Tunneling device and method suitable for soft rock stratum

A technology of tunneling and formation, which is applied in the direction of tunneling, earthwork drilling, cutting machinery, etc. It can solve the problems of poor health of construction workers, slow excavation speed and consumption, and dust pollution of the environment, so as to save manpower and material resources and speed up excavation progress , the effect of reducing the amount of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 of the present invention provides a tunnel excavation device suitable for soft rock formations, including: a transmission mechanism, a blade type excavation mechanism and a hydraulic propulsion mechanism;

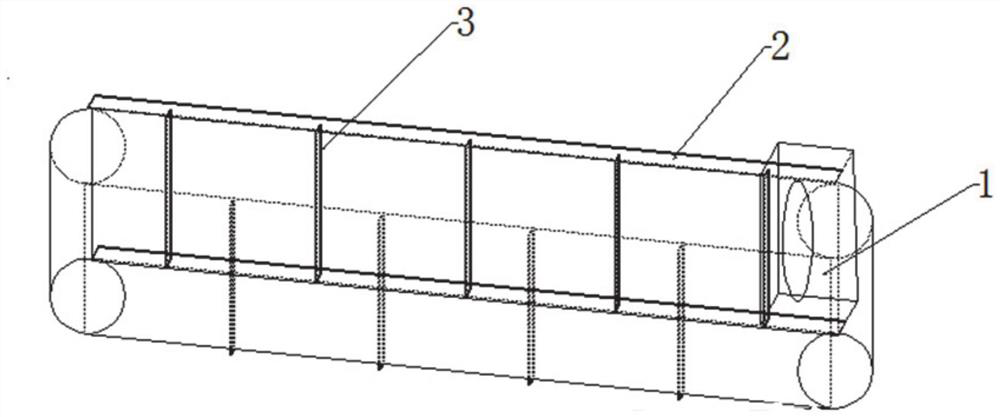

[0039] Such as figure 1 As shown, there are protrusions 3 on the conveyor belt of the transmission mechanism, and there are baffles 2 on the left and right, and there is a soil collecting device 1 at the end. The way of splicing and connecting is that the previous conveyor belt slag transporting device transports the slag to the top of the next conveyor belt slag transporting device and pours the slag into the soil collecting device 1 of the next conveyor belt slag transporting device.

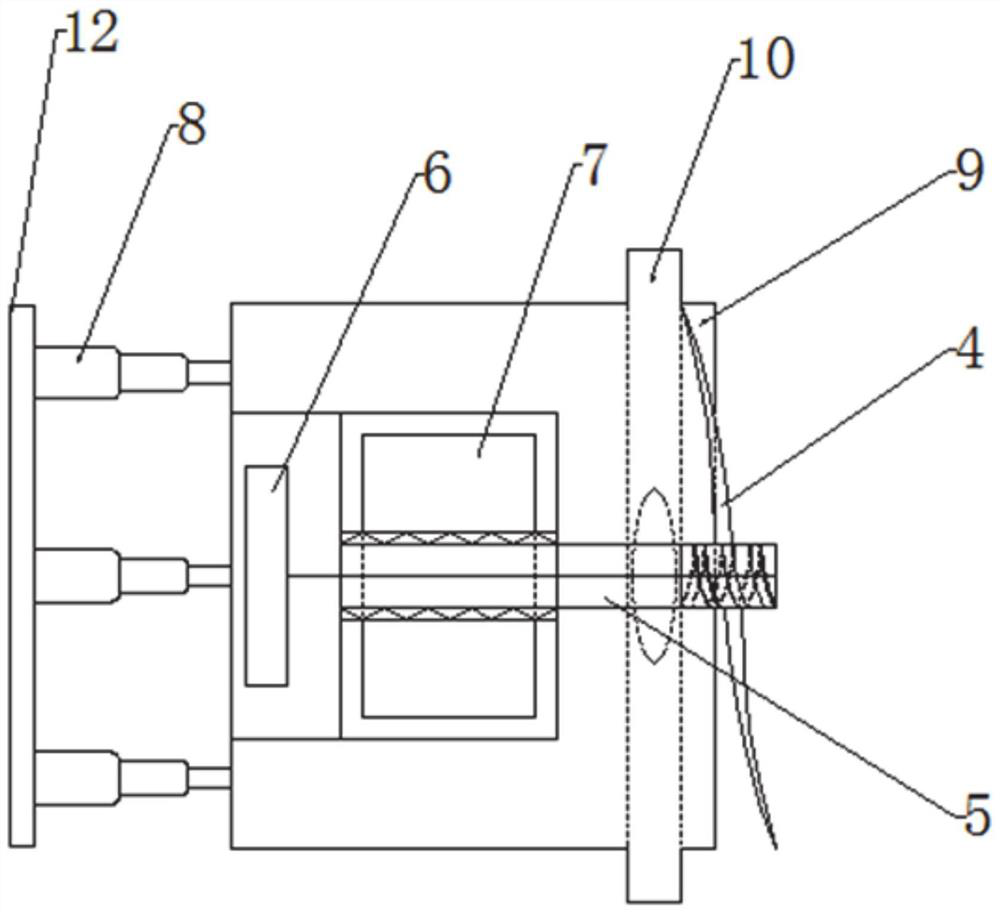

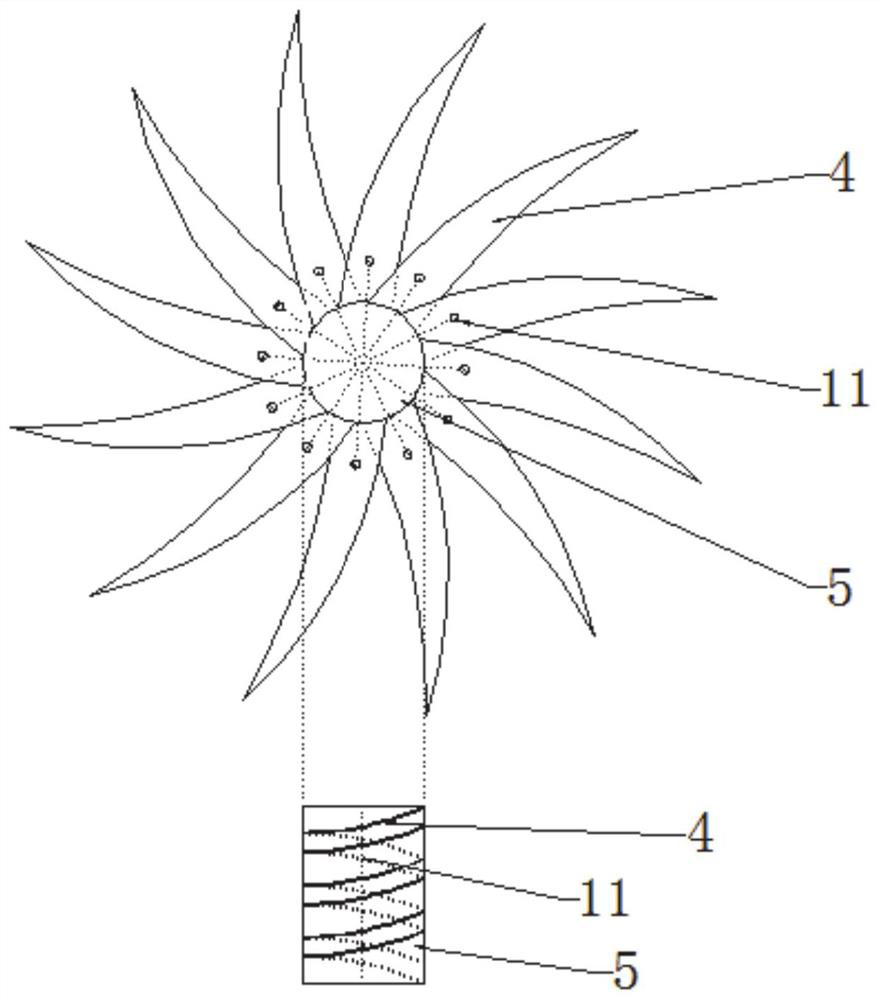

[0040] Such as figure 2 As shown, the blade type excavating device includes a screw blade mechanism 4, a transmission shaft 5, a high-pressure water pump 6, a water collecting device 9 and an excavation port 10, and the hydraulic propulsion mechanism includes a reactio...

Embodiment 2

[0049] Embodiment 2 of the present invention provides a method suitable for tunneling in soft rock formations, comprising the following steps:

[0050] Step 1: Determine the location of the excavation, and place the blade type excavation device and the reaction support at the designated location;

[0051] Step 2: According to the footage length of the tunnel, estimate the number of conveyor belt slag transport devices and place the conveyor belt slag transport devices at designated locations;

[0052] Step 3: Start the motor to drive the blades to cut the soil, and at the same time, the water outlet hole is sprayed to the excavated soil to realize automatic mechanized excavation, and the soil falls into the spliced conveyor belt through the excavation port to realize automatic slag discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com