Preparation method of paper-based insect trapping board barrier layer

A technology of an insect trap and a barrier layer is applied to the barrier layer of a paper-based insect trap and its preparation field. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

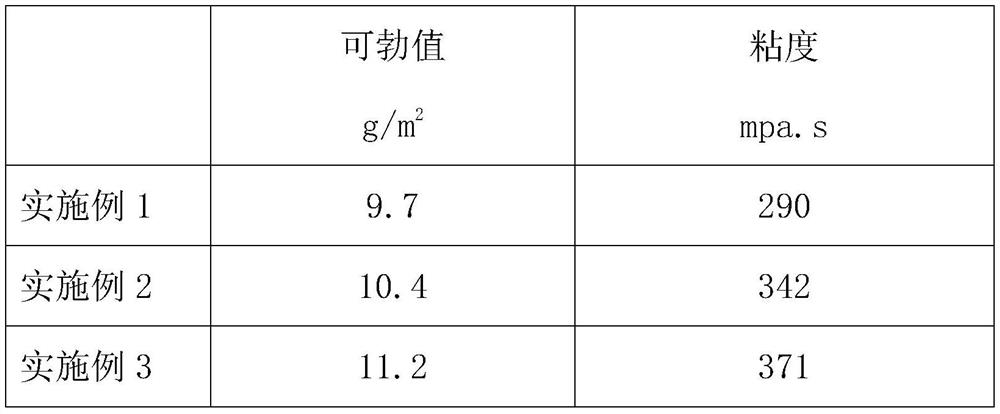

Embodiment 1

[0023] A paper-based insect trap barrier layer and its preparation steps are as follows:

[0024] Step 1: Mix 90 parts of styrene-acrylic latex, 10 parts of styrene-butadiene latex, 5 parts of wax emulsion, and 0.2 parts of defoamer emulsified silicone oil, etc. and mix together mechanically to prepare a composite emulsion. The rotation speed is 300r / min, and the mixing time is 10min.

[0025] Step 2: Add 5 parts of yellow color paste and 1.5 parts of thickener carboxymethyl cellulose, etc. into the composite emulsion prepared in step 1, wherein the rotation speed is preferably 400r / min, and the mixing time is 30min.

[0026] Step 3: Filter the composite emulsion prepared in Step 2, wherein the filter screen is a 325-mesh metal mesh to obtain the barrier layer liquid of the paper-based insect trap.

[0027] Step 4. Use a coating machine to coat the composite emulsion on both sides, wherein the oven temperature is 105°C, and the latex coating amount is 10g / m 2 , to prepare a ...

Embodiment 2

[0029] A paper-based insect trap barrier layer and its preparation steps are as follows:

[0030] Step 1: Mix 50 parts of styrene-acrylic latex, 50 parts of styrene-butadiene latex, 5 parts of wax emulsion, and 0.2 parts of antifoaming agent polyoxypropylene glyceryl ether, etc. and mechanically stir to prepare a composite emulsion, wherein the speed is 300r / min, The mixing time was 10 minutes.

[0031] Step 2: Add 5 parts of yellow color paste and 1 part of thickener guar gum, etc. into the composite emulsion prepared in step 1, wherein the rotation speed is preferably 400r / min, and the mixing time is 30min.

[0032] Step 3: Filter the composite emulsion prepared in Step 2, wherein the filter screen is a 325-mesh metal mesh to obtain the barrier layer liquid of the paper-based insect trap.

[0033] Step 4. Use a coating machine to coat the composite emulsion on both sides, wherein the oven temperature is 105°C, and the latex coating amount is 10g / m 2 , to prepare a waterpro...

Embodiment 3

[0035] A paper-based insect trap barrier layer and its preparation steps are as follows:

[0036] Step 1: Mix 10 parts of styrene-acrylic latex, 90 parts of styrene-butadiene latex, 5 parts of wax emulsion and 0.2 parts of antifoaming agent polydimethylsiloxane, etc. and mechanically stir to prepare a composite emulsion, wherein the rotation speed is 300r / min, the mixing time is 10min.

[0037] Step 2: Add 5 parts of yellow color paste and 2 parts of thickener starch into the composite emulsion prepared in step 1, preferably at a rotation speed of 400r / min, and mixing time of 30 minutes.

[0038] Step 3: Filter the composite emulsion prepared in Step 2, wherein the filter screen is a 325-mesh metal mesh to obtain the barrier layer liquid of the paper-based insect trap.

[0039] Step 4. Use a coating machine to coat the composite emulsion on both sides, wherein the oven temperature is 105°C, and the latex coating amount is 10g / m 2 , to prepare a waterproof paper-based substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com