Reactor provided with spiral pipe and application thereof

A technology of spiral tube and reactor, applied in the field of catalysis, to achieve the effects of easy large-scale production and application, control of hot spot temperature, and reduction of overheating phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

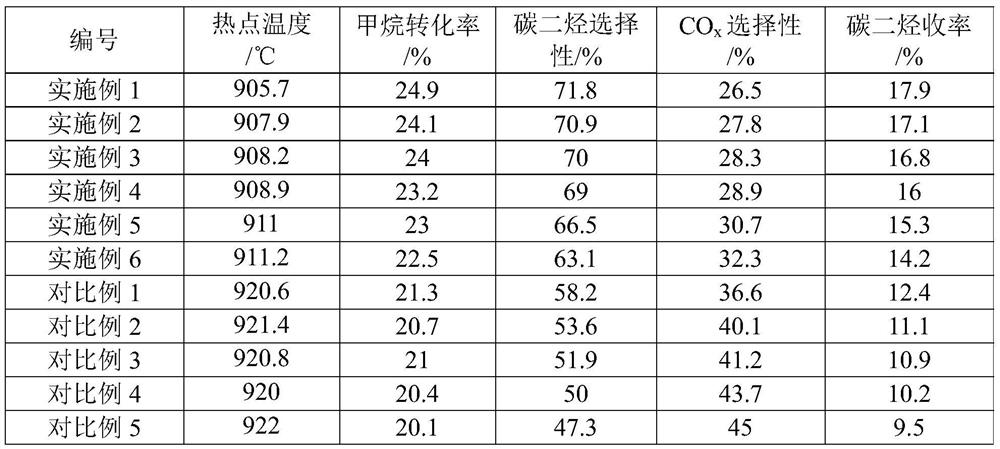

Examples

preparation example 1

[0053] The preparation method of the catalyst without additives: add the precursor of the active component into 50°C, 25g deionized water, add the carrier, stir for 2 hours, dry at 120°C for 24 hours, and then roast at 750°C for 6 hours to obtain the catalyst.

preparation example 2

[0055] The preparation method of the catalyst with the auxiliary agent: add the precursor of the active component into 25g deionized water at 50°C, add the carrier, stir for 2 hours, and dry at 120°C for 24 hours to obtain solid A; then the precursor of the auxiliary agent Dissolve in 25 g of deionized water at 50°C, add solid A, stir for 2 hours, dry at 120°C for 24 hours, and then roast at 750°C for 6 hours to obtain the catalyst used in the examples.

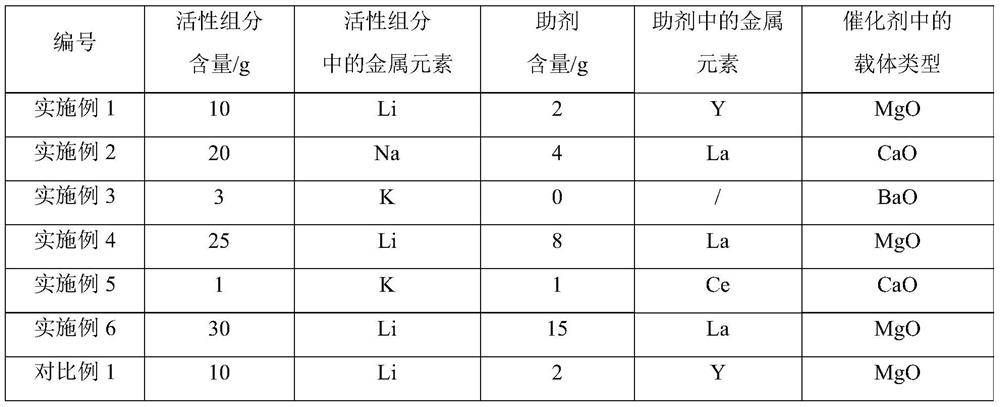

[0056] The precursor of the active component and the precursor of the auxiliary agent in the preparation example all refer to nitrate, and the usage amount of each component makes the content of the active ingredient and the auxiliary agent in the catalyst as shown in table 1:

[0057] Table 1

[0058]

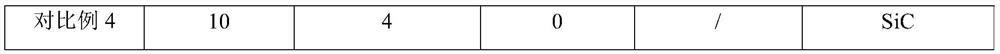

[0059]

[0060] Note: the content of each component in the catalyst is based on 100g carrier;

[0061] " / " indicates that there is no additive in the catalyst.

Embodiment 1

[0063] The reactor is a quartz tube with an inner diameter of 10mm and a length of 530mm. The total catalyst loading is 1g, and the length of the catalyst section reaches 10mm. A spiral tube with an outer diameter of 2mm is inserted from the top of the reactor, and the inner diameter of the spiral tube is 1mm. , the length of the helical tube is 20cm, the distance between the outer wall of the helical tube and the outer wall of the reaction chamber is 0mm, the pitch of the helical tube is 3mm, the distance between the gas outlet of the helical tube and the cross-section of the downstream end of the catalyst section is 8mm, and nitrogen flows from the helical tube The air inlet of the nitrogen gas enters and is discharged from the gas outlet of the spiral tube. The nitrogen temperature is 30°C and the nitrogen flow rate is 200mL / min. The reaction pressure is the pressure generated by the raw material itself, that is, 0.011MPa, the reaction temperature is 750°C, the volume ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com