Silicon-carbon negative electrode material with artificial SEI film and preparation method and application of silicon-carbon negative electrode material

A negative electrode material, silicon carbon technology, applied in carbon preparation/purification, negative electrode, battery electrode, etc., can solve problems such as poor thermal stability of storage, improve rate performance, improve stability, and reduce the risk of lithium precipitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

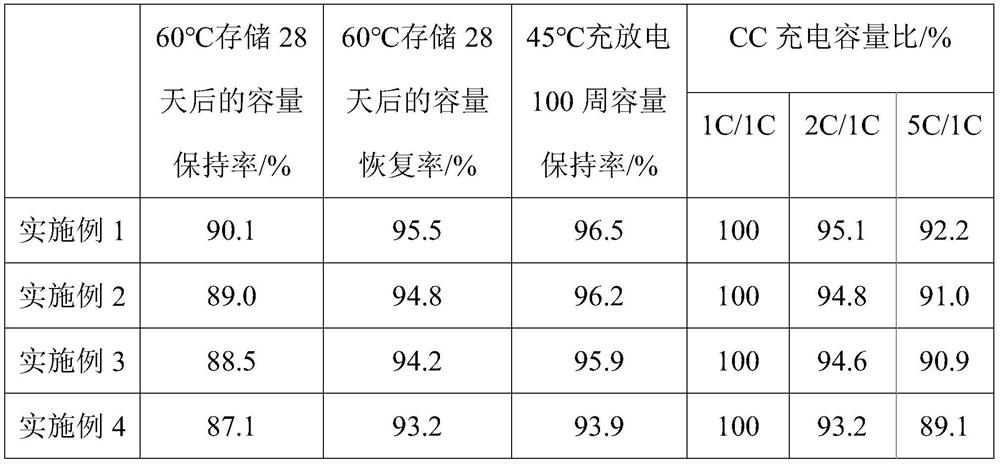

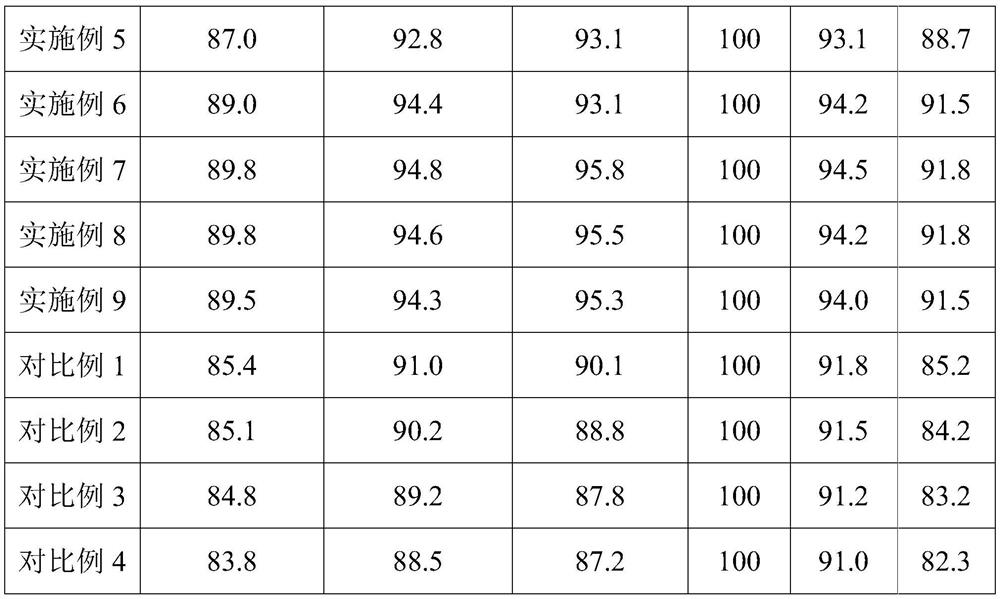

Examples

Embodiment 1

[0070] This embodiment provides a method for preparing a silicon-carbon negative electrode material with an artificial SEI film, the preparation method comprising the following steps:

[0071] (1) Under the condition of helium, ball mill and mix silicon powder, asphalt and N-methylpyrrolidone for 1.5h to obtain nano-silicon slurry;

[0072] Described silicon powder and asphalt mass ratio are 3:1, and the particle diameter D of described silicon powder 50 8μm;

[0073] The nano-silicon slurry, natural graphite and deionized water were stirred and mixed for 3 hours, and spray-dried to obtain a mixture;

[0074] The mass ratio of described nano-silicon slurry and natural graphite is 1:5, and the particle diameter D of described natural graphite 50 20μm;

[0075] (2) Under helium, roast the mixture described in step (1) for 4.5 hours at 750°C and break it to obtain particle size D 50 12.5μm silicon carbon anode material;

[0076] (3) Perfluoromethyl vinyl ether, maleic anhydr...

Embodiment 2

[0082] This embodiment provides a method for preparing a silicon-carbon negative electrode material with an artificial SEI film, the preparation method comprising the following steps:

[0083] (1) Under the condition of argon, ball mill and mix silicon powder, glucose and tetrahydrofuran for 1 hour to obtain nano-silicon slurry;

[0084] Described silicon powder and glucose mass ratio are 4:1, and the particle diameter D of described silicon powder 50 10μm;

[0085]The nano-silicon slurry, natural graphite and deionized water were stirred and mixed for 2 hours, and spray-dried to obtain a mixture;

[0086] The mass ratio of described nano-silicon slurry and natural graphite is 1:8, and the particle diameter D of described natural graphite 50 10μm;

[0087] (2) Under helium, roast the mixture described in step (1) at 650°C for 5 hours, and break it to obtain particle size D 50 10μm silicon carbon anode material;

[0088] (3) Perfluoromethyl vinyl ether, maleic anhydride an...

Embodiment 3

[0094] This embodiment provides a method for preparing a silicon-carbon negative electrode material with an artificial SEI film, the preparation method comprising the following steps:

[0095] (1) Under the condition of argon, ball mill and mix silicon powder, sucrose and toluene for 2 hours to obtain nano-silicon slurry;

[0096] Described silicon powder and sucrose mass ratio are 2:1, and the particle diameter D of described silicon powder 50 5 μm;

[0097] The nano-silicon slurry, natural graphite and deionized water were stirred and mixed for 4 hours, and spray-dried to obtain a mixture;

[0098] The mass ratio of described nano-silicon slurry and natural graphite is 1:3, and the particle diameter D of described natural graphite 50 25 μm;

[0099] (2) Under argon, roast the mixture described in step (1) at 800°C for 4 hours, and break it to obtain particle size D 50 15μm silicon carbon anode material;

[0100] (3) Perfluoromethyl vinyl ether, maleic anhydride and 2-vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com