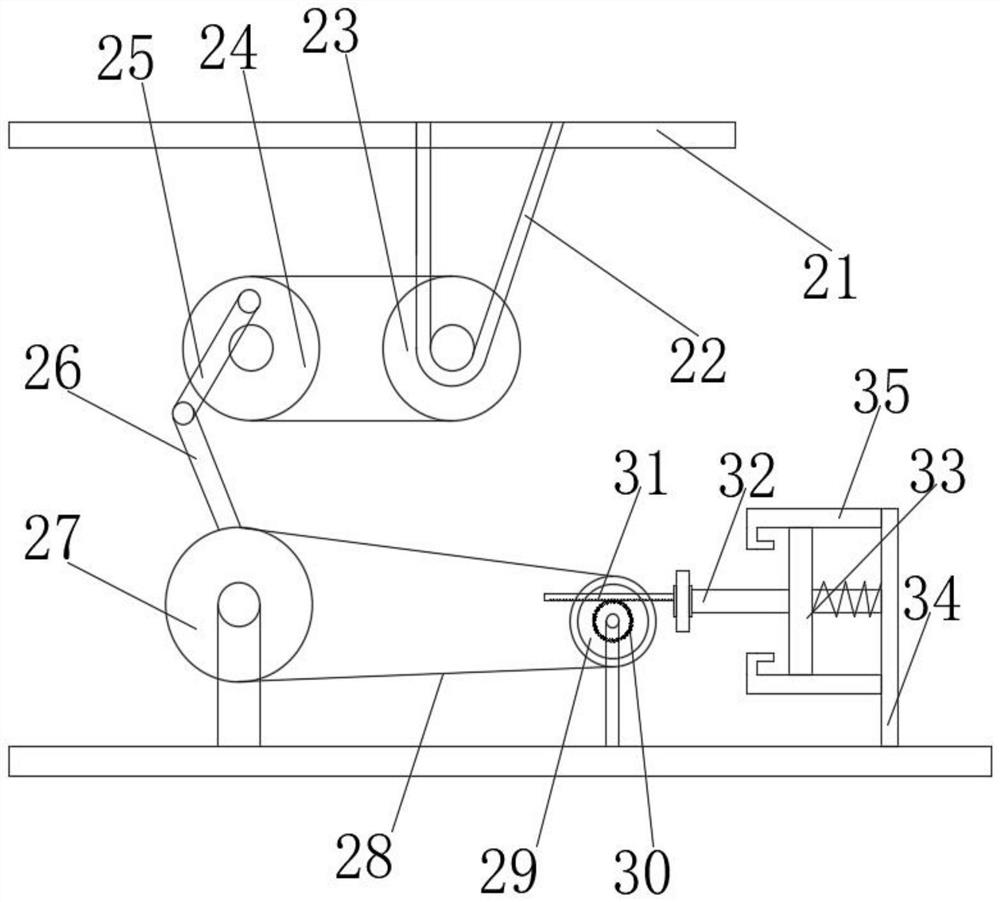

[0028]ExampleFigure 3 - Figure 5The display:

[0029]The present invention provides a schematic diagram of a discrete collection apparatus for automated iron nails after a nail polishing, wherein

[0030]Including the body 1, the tip end of the body 1 is provided with a feeding port 2, and a controller 3 is provided on the side wall of the body 1, and a front side of the body 1 is provided with a visual window 4, the bottom end of the body 1. A iron nail discharge box 5 and iron bull delivery box 6 are provided, and the controller 3 is connected and a generator 7 is provided on the inner wall of the body 1, and a bidirectional movement is provided in the bottom end of the generator 7. The rod 8 is provided with a push rod 9 that is fitted to it, and the push rod 9 is provided with a sensing contact with which it cooperates, and the sense contact one 10 is provided with it. Induction contact two 11, the inner wall of the top end of the body 1 is symmetrically provided with a body connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com