Silver tin oxide indium oxide electrical contact and production device thereof

A technology of silver tin oxide and production equipment, applied in the direction of contacts, circuits, electric switches, etc., can solve the problems of unfavorable rapid production of electrical contacts, unfavorable use of electrical contacts, and rise in resistance, so as to save manpower and material resources and improve utilization Efficiency, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

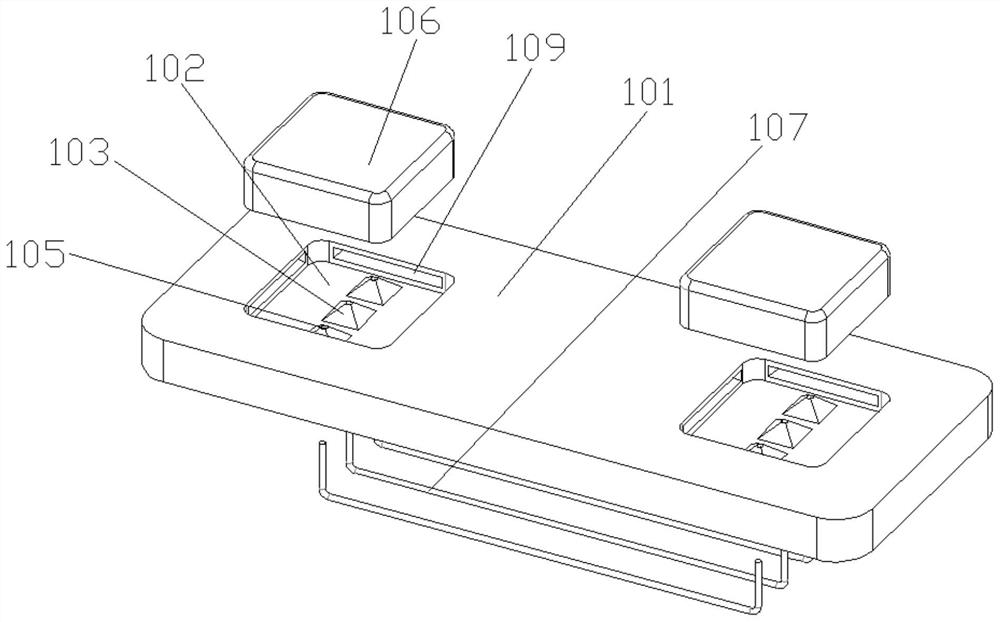

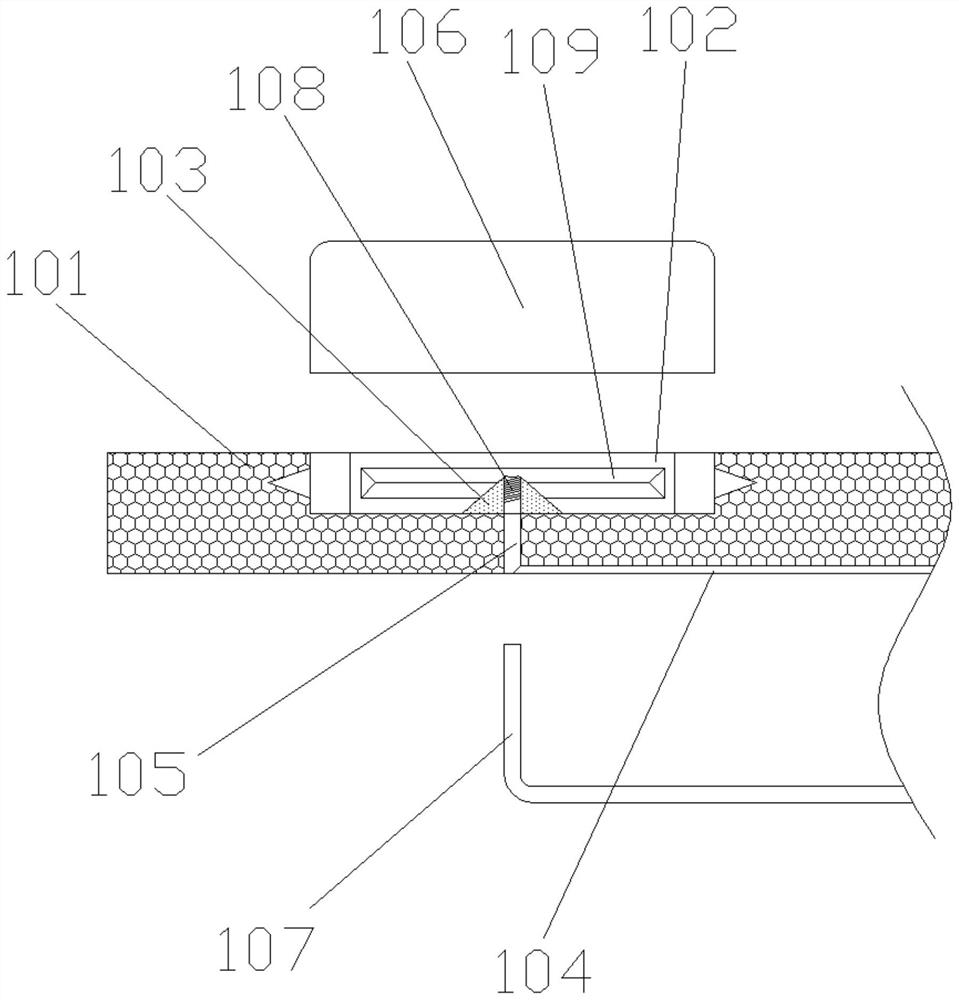

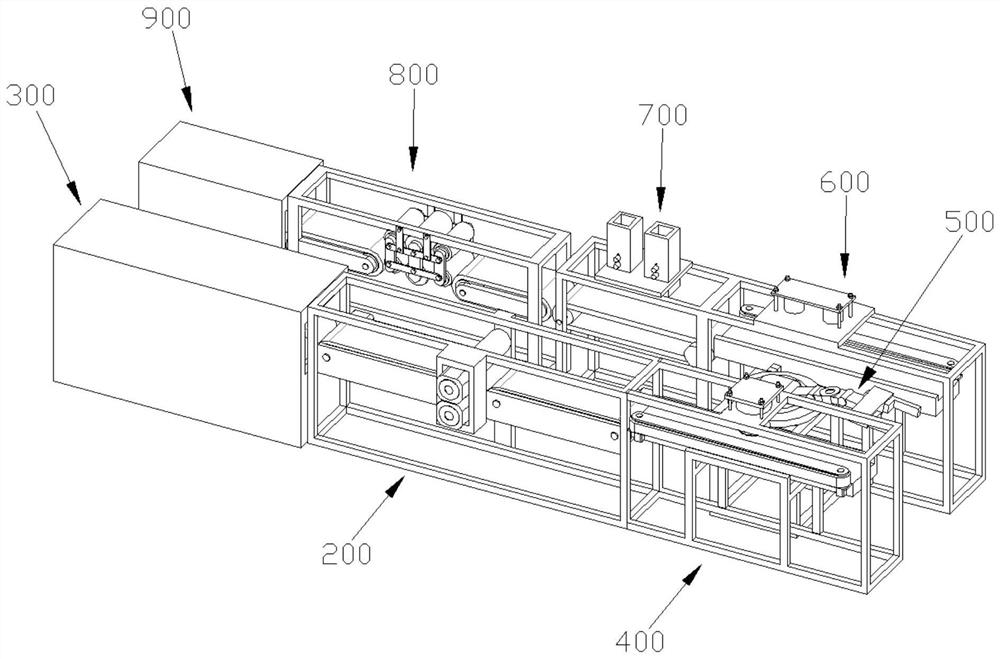

[0044] see Figure 1 to Figure 14 , in an embodiment of the present invention, a production device for silver tin oxide indium oxide electrical contacts, including a first pressing device 200, a heating device 300, a first grinding device 400, a material turning device 500, a second grinding device 600, The discharging device 700, the second pressing device 800 and the surface treatment device 900, the first pressing device 200 and the heating device 300 are arranged in cooperation, the first grinding device 400 is arranged in cooperation with the first pressing device 200, the material turning device 500 is arranged in conjunction with the first The grinding device 400 and the second grinding device 600 are arranged in cooperation, the second grinding device 600 is arranged in cooperation with the discharging device 700, the second pressing device 800 is arranged in cooperation with the discharging device 700, and the surface treatment device 900 is arranged in cooperation wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com