Polycrystalline silicon surface metal detection sample preparation method and detection method

A surface metal and detection sample technology, which is applied in the preparation of polysilicon surface metal detection samples and in the field of polysilicon surface metal detection, can solve the problems of inability to accurately reflect the metal impurity content on the surface of polysilicon products, increase the difficulty of operation, and long detection cycle, etc., to shorten the preparation time, improve detection accuracy, and fast sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

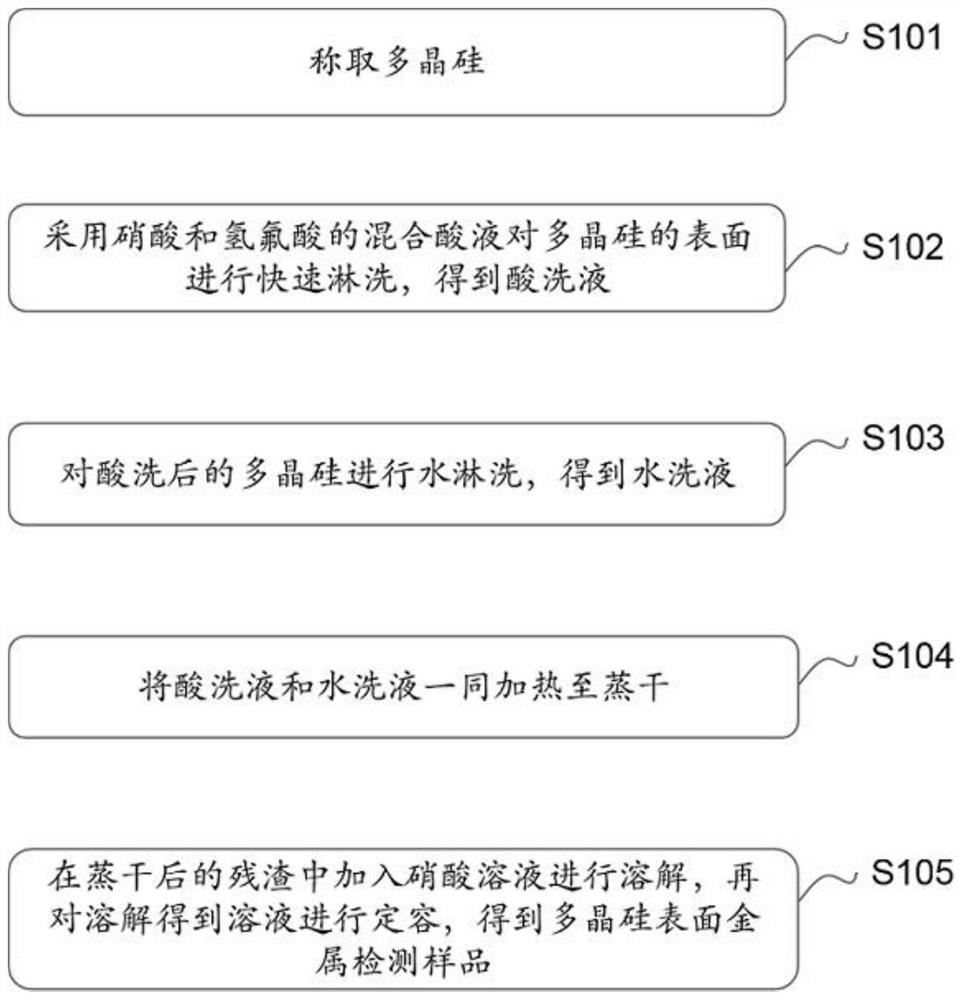

[0029] In view of the existing technology, the leaching time in the preparation process of the metal detection sample on the polysilicon surface is long, and impurities such as K, Ca, Al, Fe are easily introduced from the introduced environment, resulting in long detection cycle and low detection accuracy. Therefore, the present invention discloses a method for preparing a polysilicon surface metal detection sample, comprising:

[0030] S101 sampling: weighing polysilicon;

[0031] S102 pickling: using a mixed acid solution of nitric acid and hydrofluoric acid to quickly rinse the surface of the polysilicon to obtain a pickling solution;

[0032] S103 Washing with water: washing the pickled polysilicon with water to obtain a washing solution;

[0033] S104 Evaporation: heating the pickling liquid and water washing liquid together to evaporate to dryness;

[0034] S105 Constant volume: adding nitric acid to the evaporated residue to dissolve, and then constant volume of the d...

Embodiment 1

[0039] Such as figure 1 As shown, this embodiment discloses a method for preparing a polysilicon surface metal detection sample, including:

[0040] S101 Sampling: weighing polysilicon.

[0041] Among them, considering that too much polysilicon will increase the amount of acid solution and water required for subsequent pickling and water washing, prolong the time required for subsequent evaporation and other processes, and reduce the sample preparation speed, too little polysilicon will increase the difficulty of operation , increasing the operating error. Therefore, after a large number of tests, the amount of polysilicon in this embodiment is preferably 30-50 g, and since the content of metal on the surface of polysilicon is at the ppbw level, the mass of polysilicon weighed should be accurate to 0.0001 g.

[0042] S102 pickling: using a mixture of nitric acid and hydrofluoric acid to quickly rinse the surface of the polysilicon to obtain a pickling solution.

[0043] Amo...

preparation example 1

[0059] This preparation example discloses a method for preparing a polysilicon surface metal detection sample, including:

[0060] (1) Weigh 30.0000 g of polysilicon, and put it into a polytetrafluoroethylene beaker.

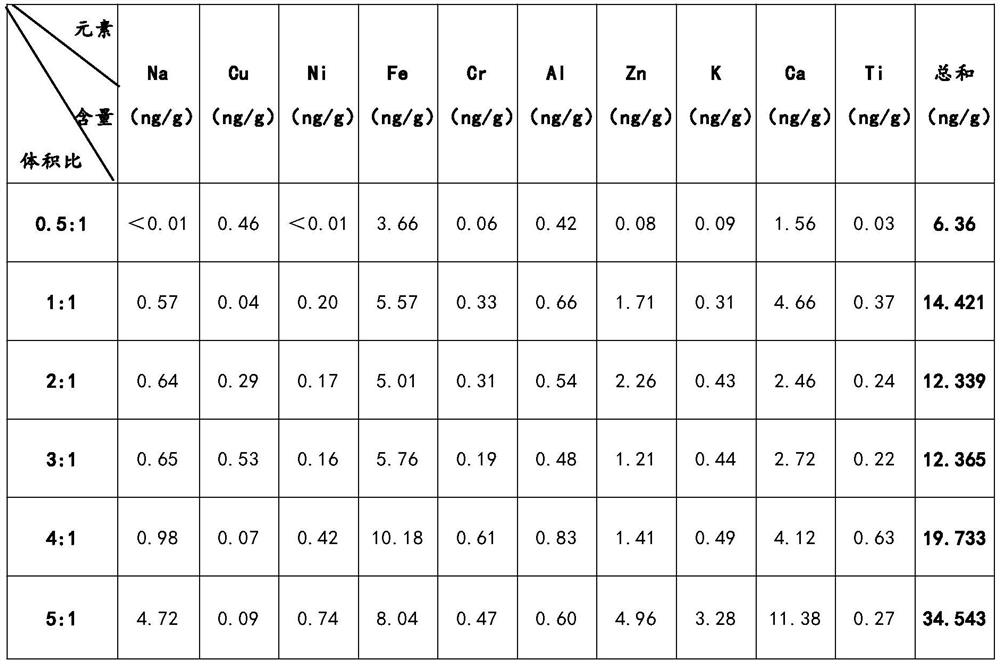

[0061] (2) Place the above-mentioned beaker filled with polysilicon in a fume hood with a cleanliness level of ten; use a nitric acid solution with a mass fraction of 55% and a hydrofluoric acid solution with a mass fraction of 38% in a volume ratio of 2:1. The resulting mixed acid solution; use a pipette to take 10ml of the above mixed acid solution, and quickly pour it onto the polysilicon surface at a rate of 2 to 3 drops / second (the amount of each drop is controlled at about 0.2ml) (i.e. acid rinsing). The metal impurities on the polysilicon surface are rapidly dissolved to obtain a pickling solution containing metal impurities.

[0062] (3) Slowly pour 5ml of deionized water onto the surface of the polysilicon after rinsing with the mixed acid solution (ie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com