Mineral composite anti-seepage material, usage method and anti-seepage fiber bag prepared from mineral composite anti-seepage material

A technology of composite anti-seepage and anti-seepage materials, which is applied in the field of mineral composite anti-seepage materials, can solve the problems of high cost, achieve the effects of convenient use, resource utilization, and huge output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

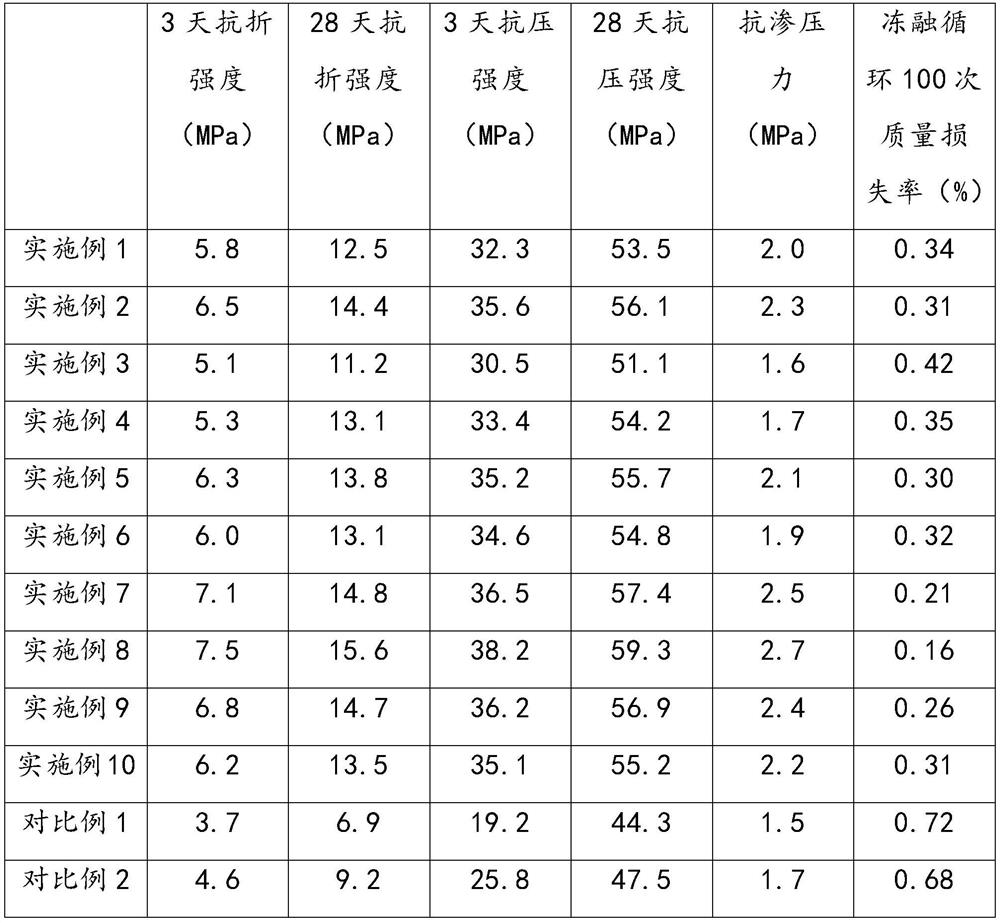

Examples

Embodiment 1

[0046] A mineral composite anti-seepage material described in this embodiment includes the following components by mass: 30 parts of granite saw mud, 30 parts of red mud, 20 parts of steel slag, 20 parts of spodumene tailings, 3 parts of alkali activator, 1.5 parts of water reducing agent. All raw materials are directly mixed, crushed and sieved, the particle size is less than 30μm.

[0047] When adding water to form, the ratio of water to filler is 1:1.

Embodiment 2

[0049] A mineral composite anti-seepage material described in this embodiment includes the following components by mass: 30 parts of granite saw mud, 30 parts of red mud, 20 parts of steel slag, 20 parts of spodumene tailings, 4 parts of alkali activator, 1.5 parts of water reducer.

[0050] Other preparation steps are the same as in Example 1.

[0051] When adding water to form, the ratio of water to filler is 1:1.

Embodiment 3

[0053] A mineral composite anti-seepage material described in this embodiment comprises the following components by mass: 30 parts of granite saw mud, 30 parts of red mud, 20 parts of steel slag, 20 parts of spodumene tailings, 5 parts of alkali activator, 1.5 parts of water reducing agent.

[0054] Other preparation steps are the same as in Example 1.

[0055] When adding water to form, the ratio of water to filler is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com