Ceramic phase reinforced refractory high-entropy alloy composite materials and preparation method thereof

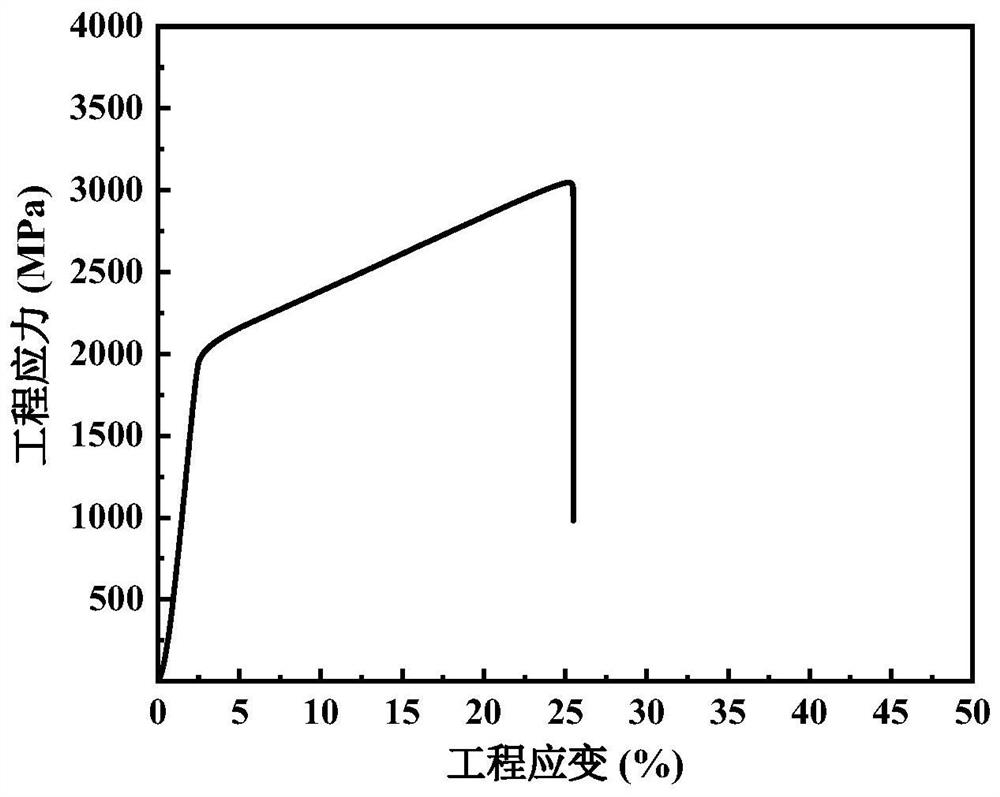

A high-entropy alloy and composite material technology is applied in the field of ceramic phase reinforced refractory high-entropy alloy composite materials and their preparation, which can solve the problems of increased preparation cost, complex alloy composition and difficulty, and achieve excellent mechanical properties at room temperature and high temperature. , the process is simple, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a ceramic phase reinforced refractory high-entropy alloy composite material, comprising the following steps:

[0031] Step 1: Take the corresponding elemental pure metal raw material according to the type of alloy component, remove the scale, ultrasonically clean and dry it, and make precise ingredients according to the alloy composition;

[0032] Step 2: Place the weighed raw materials of each element in the water-cooled copper mold crucible of the non-consumable vacuum arc melting furnace in order of the melting point of the elements from low to high, and place the ceramic phase at the bottom, and put the vacuum arc melting furnace The air pressure of the vacuum chamber is pumped to 5×10 -3 Below Pa;

[0033] Step 3: Arc smelting. In order to ensure the uniformity of the alloy, the smelting time is 160-200s each time after the alloy is melted, and each alloy ingot is smelted 6-8 times to ensure the composition is uniform;

[0034] Step 4: Take i...

Embodiment 1

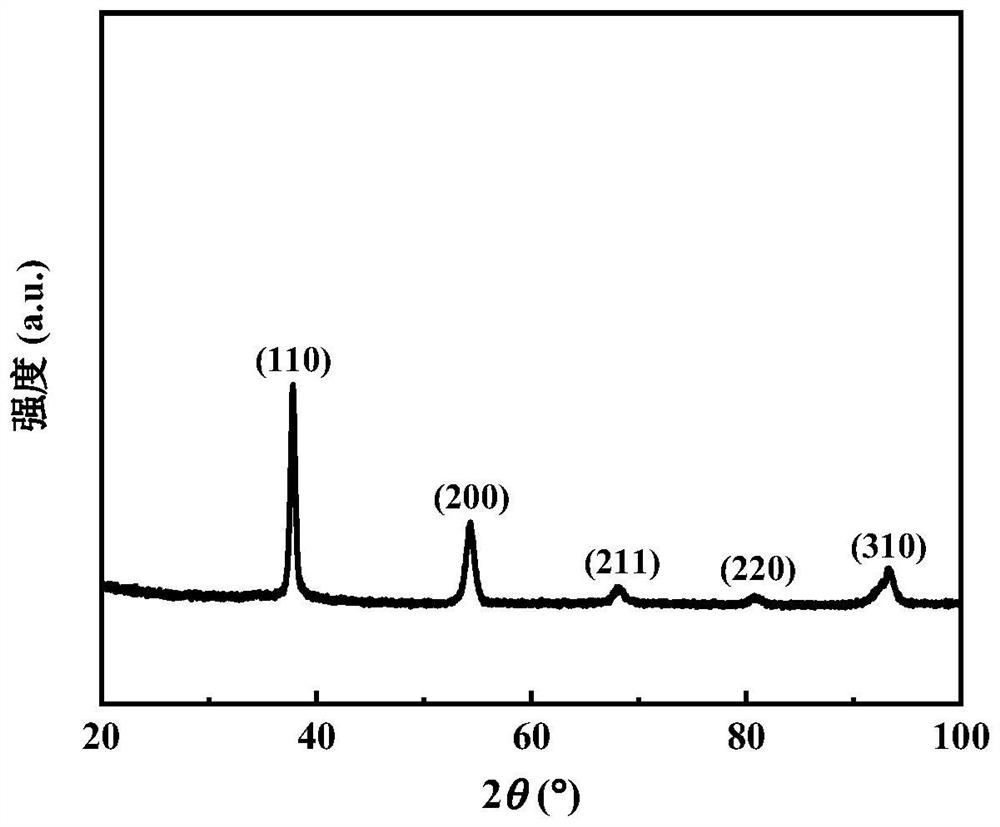

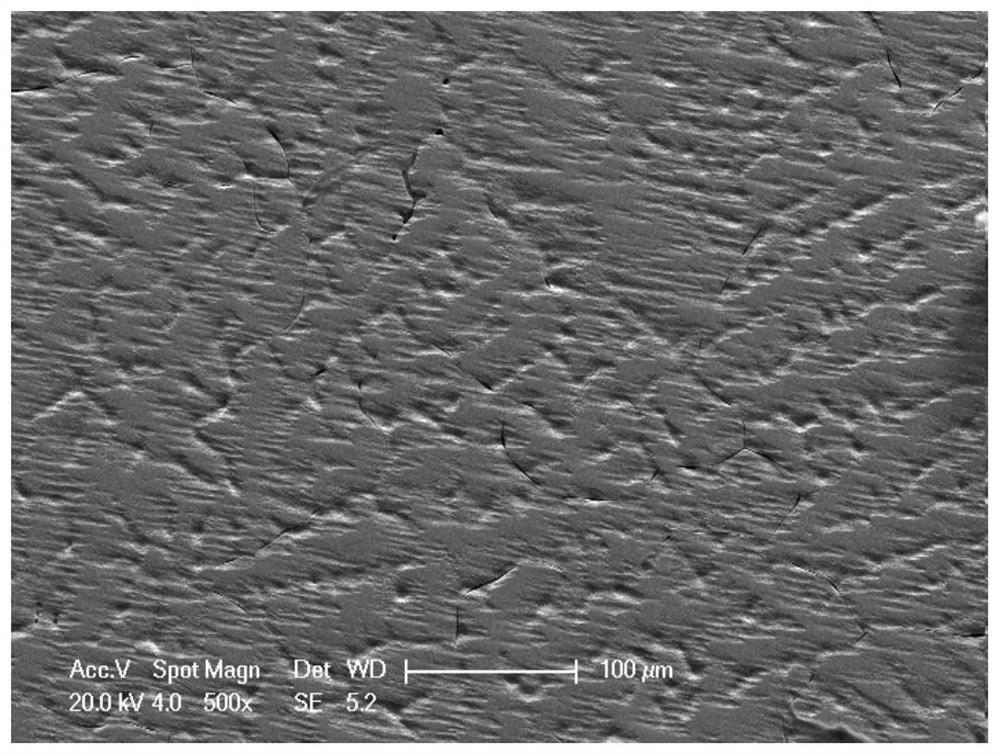

[0039] Take Al with a purity of 99.9wt.% 2 o 3 Particles and Hf, Nb, Ta, Ti, V elemental pure metal particles with a purity of not less than 99.95wt.%. After the metal particles are mechanically polished to remove scale and ultrasonically cleaned and dried, the 2 o 3 Precise batching, the ratio is 19.56at.%Hf, 19.56at.%Nb, 19.56at.%Ta, 19.56at.%Ti, 19.56at.%V, 2.2at.%Al 2 o 3 . The weighed raw materials are placed in the water-cooled copper mold crucible of the vacuum arc melting furnace in the order of the melting point of the elements from low to high, and the ceramic phase is placed at the bottom. Vacuum the chamber to 5×10 before melting - 3 Pa, filled with argon to 0.7 atmospheres. When smelting, first smelt the titanium ingot in the furnace for 180s to remove the residual oxygen in the furnace cavity; when smelting the target alloy, keep it for 180s after the alloy is completely melted. In order to obtain alloy ingots with uniform composition, all samples were sm...

Embodiment 2

[0041] Take Al with a purity of 99.9wt.% 2 o 3 Particles and Hf, Nb, Ta, Ti, Zr, V elemental pure metal particles with a purity of not less than 99.95wt.%. After the metal particles are mechanically polished to remove scale and ultrasonically cleaned and dried, the 2 o 3 Precise batching, the ratio is 15.95at.% Hf, 15.95at.% Nb, 15.95at.% Ta, 15.95at.% Ti, 15.95at.% Zr, 15.95at.% V, 4.3at.% Al 2 o 3 . The weighed raw materials are placed in the water-cooled copper mold crucible of the non-consumable vacuum arc melting furnace in the order of the melting point of the elements from low to high, and the ceramic phase is placed at the bottom. Vacuum the chamber to 5×10 before melting -3 Pa, filled with argon to 0.7 atmospheres. When smelting, first smelt the titanium ingot in the furnace for 180s to remove the residual oxygen in the furnace cavity; when smelting the target alloy, keep it for 180s after the alloy is completely melted, and no alloy ingot with uniform compositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com