Control method for solving blank stagnation of Dalnell slab continuous casting machine

The technology of a slab continuous casting machine and a control method is applied in the field of Danieli slab continuous casting machine sluggish control, and can solve problems such as poor working conditions, reduced casting slab quality, and hidden dangers in production safety, so as to reduce Cracks on the surface of the billet, the effect of improving the surface quality and ensuring the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

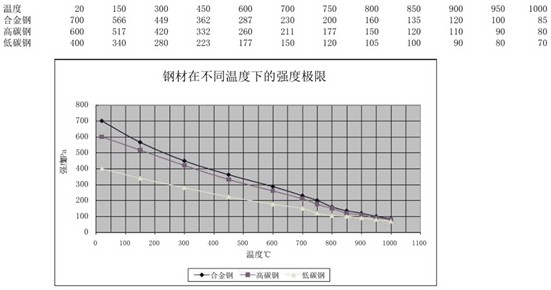

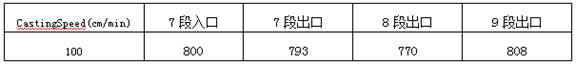

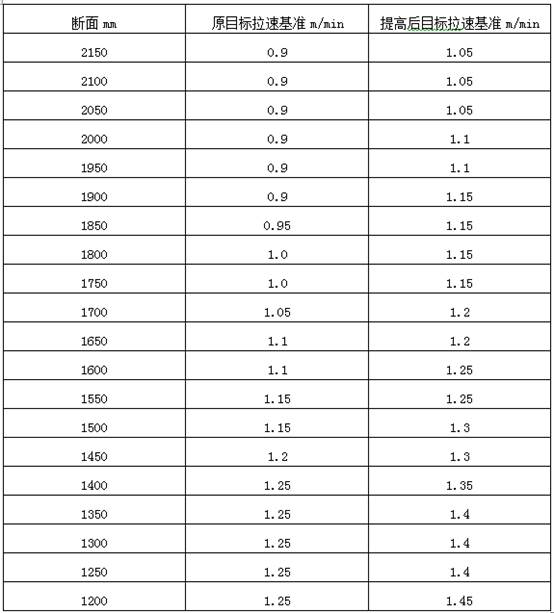

[0036] Embodiment 1: Production of No. 7 (MC-HSLA) steel grade 1800-2000mm, casting speed 0.95-1.15m / min, in order to ensure the accuracy of the cooling surface temperature of the slab after the adjustment of the secondary cooling water coefficient. Implementation plan: ① Check the mold of the casting machine to the 8th section one by one before production. There is no obvious water leakage in each equipment, and the spraying state can play a uniform cooling effect on the billet; ② Strictly control the production rhythm to ensure constant casting speed ; ④ The whole process control ensures that the superheat of the continuous casting tundish is between 15 and 25 ℃. The temperature of the cooling surface of the slab was increased, the straightening yield strength of the slab was effectively reduced, and the walking resistance of the slab was reduced. There was no stagnation of the slab in the two pouring times.

[0037]

Embodiment 2

[0038] Example 2: Production of No. 11 (PIPE) steel grade 1200-1550mm, casting speed 1.25-1.45m / min, in order to ensure the accuracy of the cooling surface temperature of the slab after the adjustment of the secondary cooling water coefficient. Implementation plan: ① Check the mold of the casting machine to the 8th section one by one before production. There is no obvious water leakage in each equipment, and the spraying state can play a uniform cooling effect on the billet; ② Strictly control the production rhythm to ensure constant casting speed ; ④ The whole process control ensures that the superheat of the continuous casting tundish is between 15 and 25 ℃. The temperature of the cooling surface of the slab was increased, the straightening yield strength of the slab was effectively reduced, and the walking resistance of the slab was reduced. There was no stagnation of the slab in the three pouring times.

[0039]

Embodiment 3

[0040] Embodiment 3: No. 6 (PER-HSLA) steel grade was produced, and the casting speed was 1.1-1.25m / min, in order to ensure the accuracy of the cooling surface temperature of the slab after the adjustment of the secondary cooling water coefficient. Implementation plan: ① Check the mold of the casting machine to the 8th section one by one before production. There is no obvious water leakage in each equipment, and the spraying state can play a uniform cooling effect on the billet; ② Strictly control the production rhythm to ensure constant casting speed ; ④ The whole process control ensures that the superheat of the continuous casting tundish is between 15 and 25 ℃. The temperature of the cooling surface of the slab was increased, the straightening yield strength of the slab was effectively reduced, and the walking resistance of the slab was reduced. There was no stagnation of the slab in the three pouring times.

[0041]

[0042] The invention fully exerts the performance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com