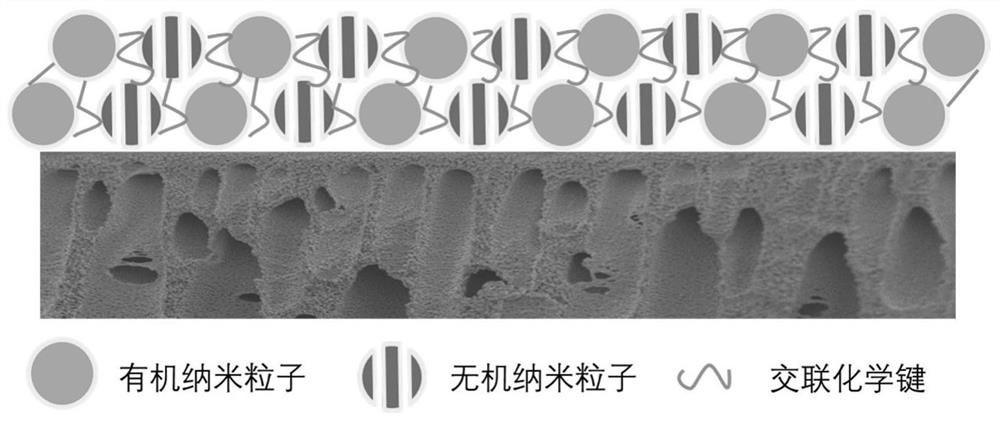

Charged composite nanofiltration membrane based on organic-inorganic nanoparticles and preparation method thereof

A technology of inorganic nanoparticles and composite nanofiltration membranes, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as poor structural stability, single/multivalent ion selectivity and insufficient permeation flux of nanofiltration membranes , achieve good pressure resistance, excellent long-term use stability, and simplify the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Add 6g of methyl methacrylate, 5g of methacryloxyethyltrimethylammonium chloride, and 2g of hydroxyethyl methacrylate into 85g of deionized water and mix well, then add 0.15g of For ammonium persulfate, nitrogen gas was introduced into the reaction system for 30 minutes to remove the air in the reaction system, and then the system was reacted at 75° C. for 6 hours, and the whole process was carried out under mechanical stirring at 300 r / min. After the reaction is over, the reaction container is quickly transferred to cold water for cooling to terminate the reaction and obtain cationic amphiphilic polymer nanoparticles.

[0050] Add 10g of ethyl orthosilicate, 20g of ethanol, 5g of water, and 1g of triethylamine into a three-necked flask and mix evenly, react at 60°C for 2 hours, and then gradually add 10g of quaternized ammonium-modified aminopropyl tri The mixture of ethoxy silicon, after which the reaction continued to react at 60°C for 4h, the whole reaction process ...

Embodiment 2

[0060] Add 8g of 1,2-difluoroethylene, 8g of trimethylallyl ammonium chloride and 4g of hydroxyethylacrylamide into 80g of water, mix well, then add 0.15g of ammonium persulfate, and blow nitrogen into the reaction device for 30 minutes The air was kept at a mechanical stirring rate of 300r / min, and the reaction system was reacted at 75°C for 6h. After the reaction, the reaction device was quickly transferred to an ice-water bath to cool down, and the reaction was finalized to obtain cationic amphiphilic polymer nanoparticles.

[0061]Add 10g of methyl orthosilicate, 20g of ethanol, 5g of water, and 1g of hydrogen chloride into a three-necked flask and mix evenly, and react at 60°C for 2 hours, then gradually add 10g of aminopropyltrimethoxysilicon and 10g of quaternized ammonium The mixture of modified aminopropyl trimethoxy silicon, then the reaction continued at 60°C for 4h, the whole reaction process was carried out under the mechanical stirring of 300r / min, after the react...

Embodiment 3

[0071] Add 8g of acrylonitrile, 8g of propylenesulfonic acid, and 4g of methylolacrylamide into 80g of water, mix evenly, add 0.2g of ammonium persulfate, pass nitrogen into the device for 30 minutes to remove the air in the reaction device, and maintain mechanical stirring The speed was 300r / min, and the reaction system was reacted at 75°C for 6h. After the reaction, the system was quickly transferred to a water bath and cooled to room temperature to terminate the reaction, or anionic amphiphilic polymer nanoparticles.

[0072] Put 10g of butyl orthosilicate, 20g of ethanol, 5g of water, and 1g of ammonia into a three-necked flask and mix evenly, react at 60°C for 2 hours, and then gradually add 20g of carboxylated modified aminopropyl triethoxy to the reaction system The mixture of silicon, after which the reaction continued to react at 60°C for 4h, the whole reaction process was carried out under the mechanical stirring of 300r / min, after the reaction was completed, it was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com