Mechanical equipment abnormal sound detection method based on self-supervised feature extraction

A technology for mechanical equipment and feature extraction, which is applied in the testing of mechanical components, neural learning methods, testing of machine/structural components, etc., can solve the problems of low accuracy and poor correlation of abnormal sound detection of mechanical equipment, and achieve high accuracy , the effect of improving the accuracy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

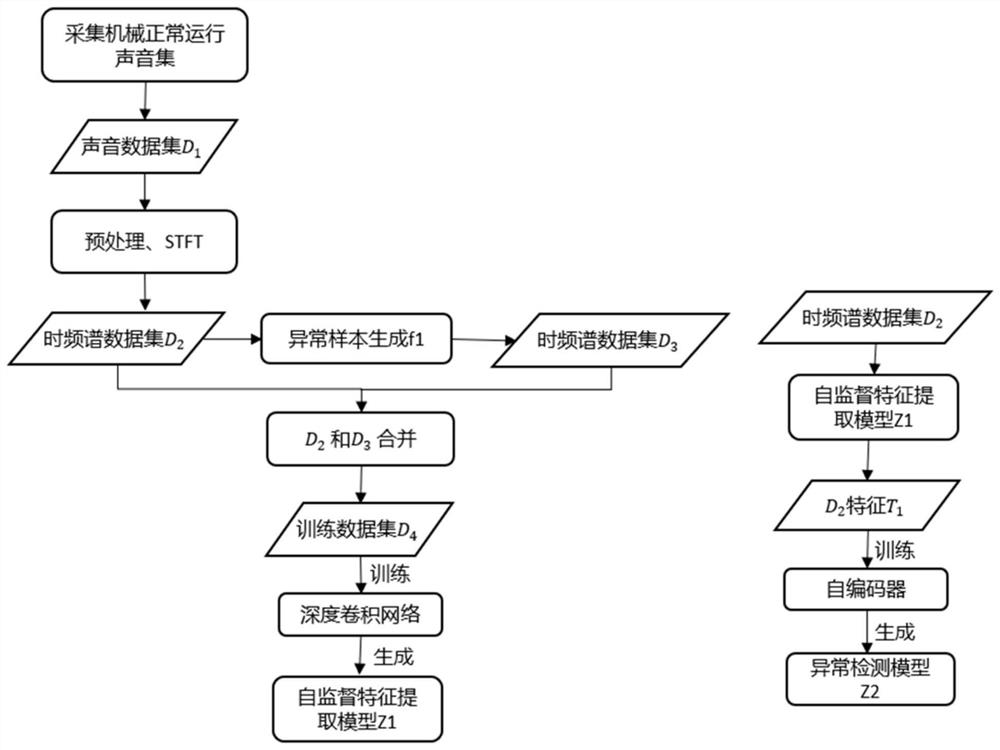

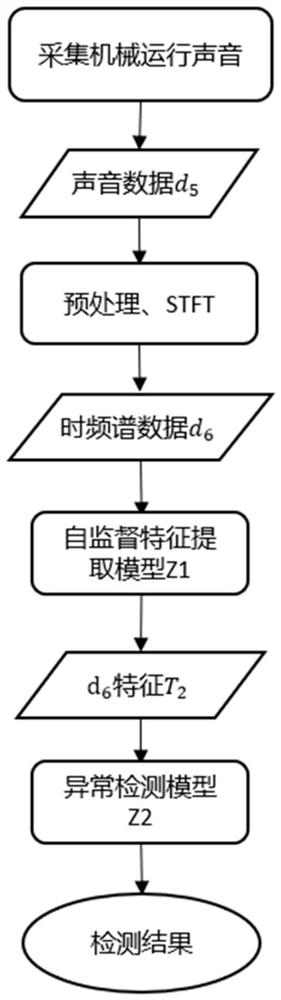

[0048] Such as figure 1 with figure 2 As shown, the present invention proposes a method for detecting abnormal sound of mechanical equipment based on self-supervised feature extraction, including the following steps:

[0049] S1. Acquisition of normal operation sound data set D of mechanical equipment 1 ;

[0050] S2. Perform preprocessing and short-time Fourier transform (STFT) on all data samples to obtain normal sample time spectrum data set D 3 ;

[0051] S3. Spectrum data set D when using normal samples 2 Spectrum dataset D when abnormal samples are generated 3 ;

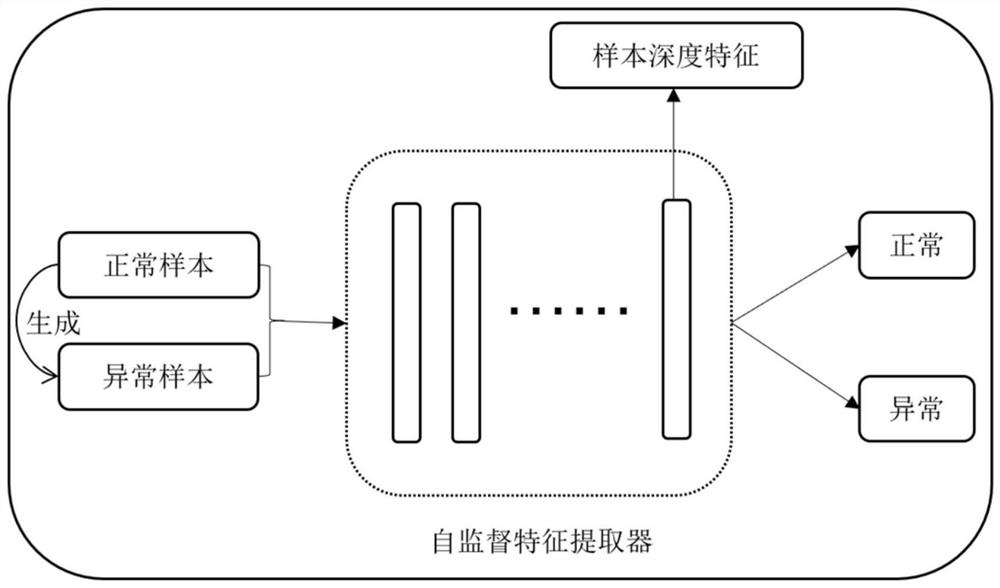

[0052] S4. The normal sample time spectrum data set D 2 and the generated abnormal sample time spectrum data set D 3 Combined into training data set D 4 , using D 4 Train a deep convolutional network to generate a self-supervised feature extraction model Z1;

[0053] S5. Use the self-supervised feature extraction model Z1 to extract D 2 feature T 1 , then use T 1 Train the autoencoder network to ...

Embodiment 2

[0081] Such as Figure 5 As shown, the present invention provides a mechanical equipment abnormal sound detection system based on self-supervised feature extraction, including a normal operation sound data set acquisition module, a normal sample time spectrum data set acquisition module, an abnormal sample time frequency spectrum data set acquisition module, and a self-supervised Feature extraction model generation module, abnormal detection model generation module and abnormal sound detection module;

[0082] The normal operation sound data set acquisition module is used to collect the normal operation sound data set D of mechanical equipment 1 ;

[0083] The normal sample time spectrum data set acquisition module is used to preprocess and short-time Fourier transform all data samples to obtain the normal sample time spectrum data set D 2 ;

[0084] The frequency spectrum data set acquisition module for the abnormal samples is used to use the normal sample time spectrum da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com