Manufacturing method of high-strength and high-toughness plate coil for high-precision spiral submerged arc welding pipe

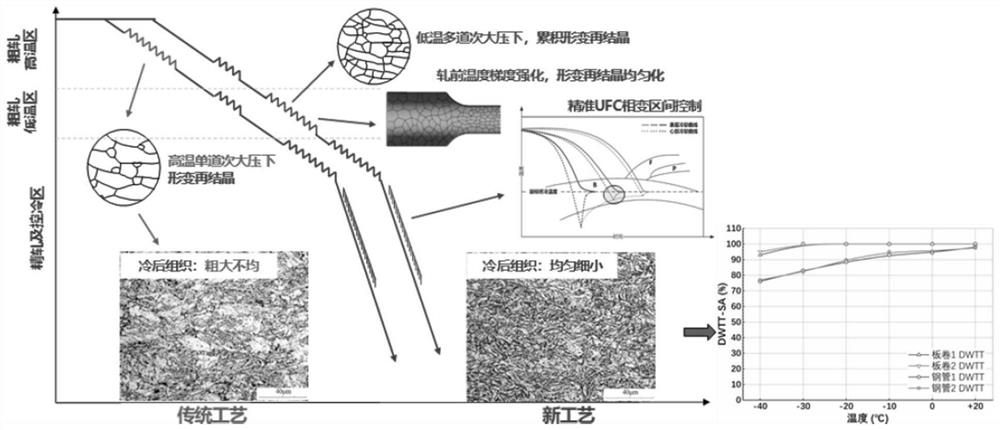

A manufacturing method and submerged arc welding technology, applied in manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of low compression ratio structure refinement of thick plates, deviation of coil shape control, and unstable temperature field. , to achieve the effect of improving low temperature toughness, ensuring molding accuracy, and small and uniform organizational units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

[0031] Example parameters of each embodiment of the present invention is as follows:

[0032]

[0033] Inspection of the properties Example embodiments of the invention as follows:

[0034]

[0035]

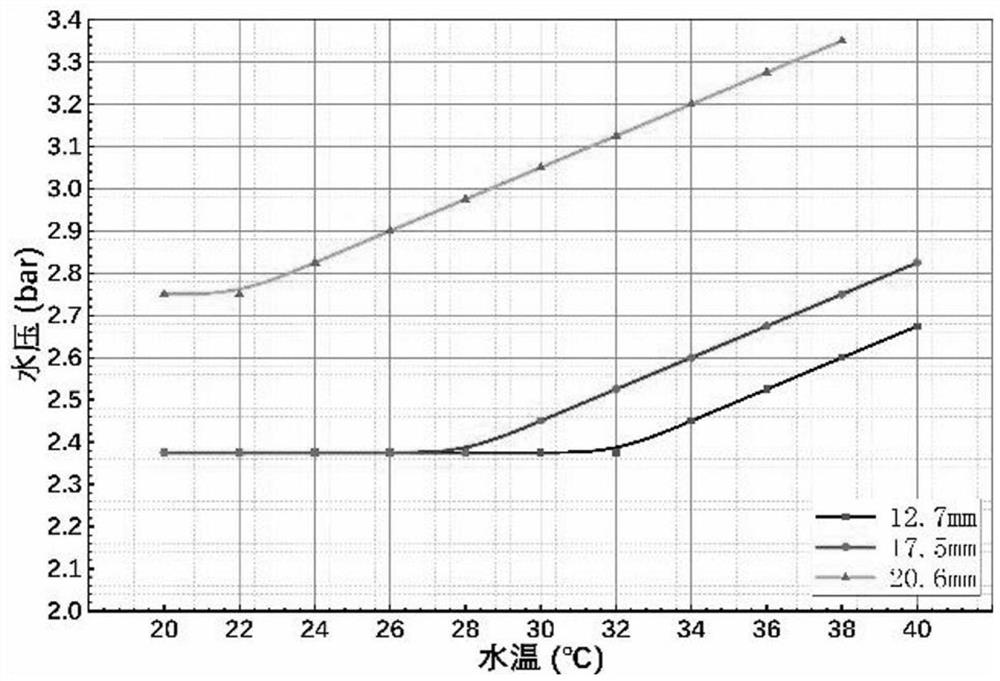

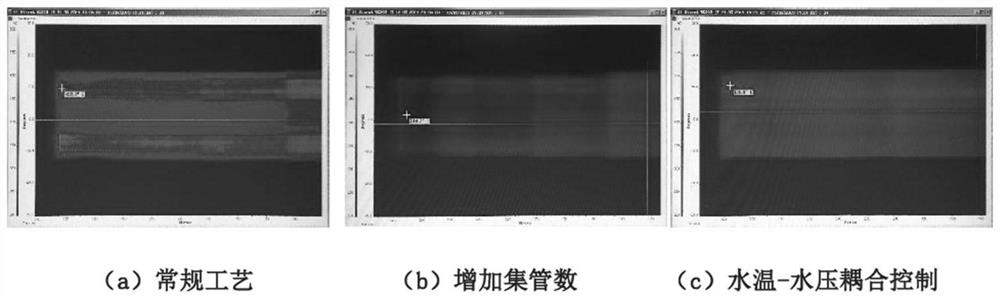

[0036] Example 8 by the physical and chemical properties of the integrated data shows that Example 8 group overall performance can meet the technical requirements of X70 grade pipeline, has good strength and toughness, by rapid cooling and coiling UFC entire board width is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com