Lipase-metal palladium nanoparticle composite catalyst as well as preparation method and application thereof

A composite catalyst and nanoparticle technology, applied in catalyst activation/preparation, biochemical equipment and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the mismatch of reaction conditions, environmental pollution, and synergistic use Uncommon and other problems to achieve the effect of increasing hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

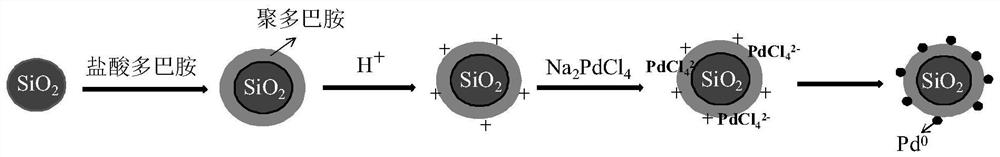

[0060] Example 1: SiO 2 Synthesis of @PDA@Pd catalysts, such as figure 1 shown

[0061] (1) SiO 2 Preparation of @PDA: Weigh 0.5g of SiO 2 In a beaker, add 50mL of Tric-HCl (pH8.5, 10mM) buffer solution, in order to make it evenly dispersed, ultrasonic for 10min, then add 0.5gDA-HCl, shake at 30°C, 2000rpm for 16h; centrifuge at 8000rpm Collect the precipitate for 5 minutes, wash and centrifuge twice with deionized water, disperse the obtained black precipitate in 100 mL of deionized water, and disperse it evenly by ultrasonication for 10 minutes, then divide it into 10 parts, and absorb 10 mL of each part into a centrifuge tube. Each portion was centrifuged to remove the supernatant for later use; one portion was freeze-dried, and its weight was 50.2 mg.

[0062] (2) SiO 2 Preparation of @PDA@Pd:

[0063] Take the SiO prepared above 2 Six parts of @PDA were ultrasonically dispersed in 10mL solutions with pHs of 8, 6, 7, 5, 4, and 3 respectively (the concentration of HC...

Embodiment 2

[0068] Example 2: mSiO 2 Preparation of @PDA@Pd@CALB composite catalyst, such as figure 2 shown

[0069] (1) mSiO 2 Preparation of @PDA@Pd: Weigh SiO prepared under the above optimal conditions 2 @PDA@Pd100mg in a 25mL round bottom flask, add 9mL of toluene, ultrasonic 10min to make it evenly dispersed, then add 1mL of octadecyltrimethoxysilane (TMODS), reflux at 90°C for 15h; centrifuge at 8000rpm Collect the precipitate for 5 min, wash and centrifuge twice with toluene, then wash and centrifuge three times with absolute ethanol, and then dry it in vacuum at 50°C to obtain mSiO 2 @PDA @Pd.

[0070] (2) mSiO 2 Preparation of @PDA@Pd@CALB composite catalyst: Weigh 50mg of mSiO 2 After @PDA@Pd was dispersed with 0.1mL of absolute ethanol, 9.4mL of phosphate (pH7.4, 100mM) buffer was added, ultrasonicated for 10min to disperse evenly, and 0.5mL of enzyme liquid (Novozymes’ CALB, nominal activity 5000LU / g), shaking at 30°C, 200rpm on a shaker for 4h; centrifuging at 8000r...

Embodiment 3

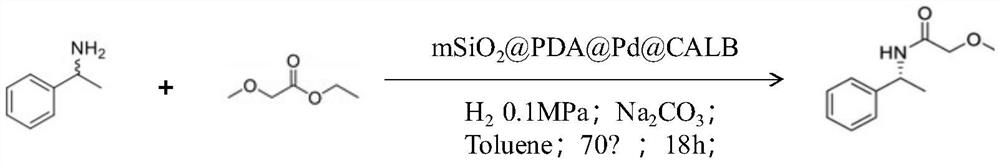

[0072] Example 3: SiO 2 Application of @PDA@Pd catalyst, prepared SiO 2 Dynamic Kinetic Resolution of α-Phenylethylamine by @PDA@Pd and Novozym 435 (Commercial Lipase)

[0073]

[0074] Weigh the SiO prepared in Example 1 2 @PDA@Pd and Novozym 435 each 30mg, 20mg Molecular sieves, 50 mg of anhydrous sodium carbonate in a Schlenk bottle, add 2 mL of toluene, 0.06 mL of the substrate α-phenethylamine, 0.1 mL of ethyl methoxyacetate; fill with H 2 -Ar mixed gas (H 2 accounted for 5%), and maintain a pressure of 0.1Mpa; catalysis at 70 ℃ for 18h. The reaction was detected by gas chromatography.

[0075] Table 1

[0076] Entry catalyst Conversion rates / % ee p / %

[0077] Table 1 is SiO prepared under different pH in embodiment 3 2 @PDA@Pd Catalyst and Novozym 435 (commercial lipase) Dynamic Kinetic Resolution Data of α-Phenylethylamine, Through the Yield and ee p Value comparison, the SiO prepared at pH 4 can be obtained 2 @PDA@Pd pH4 The catalytic e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com