Atomizing agent containing alkylated glycerol as well as preparation method and application of atomizing agent

A technology of alkylated glycerin and atomizing agent, applied in the application and preparation of tobacco, tobacco, etc., can solve the problems of production difficulties, irritation, troublesome operation, etc., to improve the quality of suction, improve the dryness of the throat, and the formula is simple effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

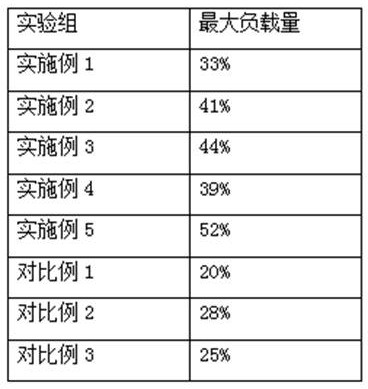

Examples

Embodiment 1

[0033] An aerosol containing alkylated glycerin, prepared by the following steps:

[0034] According to parts by mass, 10 parts of glycerin, 20 parts of glycerol ether, 5 parts of ethyl pyruvate, 0.2 parts of mannitol monooleate, and 0.2 parts of polyethylene glycol 600 monooleate were prepared.

[0035] S1. Add mannitol monooleate to ethyl pyruvate at a speed of 800r / min, mix well and heat to 80°C. Then slowly add glycerin into the mixing system at a speed of 400r / min. After the addition of glycerin, first magnetically stir at 800r / min for 3min, and then sonicate for 8min at a frequency of resting for 3s after working for 3s, to obtain coating body 1.

[0036] S2. At a speed of 400r / min, add the coating body 1 to glycerol ether, and add polyethylene glycol 600 monooleate. After the addition, first stir magnetically at a speed of 800r / min for 3min, and then After working for 3s, rest for 3s and sonicate for 8min at a frequency to obtain an aerosol.

[0037] Spray the atomizin...

Embodiment 2

[0039] This example is basically the same as Example 1, except that it also includes 5 parts of carboxymethyl chitosan and 0.3 part of 40 U / ml pyruvate decarboxylase enzyme solution.

[0040] In step S2, at a rotational speed of 100 r / min, the glycerol ether, carboxymethyl chitosan and pyruvate decarboxylase are uniformly mixed to obtain a mixture.

[0041] Then at a rotating speed of 400r / min, add the coating body 1 to the mixture, and add polyethylene glycol 600 monooleate. After 3 s, rest 3 s and sonicate for 8 min to obtain an aerosol.

Embodiment 3

[0043] This example is basically the same as Example 1, except that it also includes 5 parts of carboxymethyl chitosan and 0.3 part of 40 U / ml pyruvate decarboxylase enzyme solution.

[0044] In step S2, at a rotational speed of 400r / min, the coating body 1 was added to glycerol ether, and polyethylene glycol 600 monooleate was added. After the addition was completed, magnetic stirring was first performed at a rotational speed of 800r / min for 3 minutes. Then, after working for 3s, the frequency of resting for 3s was ultrasonicated for 8min to obtain coating body 2 .

[0045] Under the rotating speed of 100r / min, the carboxymethyl chitosan and the pyruvate decarboxylase are evenly mixed to obtain the immobilized enzyme.

[0046] At a rotational speed of 100 r / min, the coated body 2 and the immobilized enzyme were evenly mixed to obtain an aerosol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com