Adhesion hinged type segmented prefabricated assembled arch bridge and intelligent construction control method

A segmented prefabrication and articulated technology, which is applied to arch bridges, erection/assembly bridges, bridges, etc., can solve problems such as high process requirements, inaccurate structural alignment control, and uneven distribution of material strength, so as to simplify the construction process and improve construction efficiency. Efficiency and site suitability, and the effect of improving manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

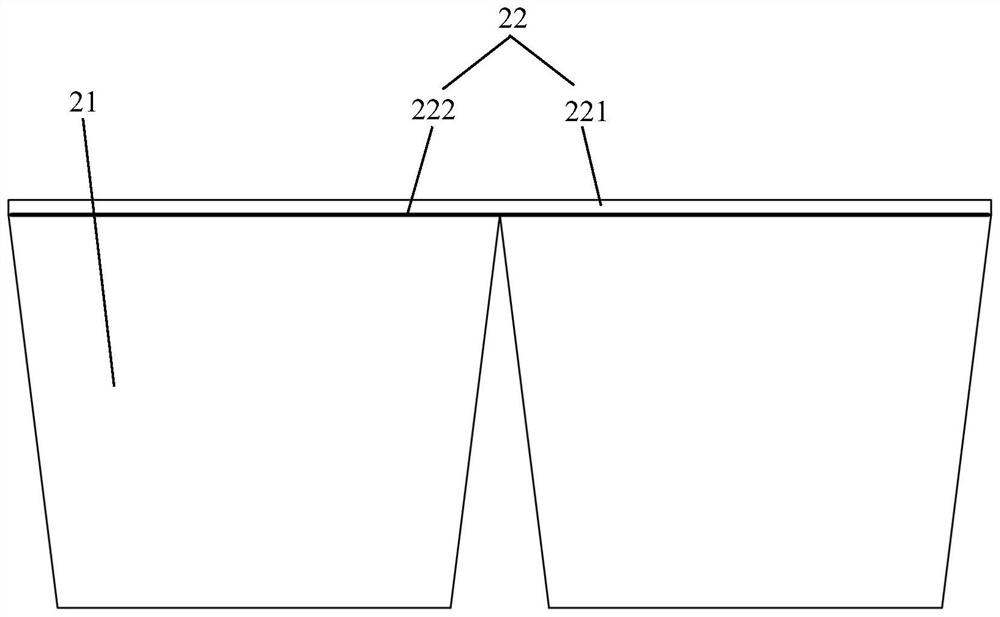

[0055] See attached figure 2 , the reinforcement 222 is a high-performance carbon fiber cloth; the polymer adhesive 221 bonds the high-performance carbon fiber cloth to the top surface of the prefabricated wedge block 21 .

Embodiment 2

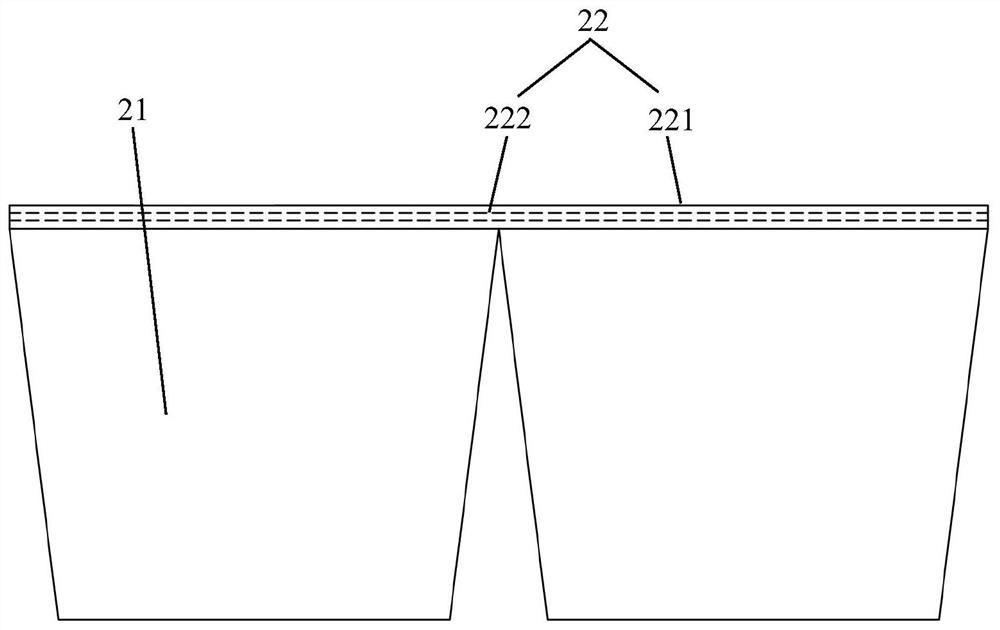

[0057] See attached image 3 , the reinforcement 222 is an FRP stiffening cable, steel cable or steel strand; the polymer adhesive 221 is bonded to the top surface of the prefabricated wedge block 21, and the FRP stiffening cable, steel cable or steel strand is wrapped inside the polymer adhesive 221 .

Embodiment 3

[0059] See attached Figure 5 , the prefabricated wedge-shaped block 21 is a solid concrete structure, and the joint surface of two adjacent prefabricated wedge-shaped blocks 21 is prefabricated with a protruding notch structure 211 that can be plugged and fitted; the protruding notch structure 211 is a raised cross type structure and recessed cross groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com