Belt-pressure high-precision quantitative feeding system

A feeding system, high-precision technology, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of waste of resources, difficulty in accurately quantifying the amount of materials added, and accelerate resource consumption, so as to reduce waste. , Improve the reaction efficiency and the utilization rate of materials, and improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

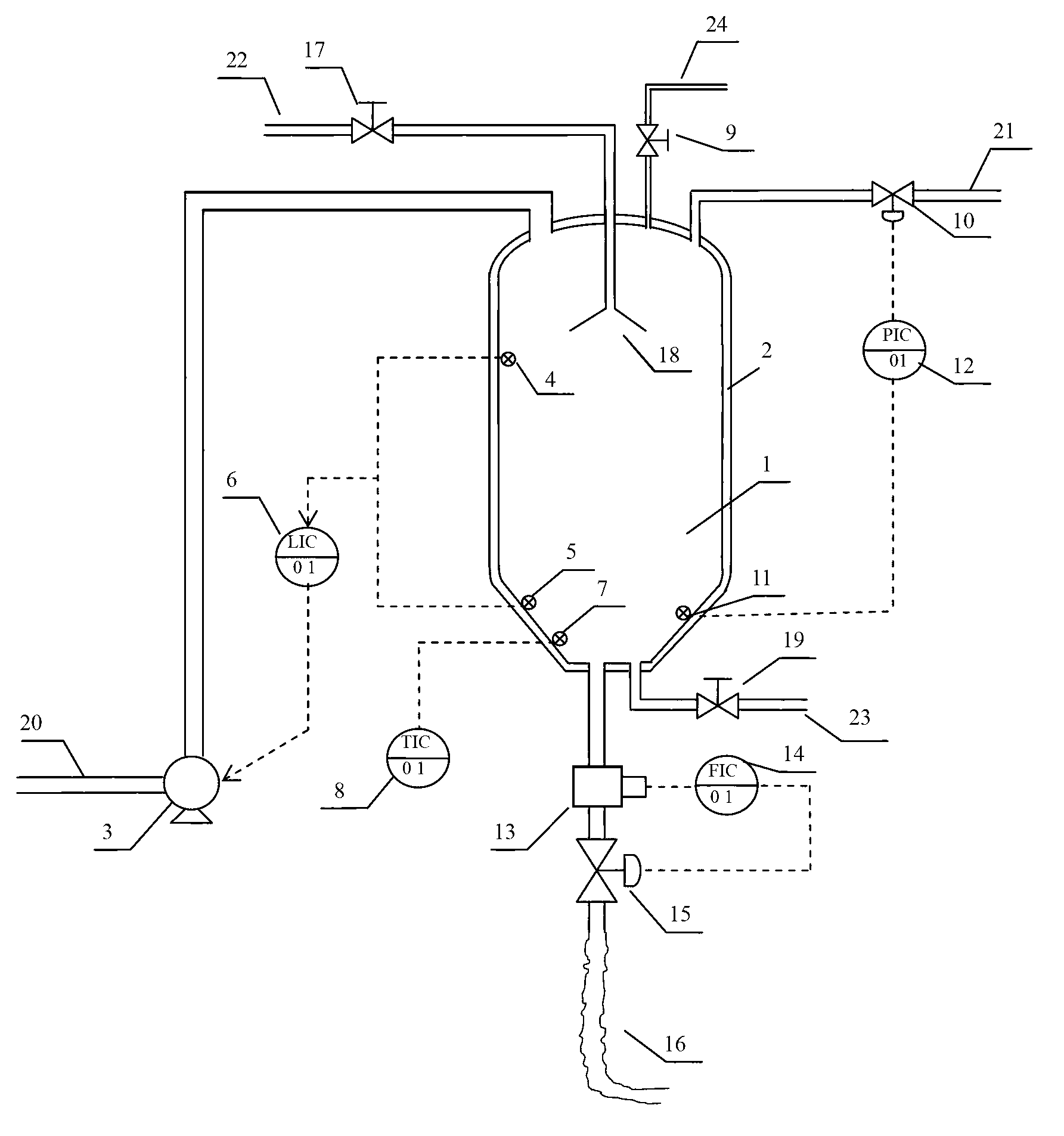

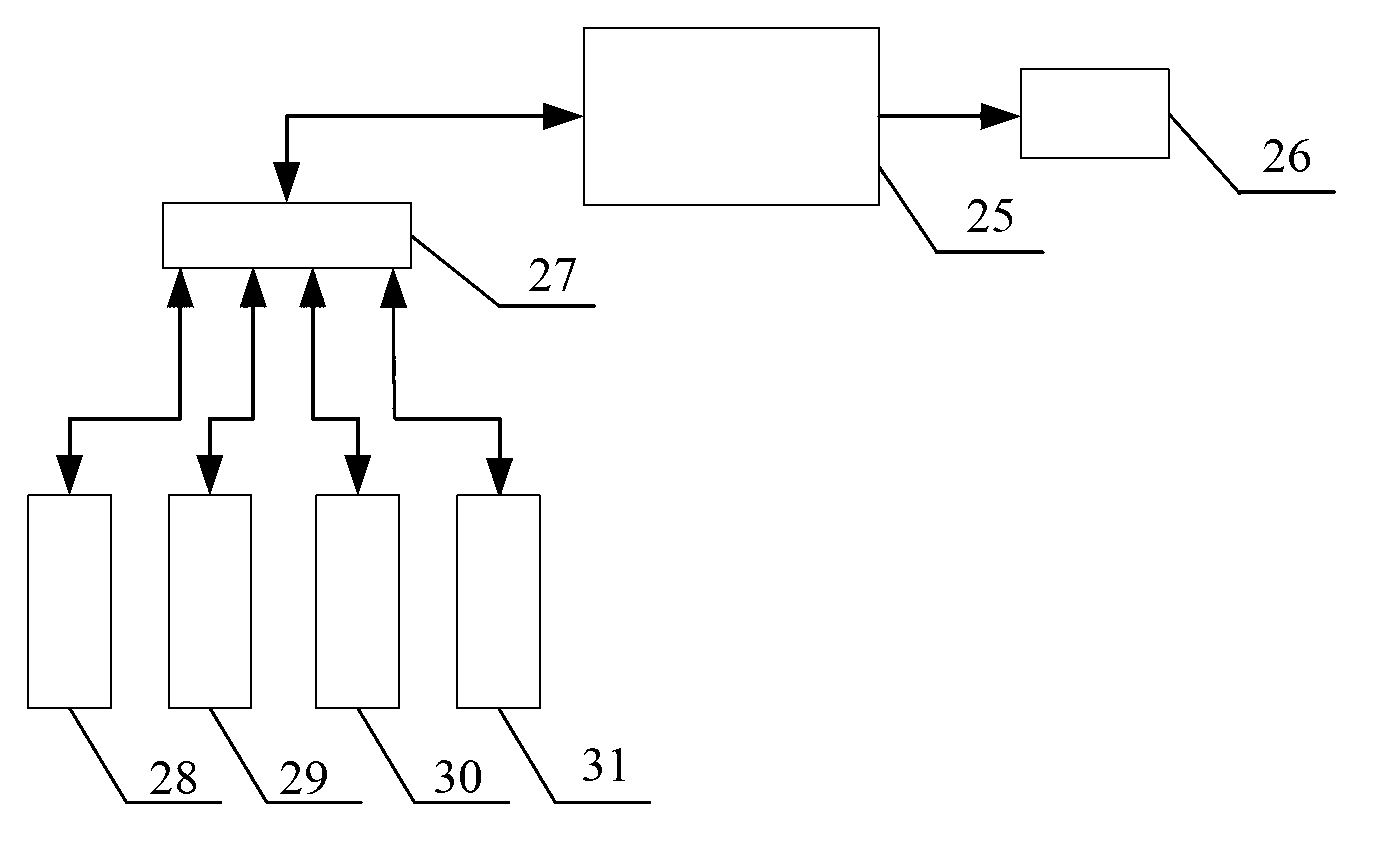

[0029] see figure 1 with figure 2 , the present invention includes a reaction tank 1, a liquid level control circuit 28 for monitoring and adjusting the liquid level height in the reaction tank 1, a pressure control circuit 29 for monitoring and adjusting the pressure in the reaction tank 1, a pressure control circuit 29 for monitoring and adjusting the reaction tank 1 flow control loop 30 for the output and a temperature display control device 31 for displaying the temperature in the reaction tank 1 and adjusting the feed temperature. The outside of the reaction tank 1 is provided with an insulating layer 2, and the bottom of the reaction tank 1 is provided with a material outlet, and the top of the reaction tank 1 is communicated with the feed pipeline 20, and the feed pipeline 20 is provided with a feed pump 3; the liquid level control lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com