Electrochemical remediation method for lead-zinc combined polluted soil based on deep-eutectic solvent

A technology of deep eutectic solvent and complex pollution, applied in the restoration of contaminated soil, etc., can solve the problems of long cycle and inapplicability of bioremediation technology, and achieve the effects of low vapor pressure, strong conductivity and good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

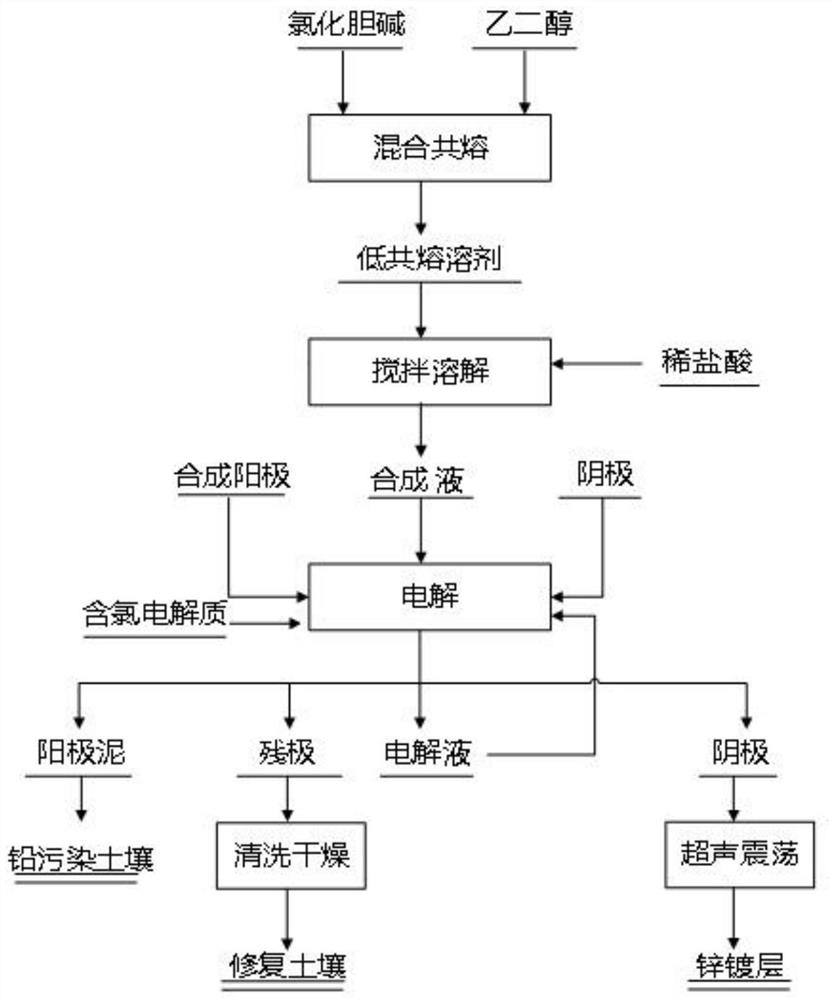

[0027] Electrochemical repair method of lead zinc composite contaminated soil based on low-molten solvent, the specific steps are as follows:

[0028] (1) mixing the choline and ethylene glycol in accordance with the molar ratio of 1: 2, then heating the mixture at 70 ° C to clear the clear transparent liquid, synthesize cholinergic-ethylene glycol low melting solvent (1CHCl : 2EG DES);

[0029] (2) Dilute hydrochloric acid is added to the 1chCl: 2EG DES synthesized to step (1), and the mixture is uniform, and the synthetic solution is formulated, injecting the electrolytic cell;

[0030] (3) The electrolyte prepared by step (2) is heated to 60 ° C, and the contaminated soil is an anode (soil volume and the pouring agent ratio of 10: 1), the copper sheet is a cathode, and the area ratio of the anode and the cathode is 2: 1, the yin anodic pitch is 9cm, and the cation exchange film is provided at 3 cm between the cathode between the cathode, and the chlorine-containing electrolyte ...

Embodiment 2

[0034] Electrochemical repair method of lead zinc composite contaminated soil based on low-molten solvent, the specific steps are as follows:

[0035] (1) mixing the choline and ethylene glycol in accordance with the molar ratio of 1: 2, then heating the mixture at 70 ° C to clear the clear transparent liquid, synthesize cholinergic-ethylene glycol low melting solvent (1CHCl : 2EG DES);

[0036] (2) Dilute hydrochloric acid is added to the 1chCl: 2EG DES synthesized to step (1), and the mixture is uniform, and the synthetic solution is formulated, injecting the electrolytic cell;

[0037] (3) The electrolyte prepared by step (2) is heated to 60 ° C to contaminate the soil as an anode (the soil volume and the pouring agent ratio of 10: 2), the copper sheet is the cathode, and the area ratio of the anode and the cathode is 2: 1, the yin anodic polar spacing is 6 cm, and the cation exchange film is provided at 2cm from the cathode between the cathode, the chlorine-containing electrol...

Embodiment 3

[0041] Electrochemical repair method of lead zinc composite contaminated soil based on low-molten solvent, the specific steps are as follows:

[0042] (1) mixing the choline and ethylene glycol in accordance with the molar ratio of 1: 2, then heating the mixture at 70 ° C to clear the clear transparent liquid, synthesize cholinergic-ethylene glycol low melting solvent (1CHCl : 2EG DES);

[0043] (2) Dilute hydrochloric acid is added to the 1chCl: 2EG DES synthesized to step (1), and the mixture is uniform, and the synthetic solution is formulated, injecting the electrolytic cell;

[0044](3) Step (2) Preparation of electrolytic solution was heated to 60 ℃, as an anode in contaminated soil (soil volume to volume ratio of pore forming agent was 10: 3), copper cathode, anode and the cathode to control the area ratio of 2: 1, anode and cathode spacing is 6cm, the cation exchange membrane disposed between the electrodes from the cathode at 2cm yin and yang, the chlorine-containing elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com