A kind of hea-sic high temperature wave-absorbing material and preparation method thereof

A wave absorbing material, high temperature technology, applied in the fields of magnetic/electric field shielding, antennas, electrical components, etc., can solve the problem of material wave absorbing stealth degradation and other problems, achieve outstanding anti-oxidation ability, good controllability of process parameters, easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

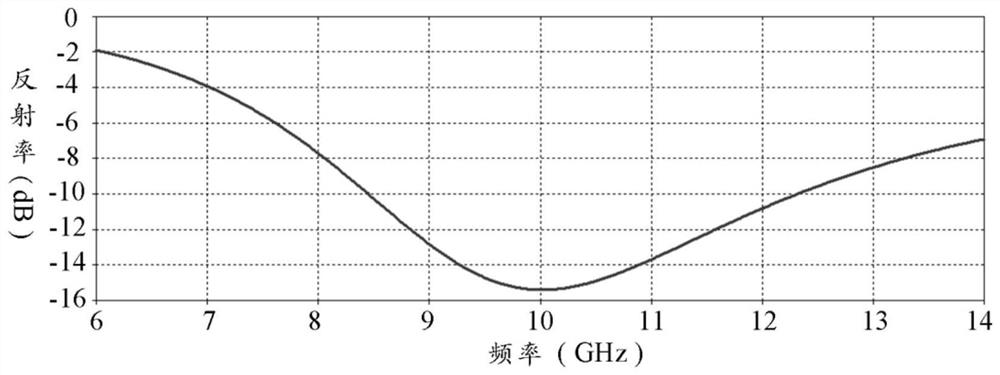

Image

Examples

Embodiment 1

[0026] A preparation method of the FeCoNiMo-SiC high temperature resistant wave-absorbing material of this embodiment, comprising the following steps:

[0027] (1) Preparation of FeCoNiMo powder: Fe, Co, Ni, and Mo powders with a commercially available purity of ≥99.5% and a particle size of 70 μm are subjected to high-energy ball milling in an equimolar ratio, the ball milling speed is 300 rpm, and the ball-to-material ratio is 7:1 , the single rotation during the ball milling process is limited to 30 minutes, and after stopping for 5 minutes, the ball milling is carried out in the form of reverse rotation. In this cycle, the total time of ball milling is 80 hours, and argon protection is implemented throughout the process.

[0028] (2) Ball milling and mixing FeCoNiMo-SiC composite powder: Weigh the FeCoNiMo powder obtained in step (1) respectively according to the mass fraction ratio of 35:55:10, commercially available SiC powder with a purity ≥ 99% and a particle size of 20...

Embodiment 2

[0032] A preparation method of the FeCoNiMoAlTiSi-SiC high temperature resistant wave-absorbing material of this embodiment, comprising the following steps:

[0033](1) Preparation of FeCoNiMoAlTiSi powder: the Fe, Co, Ni, Mo, Al, Ti, Si powders with a commercially available purity ≥ 99.5% and a particle size of 20 μm are subjected to high-energy ball milling in equimolar proportions, and the ball milling speed is 300 rpm. The material ratio is 15:1, and the single rotation during the ball milling process is limited to 30 minutes. After stopping for 10 minutes, the ball milling is carried out in the form of reverse rotation. In this cycle, the total time of ball milling is 10 hours, and the whole process is protected by argon.

[0034] (2) Ball milling and mixing FeCoNiMoAlTiSi-SiC composite powder: Weigh the FeCoNiMoAlTiSi powder obtained in step (1) according to the mass fraction ratio of 5:92:3, and commercially available SiC powder with a purity ≥ 99% and a particle size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com