Preparation method of high-strength flexible wood film

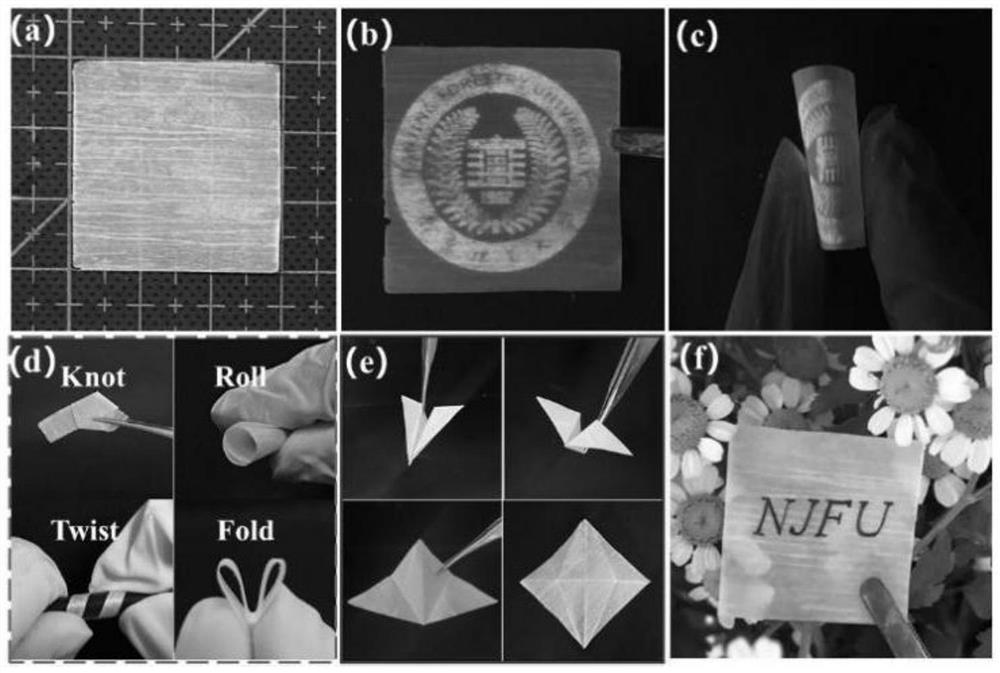

A high-strength, wood-based technology, applied in wood processing equipment, manufacturing tools, etc., can solve problems such as insufficient mechanical properties, high complexity of nano-processing, and high energy consumption, and achieve excellent mechanical strength and expand high-value utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The following are the specific steps of the preparation method of the high-strength flexible water-resistant wood membrane of the present invention:

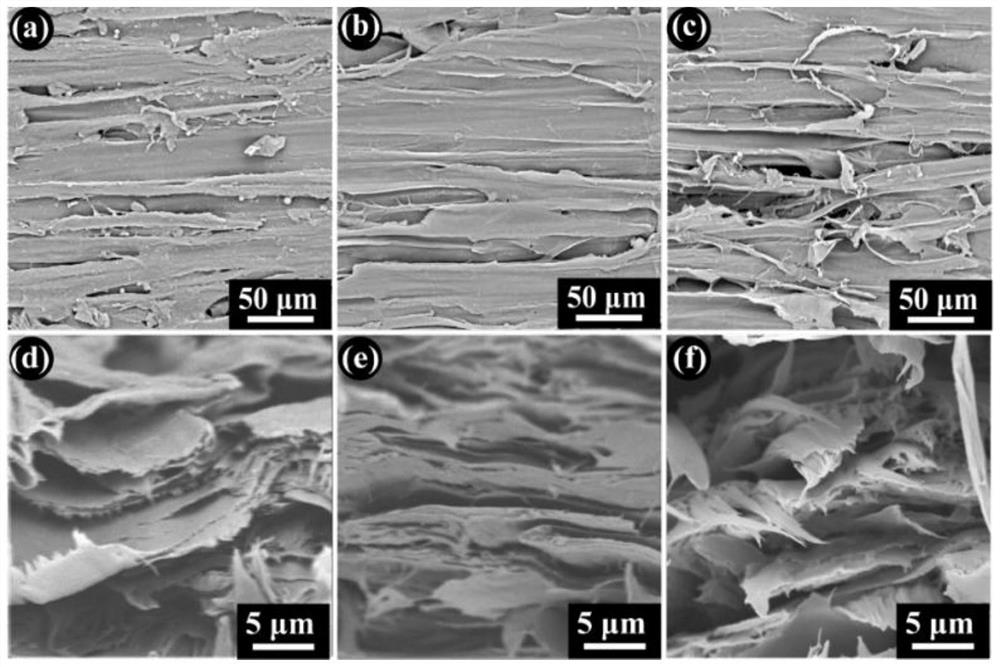

[0034] (1) Dematrix treatment: 10 pieces of longitudinally cut balsa wood chips (density: 0.14g / cm 3 -0.19g / cm 3 ) is placed in 200ml of 1-2wt% sodium chlorite solution, acetic acid is added dropwise to adjust the pH value to 4.6, and the balsa is delignified by heating at 100° C. for 2 hours. After the reaction, the chips were rinsed with distilled water until neutral. Then place the treated wood chip sample in a sodium hydroxide solution with a mass fraction of 6-15 wt%, and treat it for 2 hours at a temperature of 25-90°C to remove hemicellulose from the balsa wood. Wood chips are washed to neutral to obtain dematrix treated wood.

[0035] (2) TEMPO treatment: place the dematrixed wood obtained in the above steps in 100ml, 6wt% sodium hypochlorite aqueous solution, add 16mg TEMPO, 100mg sodium bromide, and stir even...

Embodiment 1

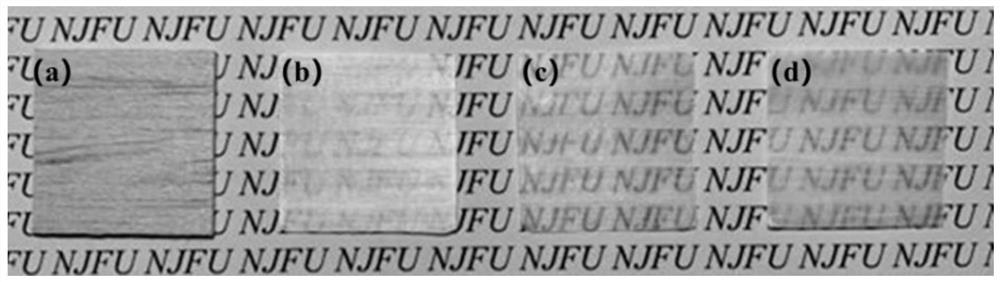

[0041] Example 1 (Destromed Wood Membrane) - This example was without TEMPO treatment and without acetylation treatment.

[0042] (1) Take 10 pieces of longitudinally cut balsa wood chips (density: 0.14g / cm 3 -0.19g / cm 3 ) placed in 200ml of 2wt% sodium chlorite solution, acetic acid was added dropwise to adjust the pH to 4.6, and heated at 100°C for 2 hours to delignify the balsa wood. After the reaction, the chips were rinsed with distilled water until neutral.

[0043] (2) Afterwards, place the processed wood chip sample in a sodium hydroxide solution with a mass fraction of 6 wt%, and heat it at 90°C for 2 hours to remove hemicellulose from the balsa wood. Rinse to neutral to obtain destratum treated wood.

[0044] (3) Cover both sides of the dematrix-treated wood obtained in the above steps with filter paper, stainless steel mesh, and glass plates in order to flatten them, place them in a 60°C oven for drying and hot pressing for 48 hours, and perform drying and densif...

Embodiment 2

[0046] Example 2 (destratum / TEMPO treated wood film) was not treated with acetylation.

[0047] (1) Take 10 pieces of longitudinally cut balsa wood chips (density: 0.14g / cm 3 -0.19g / cm 3 ) placed in 200ml of 2wt% sodium chlorite solution, acetic acid was added dropwise to adjust the pH to 4.6, and heated at 100°C for 2 hours to delignify the balsa wood. After the reaction, the chips were rinsed with distilled water until neutral.

[0048] (2) Afterwards, place the processed wood chip sample in a sodium hydroxide solution with a mass fraction of 6 wt%, and heat it at 90°C for 2 hours to remove hemicellulose from the balsa wood. Rinse to neutral to obtain destratum treated wood.

[0049] (3) Place the de-strommed wood obtained in the above steps in 100ml, 6wt% sodium hypochlorite aqueous solution, then add 16mgTEMPO, 100mg sodium bromide, stir evenly, and react at 30°C for 4 hours. The buffer used during the reaction is a mixed phosphate solution with a pH of 6.86 and a bora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com