A phase change furnace for preparing high-temperature alumina powder and its application method

A high-temperature alumina, phase change furnace technology, applied in chemical instruments and methods, fluidized bed furnaces, furnaces, etc., can solve problems such as insufficient residence time, achieve stable production and operation, meet long-term flow, and save land. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

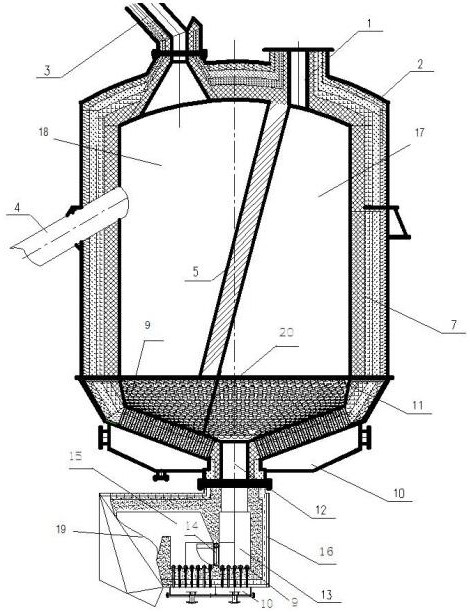

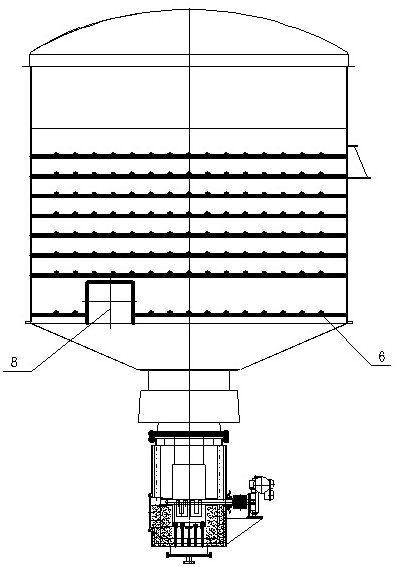

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0035] like figure 1 and figure 2As shown, a phase change furnace for preparing high-temperature alumina powder includes a feeding port 1, an outer casing 2, an air outlet 3, an overflow port 4, a wall body 5, a furnace lining 7, a wall feeding port 8, and a wind cap 9 , the air chamber 10 , the ventilation distribution plate 11 , and also includes the discharge port 12 and the flow sealing valve 16 .

[0036] The outer shell 2 is provided with an interlayer, and a furnace lining 7 is built in the inner cavity of the interlayer; a wall 5 is provided inside the phase change furnace, and a ventilation distribution plate 11 is provided at the lower end of the interior of the phase change furnace.

[0037] A plurality of air caps 9 are distributed on the bottom side of the interior of the phase change furnace in a circular arch shape, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com