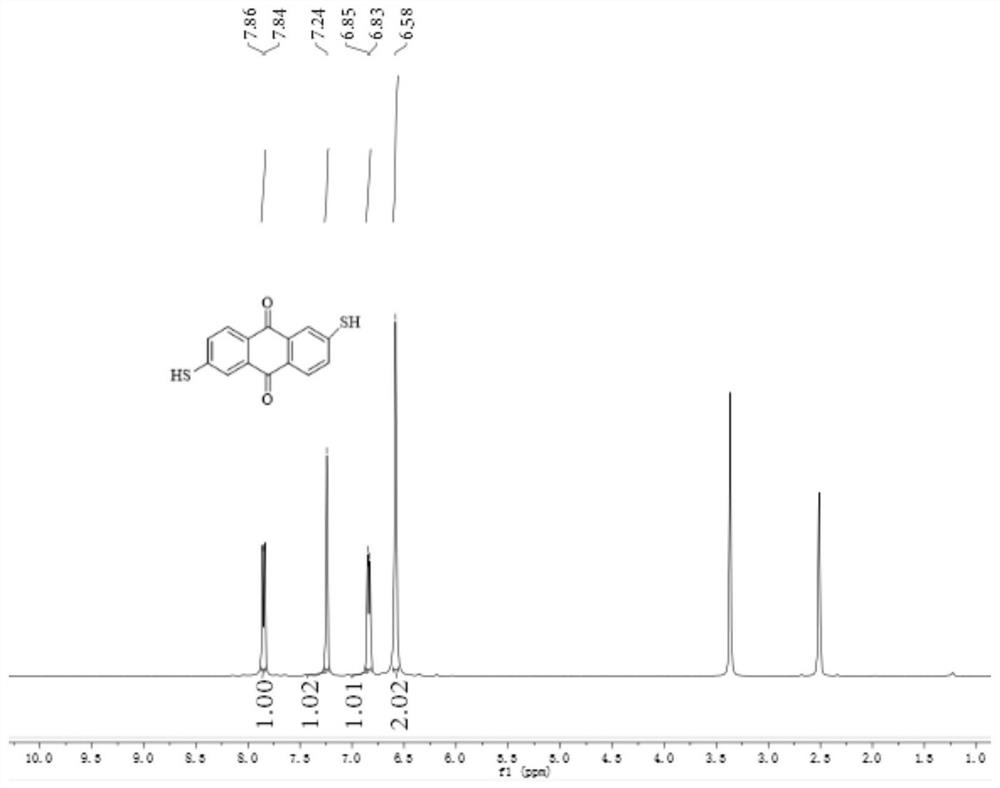

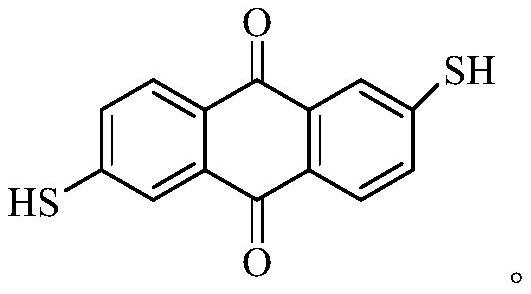

Method for dyeing polypropylene fibers with sulfydryl-containing anthraquinone type disperse dye

A mercapto-anthraquinone type, polypropylene fiber technology, applied in the direction of dyeing, textiles and papermaking, can solve the problems of low dye uptake, poor color fastness, etc., and achieve high dye uptake, good fastness performance, good The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take 1g of mercapto-anthraquinone-type disperse dye, 1g of dispersant NNO, 60g of zirconium beads (0.8mm in diameter), and 10mL of water, and put them into a sand mill for 8 hours of sanding. After the sanding, filter through a fine nylon filter cloth to collect the dye Dilute the dispersion liquid in a 100mL volumetric flask to obtain a dye paste; pipette the dye paste according to the 2% chroma requirement, add a buffer solution of sodium acetate and ammonia water (pH value is 5) at a bath ratio of 1:30, and then transfer Add 1g of polypropylene fabric to be dyed into the dyeing cup, put it into a high-temperature and high-pressure dyeing machine, raise the temperature to 60°C at a rate of 2°C / min, then raise the temperature to 120°C at a rate of 1°C / min, keep it warm for 30 minutes and then drop to At room temperature, take out the dyed cloth swatch. Put the dyed polypropylene fabric into 13mL hydrogen peroxide-ammonia solution (the volume ratio of hydrogen peroxide ...

Embodiment 2

[0040] Take 1g of mercaptoanthraquinone-type disperse dye, 2g of dispersant NNO, 50g of zirconium beads (0.7mm in diameter), and 10mL of water, and put them into a sand mill for 6 hours of sanding. After the sanding, filter through a fine nylon filter cloth to collect the dye The dispersion liquid was fixed in a 100mL volumetric flask to obtain the dye paste; the dye paste was pipetted according to the 1% chroma requirement, and the buffer solution of sodium acetate and ammonia water (pH value was 5) was added according to the bath ratio of 1:20, and then transferred Add 0.5g of polypropylene fabric to be dyed into the dyeing cup, put it into a high-temperature and high-pressure dyeing machine, raise the temperature to 65°C at a rate of 2°C / min, then raise the temperature to 110°C at a rate of 1°C / min, and keep it warm for 30 minutes Cool down to room temperature and take out the dyed swatch. Put the dyed polypropylene fabric into 7mL hydrogen peroxide-ammonia solution (the vo...

Embodiment 3

[0043] Take 1g of mercaptoanthraquinone-type disperse dye, 2g of dispersant NNO, 50g of zirconium beads (0.7mm in diameter), and 30mL of water, and put them into a sand mill for 6 hours of sanding. After the sanding, filter through a fine nylon filter cloth to collect the dye The dispersion liquid was fixed in a 100mL volumetric flask to obtain a dye paste; 2% chroma required to pipette the dye paste, add a buffer solution of sodium acetate and ammonia water (pH value was 6) at a bath ratio of 1:40, and then transfer to Add 1g of polypropylene fabric to be dyed into the dyeing cup, put it into a high-temperature and high-pressure dyeing machine, raise the temperature to 70°C at a rate of 2°C / min, then raise the temperature to 130°C at a rate of 1°C / min, keep it warm for 30 minutes, and then cool it down to room temperature , take out the dyed cloth sample. Put the dyed polypropylene fabric into 13mL hydrogen peroxide-ammonia solution (the volume ratio of hydrogen peroxide and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com