Air layer anti-icing and de-icing system based on air heat de-icing technology and design method of air layer anti-icing and de-icing system

A technology of air layer and technology, which is applied in the field of air layer anti-icing system, can solve the problems that long fan blades cannot achieve uniform deicing, cannot achieve deicing effect, and cannot be effectively heated, so as to ensure heating, facilitate maintenance, and heat The effect of a thin layer of air uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

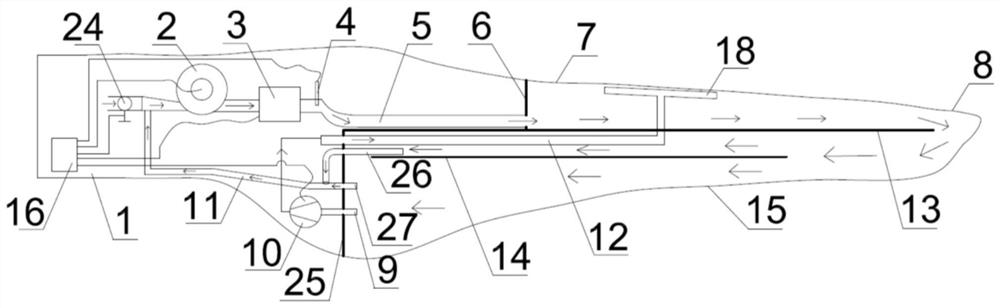

[0045] Such as figure 1 , is the air layer anti-icing system based on the air-thermal deicing technology of the present invention. A hot air generation and circulation system is built inside the blade. The airflow output by the blower 2 enters the heater 3. An electric heating wire is arranged inside the heater 3, and the air and electricity generate heat. The electric heating wire is in full contact with the hot airflow heated to a suitable temperature range (not exceeding 70°C), and a thermocouple 4 is arranged at the outlet of the heater 3 to measure the airflow temperature, and its signal is set at the controller at the blade root 1 16 to collect and feed back the operation of the control equipment.

[0046] Since the deicing demand of the blade root and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com