Ternary composite gas sensing chip, preparation method, application method, and gas sensing material

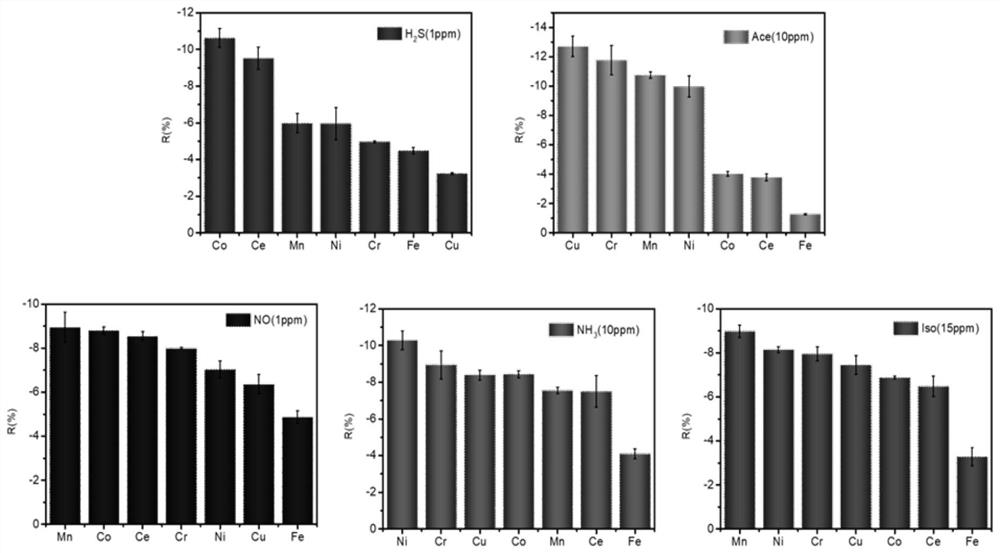

A gas sensing and ternary composite technology, applied in the field of gas sensing, can solve the problems of large error, cumbersome operation process, and difficulty in industrialization, and achieve the effects of improving response sensitivity, realizing recognition ability, and improving gas selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

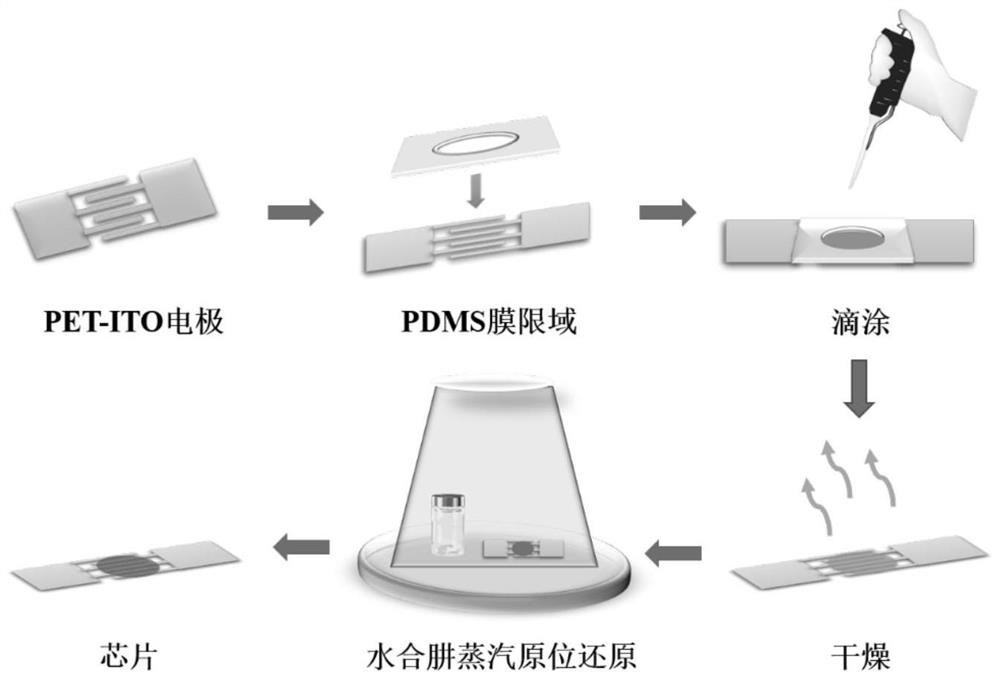

[0043] Such as figure 1 As shown, the present invention discloses a method for preparing a ternary composite gas sensor chip, comprising the following steps:

[0044] Step 1: Mix an equal volume of graphene oxide solution and metal ion solution, shake evenly, add a small amount of PDDA (Poly dimethyl dially ammonium chloride, polydiallyl dimethyl ammonium chloride), shake on the shaker Overnight, then centrifuged and washed several times with deionized water, and redispersed in an equal amount of deionized water to obtain a self-assembled suspension material;

[0045] Step 2: Use PDMS film to confine the ITO-PET interdigitated electrodes, and perform oxygen plasma treatment on the electrodes. Drop-coat the self-assembled suspension material prepared in Step 1 on the electrodes, dry them on the heating plate, and use Nitrogen purging, followed by reducing in reducing steam for 10-20min at 60-100°C to obtain a ternary composite gas sensor chip unit, and single or multiple terna...

Embodiment 1

[0058] This embodiment provides a method for preparing a ternary composite gas sensor chip using a molybdenum disulfide solution, and the specific steps are as follows:

[0059] Step 1: Add 0.5ml of 10mM molybdenum disulfide solution to an equal volume of 0.5mg / mL graphene oxide solution, shake evenly, then add 15μL of 1% Wt. PDDA with a molecular weight less than 100kDa, shake overnight in a shaker , then centrifuged and washed 3 times with deionized water, and redispersed in an equal amount of deionized water to obtain a self-assembled suspension material;

[0060] Step 2: Use PDMS membrane to confine the ITO-PET interdigitated electrode, and treat the electrode with oxygen plasma. Take 10 μL of the self-assembled suspension material prepared in step 1 and drop-coat it on the electrode, and dry it on the heating plate. , purged with nitrogen, and then reduced in hydrazine hydrate vapor at 80°C for 15 minutes to obtain a ternary composite gas sensor chip unit, and a single or...

Embodiment 2

[0062] This embodiment provides a method for preparing a ternary composite gas sensor chip using a cobalt chloride solution, and the specific steps are as follows:

[0063] Step 1, add 0.5ml of 10mM cobalt chloride solution to an equal volume of 0.5mg / mL graphene oxide solution, shake evenly, and then add 15μL of 1% Wt. PDDA with a molecular weight between 100-200kDa. The shaker was shaken overnight, then centrifuged and washed with deionized water for 3 times, and redispersed in the same amount of deionized water to obtain the self-assembled suspension material;

[0064]Step 2: Use PDMS membrane to confine the ITO-PET interdigitated electrode, and treat the electrode with oxygen plasma. Take 10 μL of the self-assembled suspension material prepared in step 1 and drop-coat it on the electrode, and dry it on the heating plate. , purged with nitrogen, and then reduced in hydrazine hydrate vapor at 70°C for 15 minutes to obtain a ternary composite gas sensor chip unit, and single ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com