Long-life high-carbon bearing steel pipe and preparation method and application thereof

A high-carbon bearing and long-life technology, applied in the field of bearing steel, can solve problems such as low life, high inner and outer rings of bearings, and inability to manufacture fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides a preparation method of the long-life high-carbon bearing steel pipe described in the above scheme, comprising the following steps:

[0038] Corresponding to the chemical composition of the long-life high-carbon bearing steel pipe, smelting each preparation raw material to obtain an ingot;

[0039] Homogenizing the cast ingot, and then performing hot forging or hot rolling to obtain bearing steel rods;

[0040] rolling the bearing steel bar through a pipe to obtain an intermediate pipe;

[0041] The intermediate pipe is subjected to spheroidizing annealing, quenching and tempering in sequence to obtain a long-life high-carbon bearing steel pipe.

[0042] According to the chemical composition of the long-life high-carbon bearing steel pipe, the present invention smelts each preparation raw material to obtain an ingot. The present invention has no special requirements on the smelting process, and the smelting process well known in the art ...

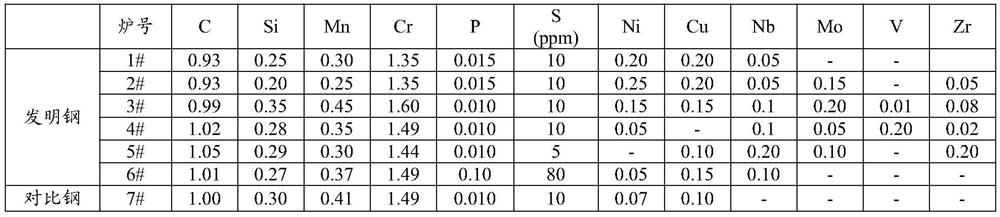

Embodiment 1

[0057] According to the composition of furnace number 1# in Table 1, each preparation raw material is smelted, adopts vacuum induction furnace to smelt, casting ingot shape is the round ingot of 50kg, and ingot diameter is about 120mm;

[0058] Heating the ingot at 1200°C, holding it for 6 hours for homogenization treatment, and then forging the billet, the forging temperature range is 1220°C, water cooling after forging, and finally forging into a bearing steel bar with a diameter of 50mm;

[0059] Heat the bearing steel bar with a diameter of 50mm to 1040-1050°C and keep it warm for 2 hours; carry out rough rolling on the heated bar to pass through the tube, and control the starting rolling temperature at 1000°C; then perform finish rolling and control the final rolling The temperature is 930°C, and after rolling, it is quickly water-cooled to 600°C and then air-cooled to room temperature to obtain intermediate pipes;

[0060] The intermediate pipe is subjected to spheroidiz...

Embodiment 2~6

[0064] The long-life high-carbon bearing steel was prepared with reference to the conditions of Example 1, the only difference being the composition of the high-carbon bearing steel, see Table 1 for heat numbers 2# to 6# for specific composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com