Small villiaumite reactor passive residual discharge system based on integrated heat exchanger

A heat exchanger and integrated technology, applied in the field of passive exhaust system of small-scale fluoride salt reactor, can solve problems such as difficult to work normally, high temperature, unsuitable to install residual exhaust heat exchanger, etc., to achieve miniaturization, ratio Large heat, good for heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention provides a small fluoride-salt reactor passive exhaust system based on an integrated heat exchanger. The present invention will be further described in detail with reference to the accompanying drawings.

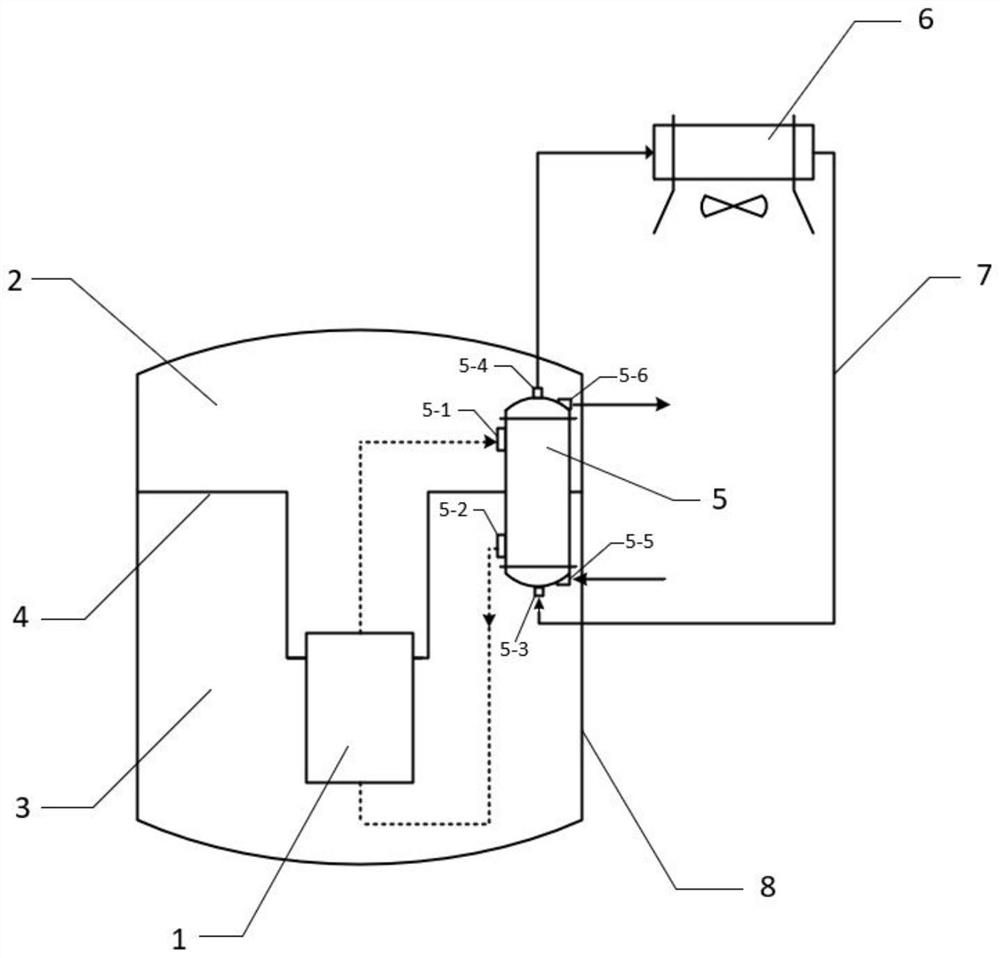

[0027] Such as figure 1 As shown, it is an embodiment of the passive exhaust system of a small-scale fluoride-salt reactor based on an integrated heat exchanger of the present invention.

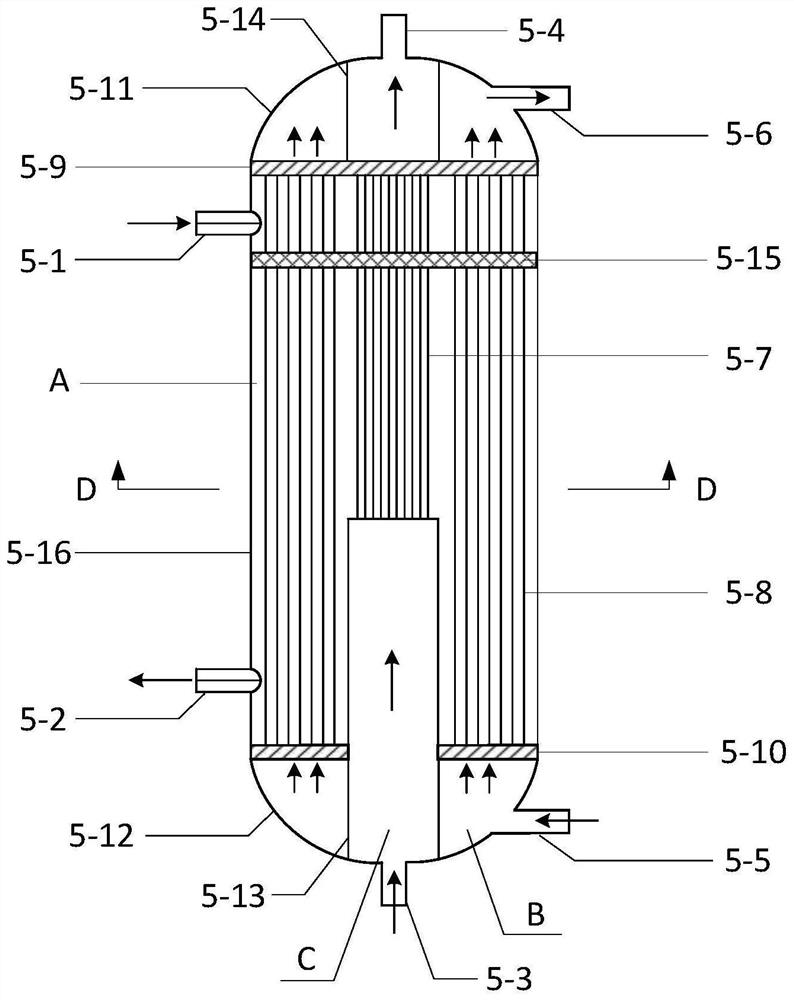

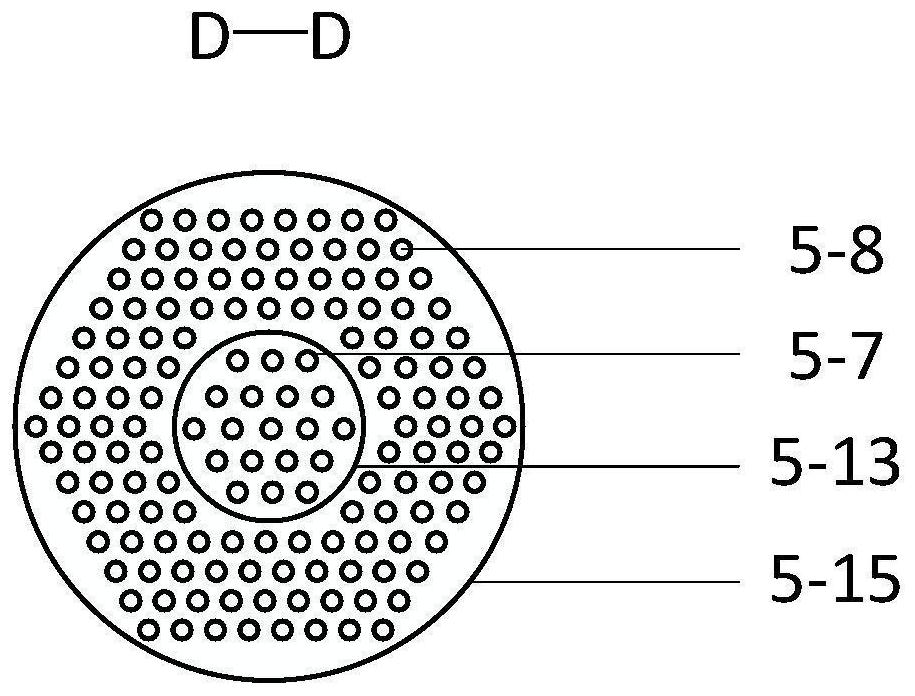

[0028] Including the core 1 located in the reactor vessel 8, the hot pool 2, the cold pool 3 below the hot pool 2, the cold and hot pool separator 4 between the hot pool 2 and the cold pool 3, and the The main heat-waste heat integrated heat exchanger 5, the air cooler 6 located outside the reactor vessel 8, and the residual discharge circuit pipe 7 connecting the main heat-waste heat integrated heat exchanger 5 and the air cooler 6; the core 1 runs through the cold and hot pool The partition 4, the lower inlet of the core 1 is located in the cold pool 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com