Method for preparing high-coercive force neodymium-iron-boron magnet through macroscopic non-uniform diffusion

A uniform diffusion and high coercive force technology, applied in the direction of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of excessive magnet strengthening, waste, and heavy rare earth elements cannot be fully utilized, and achieve magnet performance improvement , save usage, and improve overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

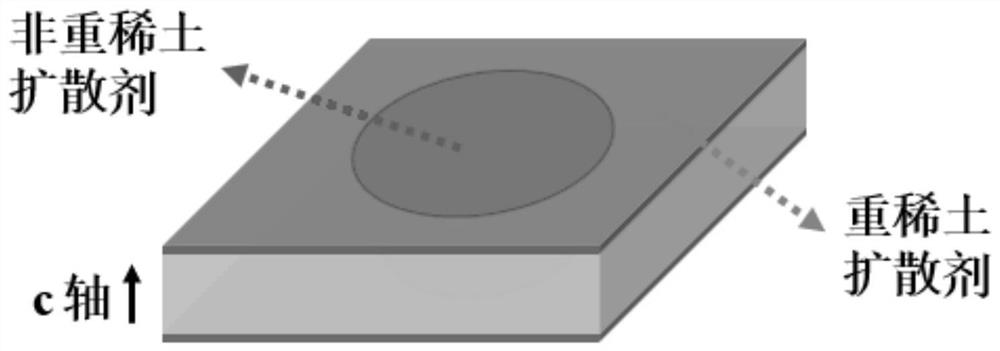

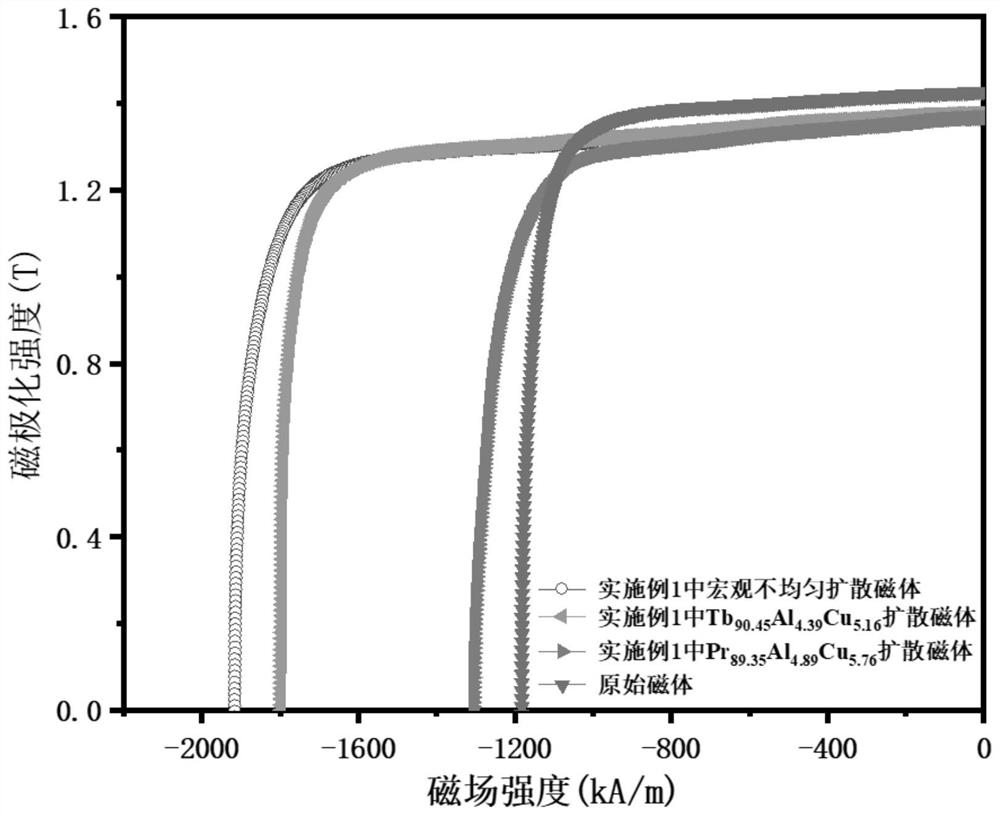

[0040] In this example, high coercive force NdFeB magnets are prepared by macroscopic inhomogeneous diffusion of Tb-Al-Cu and Pr-Al-Cu:

[0041] (1) Preparation of heavy rare earth-containing Tb by arc melting 90.45 al 4.39 Cu 5.16 Alloy ingot and Pr without heavy rare earth 89.35 al 4.89 Cu 5.76 (wt%) alloy ingot with low melting point.

[0042] (2) Remelting and spray-casting the two alloy ingots obtained in step (1) respectively to obtain strips corresponding to the two alloys.

[0043] (3) Coarsely crushing the two alloy strips obtained in step (2) respectively to obtain two alloy powders passing through a 60-mesh sieve.

[0044](4) Mix the two alloy powders obtained in step (3) with an organic binder (PVA glue) respectively to obtain a heavy rare earth diffusing agent and a non-heavy rare earth diffusing agent.

[0045] (5) Use 52M sintered NdFeB magnets as the diffusion substrate, cut into cuboid samples by wire cutting, the size is 7×7×4mm, and the 4mm thickness ...

Embodiment 2

[0050] In this example, high coercive force NdFeB magnets are prepared by macro-inhomogeneous diffusion of Tb-Al-Cu and Al-Cu:

[0051] (1) Preparation of heavy rare earth-containing Tb by arc melting 90.45 al 4.39 Cu 5.16 Alloy ingot and Al without heavy rare earth 70.63 Cu 29.37 (wt%) alloy ingot with low melting point.

[0052] (2) Remelting and spray-casting the two alloy ingots obtained in step (1) respectively to obtain strips corresponding to the two alloys.

[0053] (3) Coarsely crushing the two alloy strips obtained in step (2) respectively to obtain two alloy powders passing through a 60-mesh sieve.

[0054] (4) Mix the two alloy powders obtained in step (3) with an organic binder (PVA glue) respectively to obtain a heavy rare earth diffusing agent and a non-heavy rare earth diffusing agent.

[0055] (5) Use N50 sintered NdFeB magnets as the diffusion substrate, cut into cuboid samples by wire cutting, the size is 7×7×3mm, and the direction of 3mm thickness is ...

Embodiment 3

[0060] In this example, high coercive force NdFeB magnets are prepared by macroscopic inhomogeneous diffusion of Tb-Al-Cu and Pr-Al-Cu:

[0061] (1) Preparation of heavy rare earth-containing Tb by arc melting 90.45 al 4.39 Cu 5.16 Alloy ingot and Pr without heavy rare earth 89.35 al 4.89 Cu 5.76 (wt%) alloy ingot with low melting point.

[0062] (2) Remelting and spray-casting the two alloy ingots obtained in step (1) respectively to obtain strips corresponding to the two alloys.

[0063] (3) Coarsely crushing the two kinds of alloy strips obtained in step (2) respectively to obtain two kinds of powders passing through a 60-mesh sieve.

[0064] (4) Mix the two alloy powders obtained in step (3) with an organic binder (PVA glue) respectively to obtain a heavy rare earth diffusing agent and a non-heavy rare earth diffusing agent.

[0065] (5) Use N50 sintered NdFeB magnets as the diffusion substrate, cut into cylindrical samples by wire cutting, the size is φ10×3mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coercivity | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com