Zein/polyphenol/nano-zinc oxide composite fiber membrane and preparation method thereof

A technology of zein and nano-zinc oxide, which is applied in fiber processing, fiber chemical characteristics, single-component protein rayon, etc., can solve the problem of not fundamentally solving food preservation problems, increasing the burden on the earth, resource waste environment, etc. problem, achieve the effect of reducing water loss, inhibiting growth, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

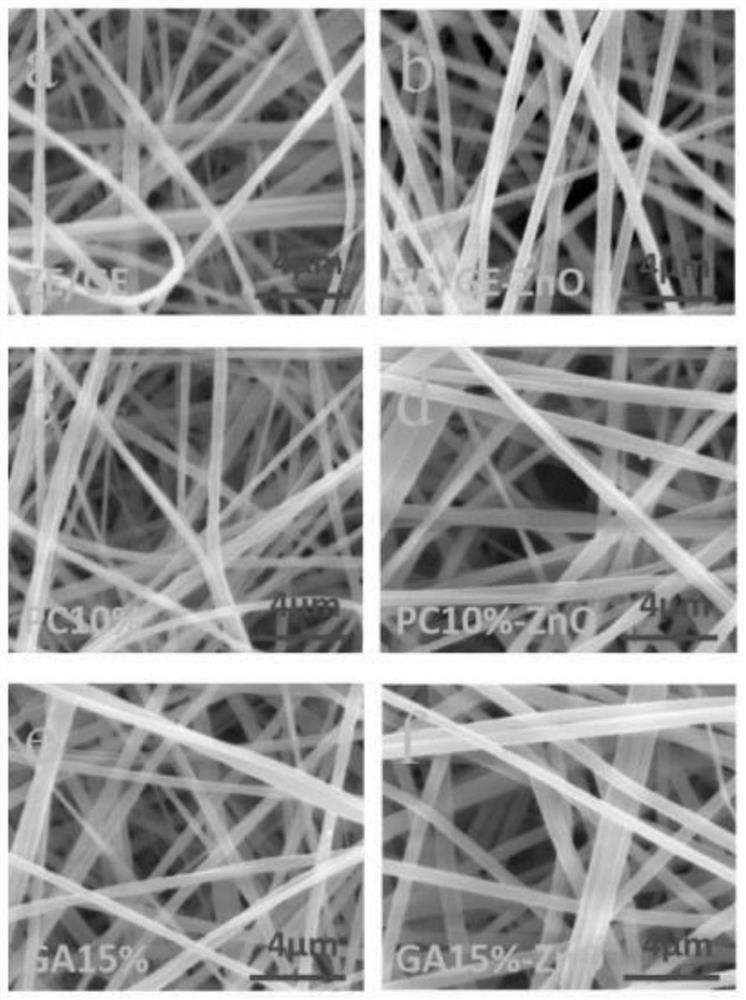

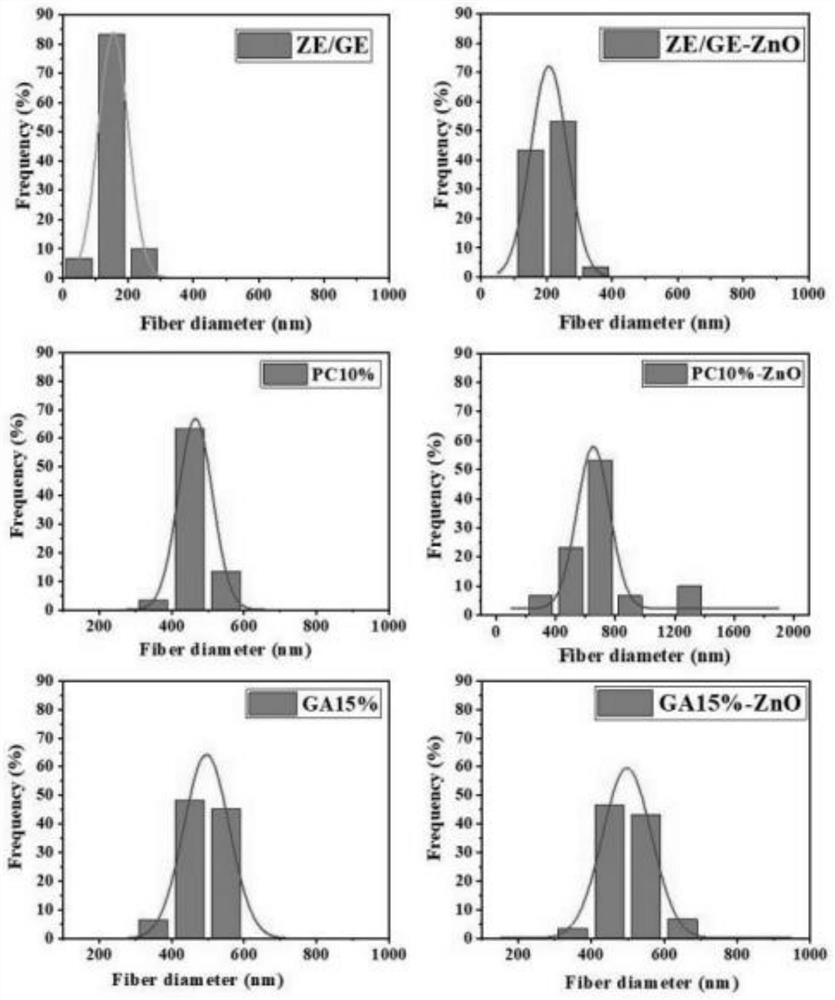

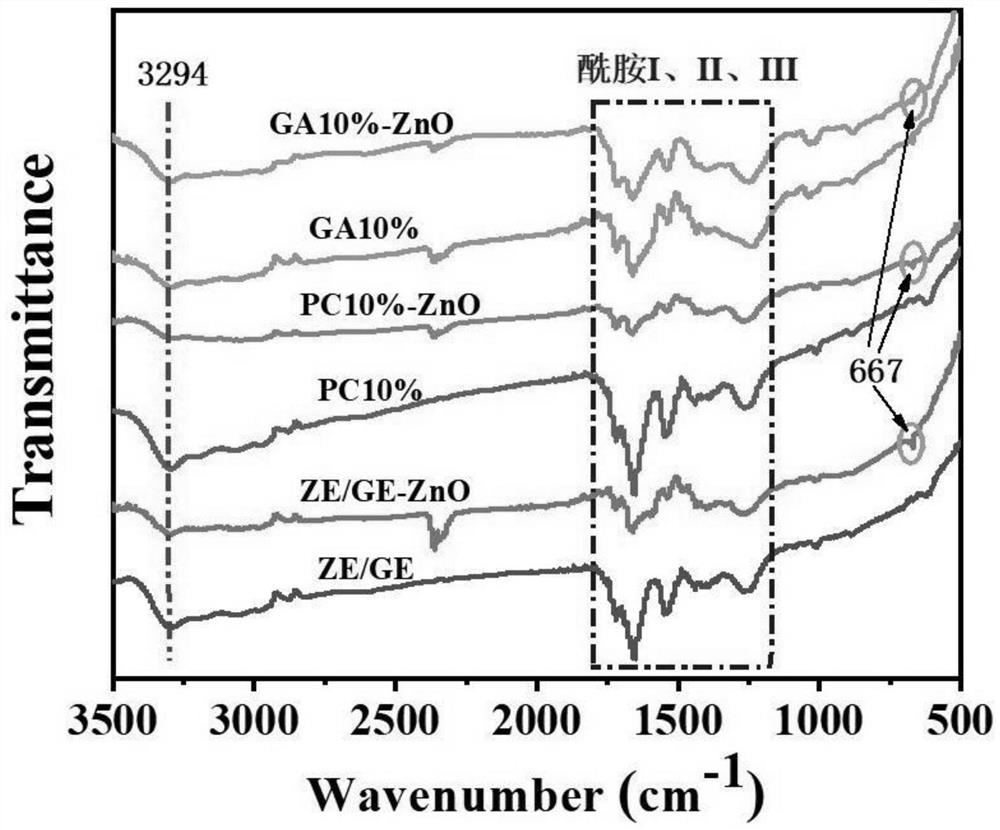

[0044] The embodiment of the present invention discloses a zein / polyphenol / nano-zinc oxide composite fiber membrane and a preparation method thereof, which specifically includes the following steps:

[0045] (1) Dissolving zein in an aqueous acetic acid solution, then adding gelatin and mixing evenly to obtain a zein solution;

[0046] The mass ratio of acetic acid to water in the acetic acid aqueous solution is 8:2; the mass volume ratio of zein to ethanol aqueous solution is 1g / 10mL, and the mass ratio of gelatin to zein is (1~5):(5~9 );

[0047] (2) adding polyphenols to the above-mentioned zein solution, and then heating and stirring to obtain a corn / polyphenol solution;

[0048] The polyphenols are ferulic acid, quercetin, gallic acid or proanthocyanidins; the mass fraction of polyphenols is 5-15%; the heating temperature is 42°C, the stirring time is 30min, and the stirring speed is 400r / min

[0049] (3) Add nano-zinc oxide to the above-mentioned corn / polyphenol soluti...

Embodiment 1

[0054] Embodiment 1 of the present invention discloses a zein / polyphenol / nano-zinc oxide composite fiber membrane and a preparation method thereof, specifically comprising the following steps:

[0055] (1) Dissolving zein in an aqueous acetic acid solution, then adding gelatin and mixing evenly to obtain a zein solution;

[0056] The mass ratio of acetic acid to water in the acetic acid aqueous solution is 8:2; the mass volume ratio of zein to ethanol aqueous solution is 1g / 10mL, and the mass ratio of gelatin to zein is 4:9;

[0057] (2) Add proanthocyanidins to the above-mentioned zein solution so that the mass fraction of proanthocyanidins is 10%, and then heat to 42° C. and stir for 30 minutes to obtain a corn / polyphenol solution; the stirring speed is 400 r / min;

[0058] (3) Add nano-zinc oxide to the above-mentioned corn / polyphenol solution, and undergo ultrasonic treatment to obtain an electrospinning solution; the mass fraction of nano-zinc oxide is 5%, the ultrasonic t...

Embodiment 2

[0063] Embodiment 2 of the present invention discloses a zein / polyphenol / nano-zinc oxide composite fiber membrane and a preparation method thereof, specifically comprising the following steps:

[0064] (1) Dissolving zein in an aqueous acetic acid solution, then adding gelatin and mixing evenly to obtain a zein solution;

[0065] The mass ratio of acetic acid to water in the acetic acid aqueous solution is 8:2; the mass volume ratio of zein to ethanol aqueous solution is 1g / 10mL, and the mass ratio of gelatin to zein is 4:6;

[0066] (2) Add gallic acid to the above-mentioned zein solution, so that the mass percentage of gallic acid is 15%, and then heat to 42° C. and stir for 30 minutes to obtain a corn / polyphenol solution; the stirring speed is 400 r / min;

[0067] (3) Add nano-zinc oxide to the above-mentioned corn / polyphenol solution, and undergo ultrasonic treatment to obtain an electrospinning solution; the mass fraction of nano-zinc oxide is 5%, the ultrasonic temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com