Welding method for heterogeneous titanium alloy T-shaped joint

A welding method and titanium alloy technology, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve problems such as increasing the difficulty of welding beta titanium alloys, reduce root cleaning and grinding and other processes, reduce Temperature gradient, effect of promoting metallurgical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

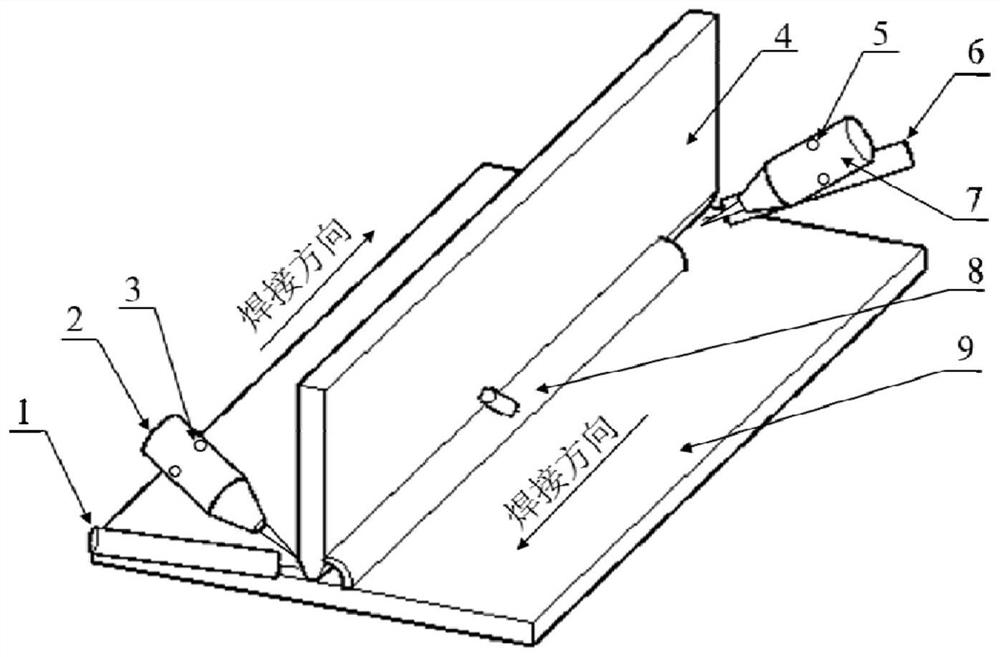

[0029] A method for welding a heterogeneous titanium alloy T-joint with a plate thickness of 5mm, comprising the following steps:

[0030] (1) Before welding, process the part to be welded of the titanium alloy rib plate 4 into a K-shaped groove as required, with a blunt edge of 2mm and a groove angle of 30°, and grind or clean the surfaces on both sides of the processed workpiece, Fixed on the welding fixture;

[0031](2) Coaxial powder-feeding laser cladding is adopted, and the laser is applied to the area to be welded on both sides of the T-shaped joint. The periodically swinging MIG welding torch is placed behind the laser beam in a side-axis connection. Adjust the MIG welding torch, The angle between the laser beam and the rib plate 4 is guaranteed to be in the same plane, the angle between the MIG welding torch and the laser beam is 25°, the angle between the laser beam and the rib plate 4 is 40°, and the distance between the powder feeding nozzle and the laser beam The...

Embodiment 2

[0036] A method for welding a heterogeneous titanium alloy T-joint with a plate thickness of 7 mm, comprising the following steps:

[0037] (1) Before welding, process the part to be welded of the titanium alloy rib plate 4 into a K-shaped groove as required, with a blunt edge of 2mm and a groove angle of 30°, and grind or clean the surfaces on both sides of the processed workpiece, Fixed on the welding fixture;

[0038] (2) Coaxial powder-feeding laser cladding is adopted, and the laser is applied to the area to be welded on both sides of the T-shaped joint. The periodically swinging MIG welding torch is placed behind the laser beam in a side-axis connection. Adjust the MIG welding torch, The angle between the laser beam and the rib plate 4 is guaranteed to be in the same plane, the angle between the MIG welding torch and the laser beam is 25°, the angle between the laser beam and the rib plate 4 is 40°, and the distance between the powder feeding nozzle and the laser beam T...

Embodiment 3

[0043] A method for welding a heterogeneous titanium alloy T-joint with a plate thickness of 12mm, comprising the following steps:

[0044] (1) Before welding, process the part to be welded of the titanium alloy rib plate 4 into a K-shaped bevel as required, with a blunt edge of 4mm and a bevel angle of 40°, and grind or clean the surfaces on both sides of the processed workpiece, Fixed on the welding fixture;

[0045] (2) Coaxial powder-feeding laser cladding is adopted, and the laser is applied to the area to be welded on both sides of the T-shaped joint. The periodically swinging MIG welding torch is placed behind the laser beam in a side-axis connection. Adjust the MIG welding torch, The angle between the laser beam and the rib plate 4 is guaranteed to be in the same plane, the angle between the MIG welding torch and the laser beam is 45°, the angle between the laser beam and the rib plate 4 is 75°, and the distance between the powder feeding nozzle and the laser beam The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com