PC/ABS composite material and preparation method thereof

A technology of composite materials and raw materials, which is applied in the field of antibacterial PC/ABS composite materials and its preparation, can solve the problems of PC/ABS alloy materials such as poor weather resistance, toughness to be improved, and poor wear resistance, so as to achieve excellent dispersion performance and enhance dazzling colors Metal/pearl texture, effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

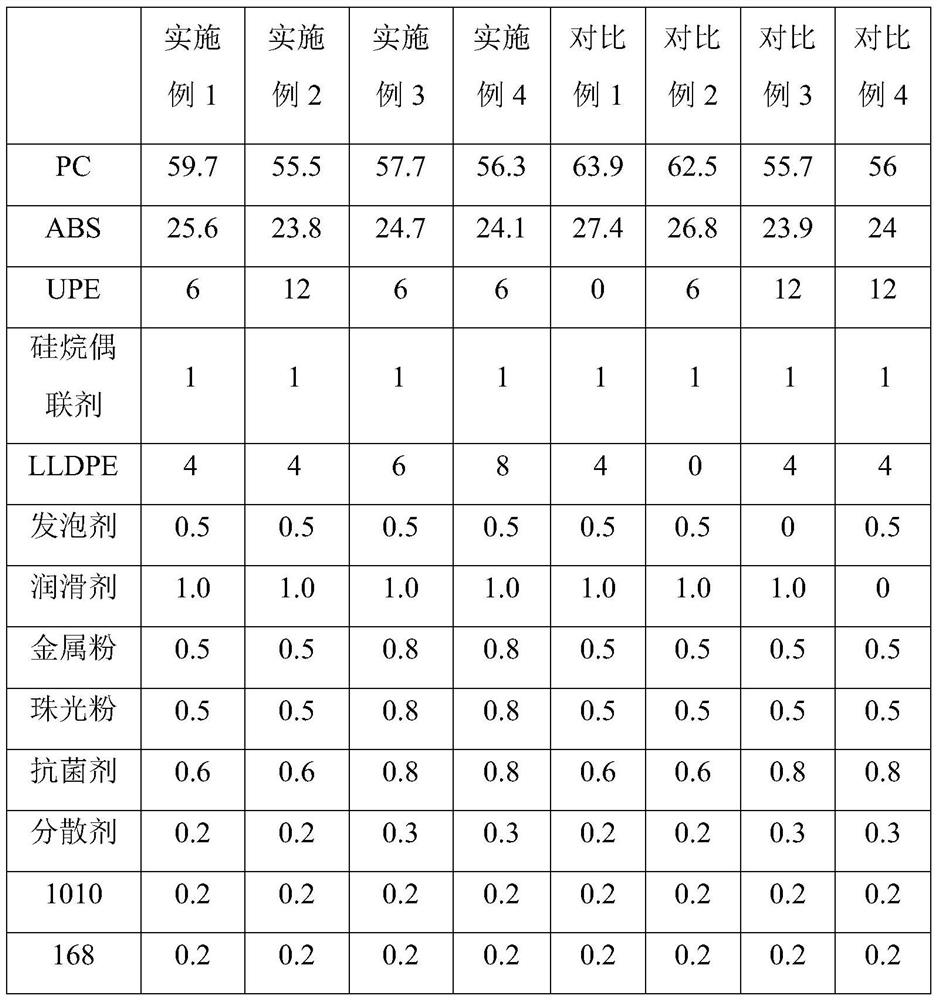

[0033] An antibacterial PC / ABS alloy material with wear-resistant and weather-resistant colorful metal effect, which includes the following raw materials in parts by weight: 59.7 parts of PC, 25.6 parts of ABS, 6 parts of toughening agent, 1 part of silane coupling agent, LLDPE 4 parts, compatibilizer 0.5 parts, lubricant 1 part, metal powder 0.3 parts; pearl powder 0.3 parts; antibacterial agent 0.6 parts; dispersant 0.2 parts; main antioxidant 1010 0.2 parts, Secondary antioxidant 168 is 0.2 parts.

[0034] The preparation method of the wear-resistant and weather-resistant colorful metal effect PC / ABS alloy material comprises the following steps:

[0035] Dry PC and ABS, PC is dried at 90°C for 4 hours, ABS is at 80°C, and the drying time is 3 hours;

[0036] Add the antibacterial agent and dispersant to the vibrating powder machine according to the ratio for pre-mixing, the mixing time is 30-60min, and the speed of the stirring paddle is 100-400rpm;

[0037] (3) Weigh the...

Embodiment 2

[0041] Raw material ratio is shown in Table 1, and its preparation method is identical with embodiment 1.

Embodiment 3

[0043] Raw material ratio is shown in Table 1, and its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com