Anti-allergy toothpaste and preparation method thereof

An anti-sensitivity and toothpaste technology, applied in the field of oral care, can solve the problems of single ingredient and insignificant effect, and achieve the effect of high affinity and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

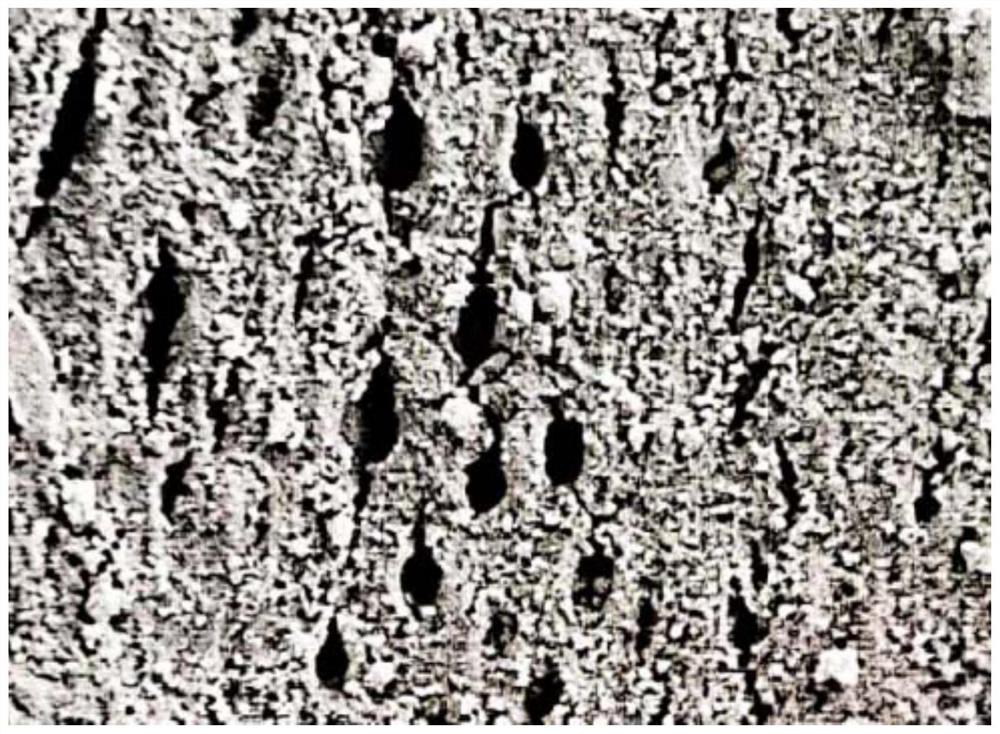

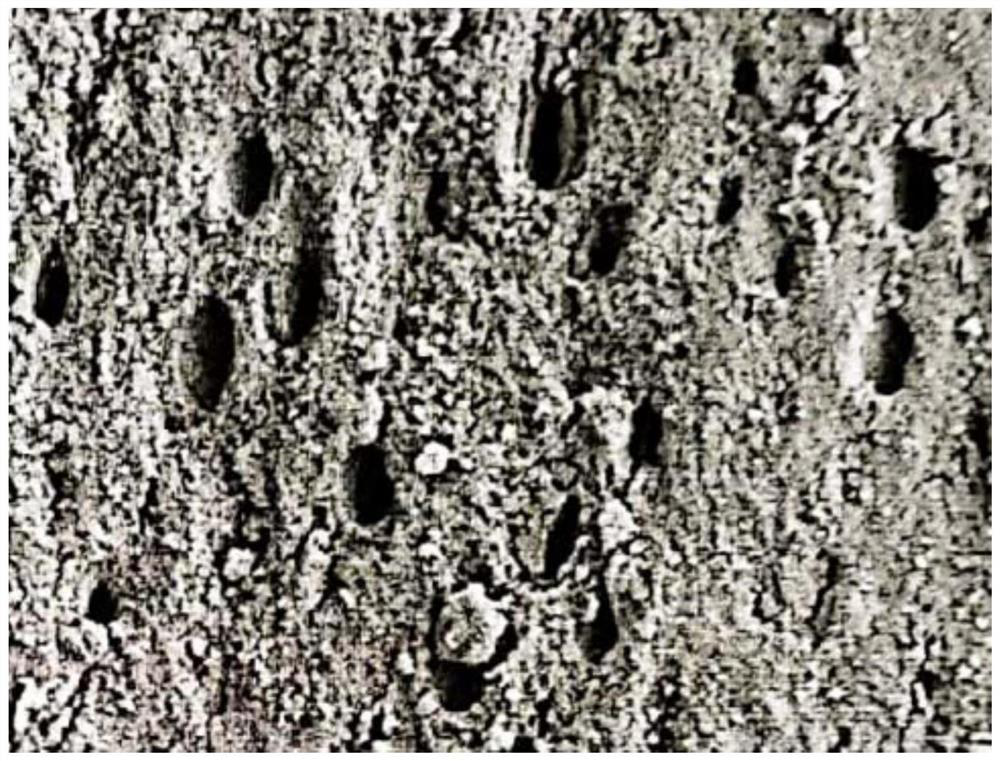

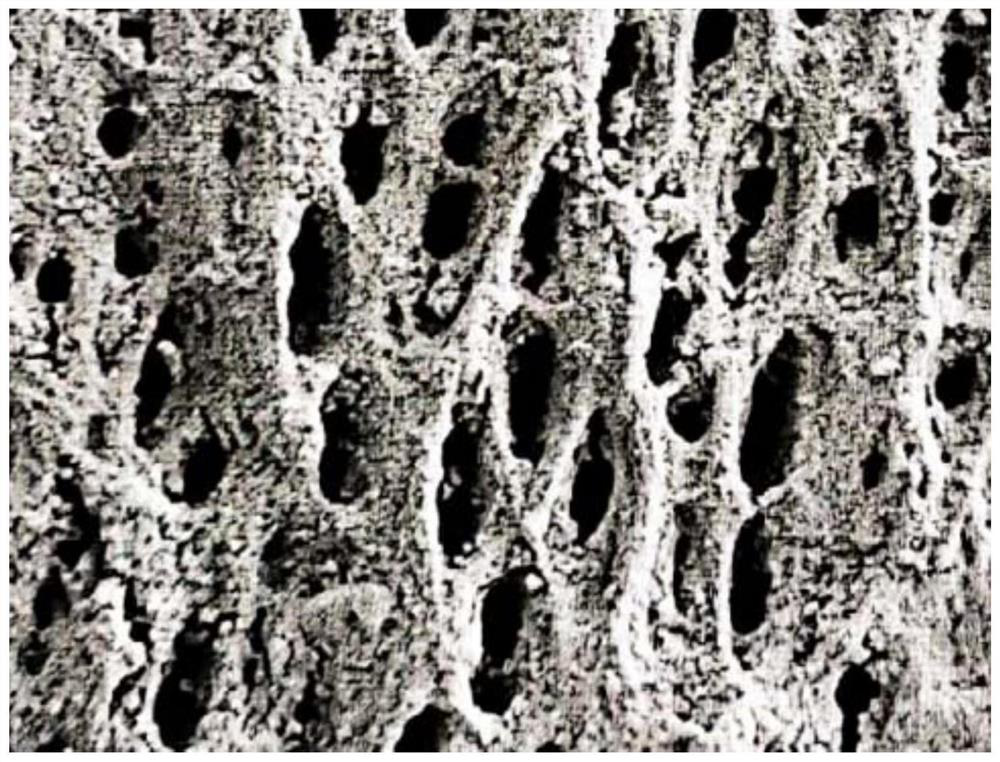

Image

Examples

Embodiment 1

[0025] The preparation of the anti-sensitive toothpaste in this example is carried out in a paste making machine specially used for preparing toothpaste, and the model of the paste making machine is ZG1300.

[0026] The specific preparation steps of anti-sensitive toothpaste are as follows:

[0027] S1. Weigh 200kg of sorbitol, 80kg of glycerin, 5kg of polyethylene glycol-8, 1kg of cellulose gum, 1kg of guar gum, 20kg of hydroxyapatite, 10kg of potassium nitrate, 0.1kg of tranexamic acid, 2kg of tetrasodium pyrophosphate, Sodium monofluorophosphate 2.4kg, clean hydrated silica 20kg, thickening hydrated silica 20kg, sodium saccharin 1kg, sodium benzoate 1.5kg, silicon dioxide 2kg, sodium lauryl sulfate 12kg, sodium lauroyl sarcosinate 2kg, essence 4kg and 290kg of water;

[0028] S2. Add water to the pre-dispersion pot, add liquid phase raw materials, and obtain liquid phase mixed liquid;

[0029] S3. Turn on the vacuum to -0.04MPa, inhale the liquid phase mixture, turn on th...

Embodiment 2

[0038] The preparation of the anti-sensitive toothpaste in this example is carried out in a paste making machine specially used for preparing toothpaste, and the model of the paste making machine is ZG1300.

[0039] The specific preparation steps of anti-sensitive toothpaste are as follows:

[0040] S1. Weigh 250kg of sorbitol, 100kg of glycerin, 20kg of polyethylene glycol-8, 3kg of cellulose gum, 5kg of guar gum, 50kg of hydroxyapatite, 25kg of potassium nitrate, 0.3kg of tranexamic acid, 6kg of tetrasodium pyrophosphate, Sodium monofluorophosphate 8.3kg, clean hydrated silica 55kg, thickening hydrated silica 61kg, sodium saccharin 2.5kg, sodium benzoate 2.3kg, silicon dioxide 2kg, sodium lauryl sulfate 21kg, sodium lauroyl sarcosinate 5kg, Flavor 6kg and water 340kg;

[0041] S2. Add water to the pre-dispersion pot, add liquid phase raw materials, and obtain liquid phase mixed liquid;

[0042] S3. Turn on the vacuum to -0.05MPa, inhale the liquid phase mixture, turn on th...

Embodiment 3

[0051] The preparation of the anti-sensitive toothpaste in this example is carried out in a paste making machine specially used for preparing toothpaste, and the model of the paste making machine is ZG1300.

[0052] The specific preparation steps of anti-sensitive toothpaste are as follows:

[0053]S1. Weigh 300kg of sorbitol, 120kg of glycerin, 25kg of polyethylene glycol-8, 7kg of cellulose gum, 7kg of guar gum, 120kg of hydroxyapatite, 50kg of potassium nitrate, 1.5kg of tranexamic acid, 8kg of tetrasodium pyrophosphate, Sodium monofluorophosphate 12.1kg, clean hydrated silica 100kg, thickening hydrated silica 80kg, sodium saccharin 3.5kg, sodium benzoate 3kg, silicon dioxide 3kg, sodium lauryl sulfate 32kg, sodium lauroyl sarcosinate 7kg, essence 15kg and 400kg of water;

[0054] S2. Add water to the pre-dispersion pot, add liquid phase raw materials, and obtain liquid phase mixed liquid;

[0055] S3. Turn on the vacuum to -0.05MPa, inhale the liquid phase mixture, turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com