Waterproof casing pipe structure of dewatering well point and construction method

A technology of waterproof casing and construction method, which is applied in the direction of infrastructure engineering and construction, which can solve the problems of failure to achieve anti-floating design, hidden dangers of large building quality and safety, and no sealing measures for well points, so as to reduce manpower and material costs, reducing the possibility of water seepage in the later stage, and ensuring the effect of well point plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

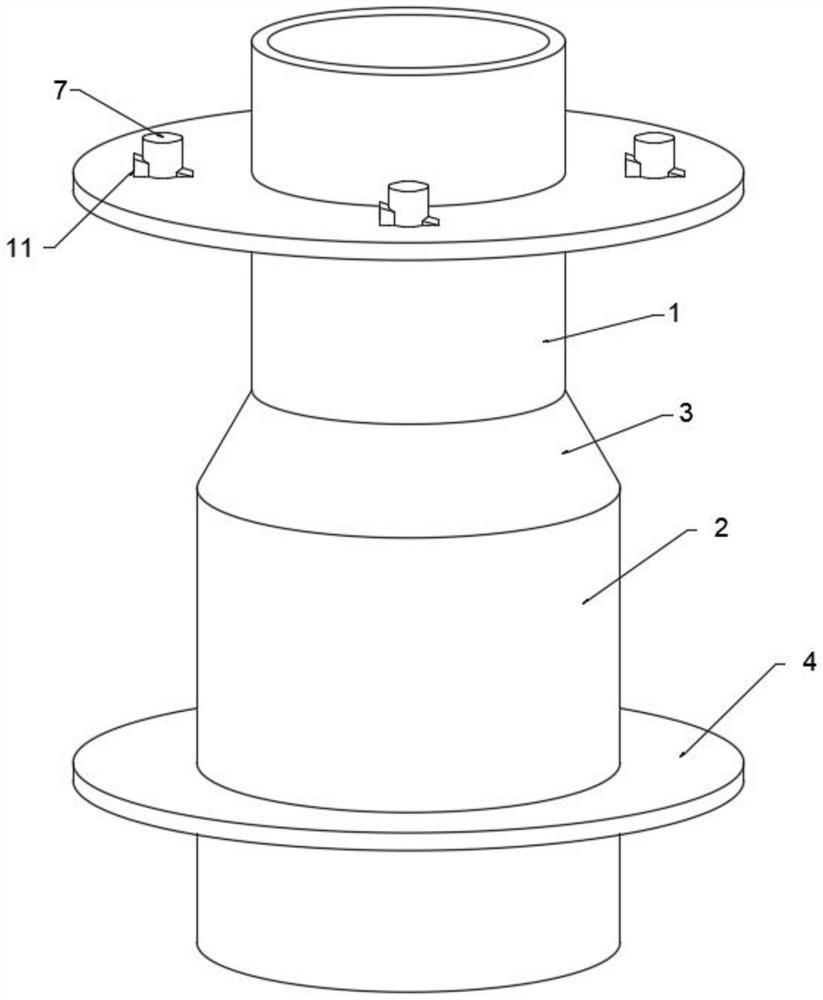

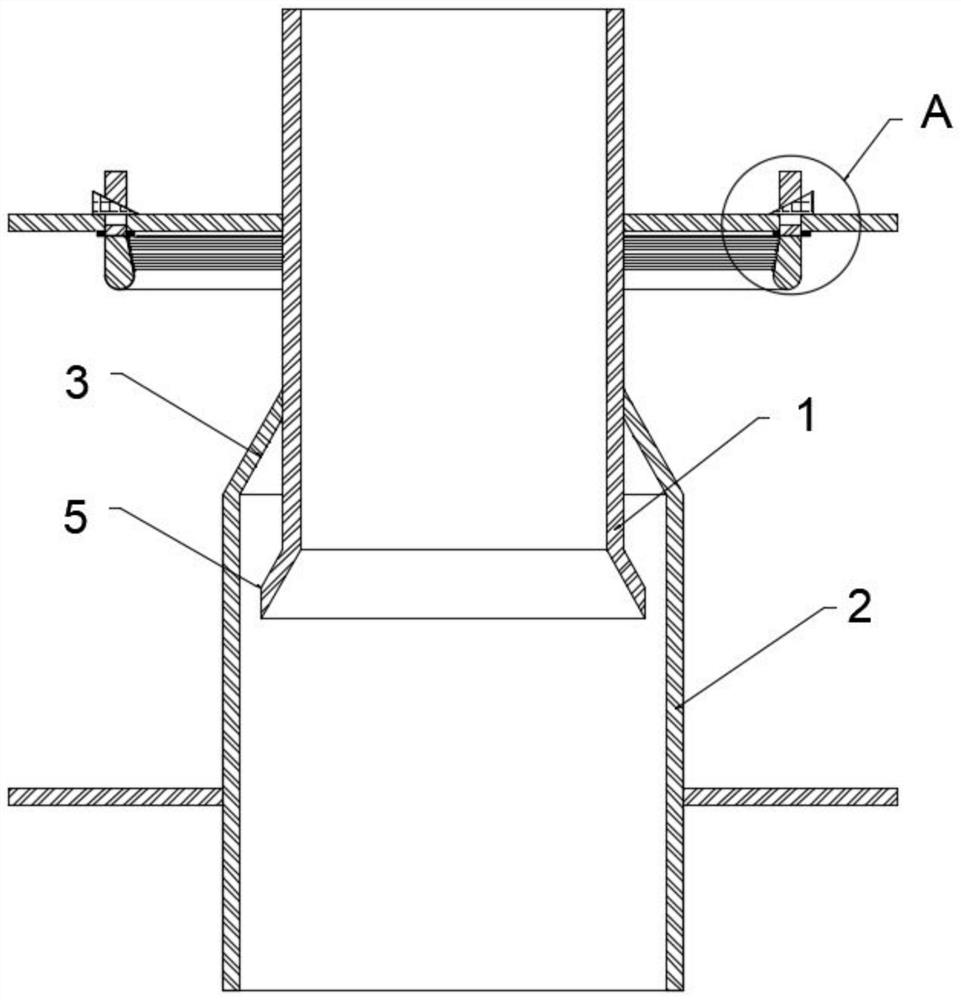

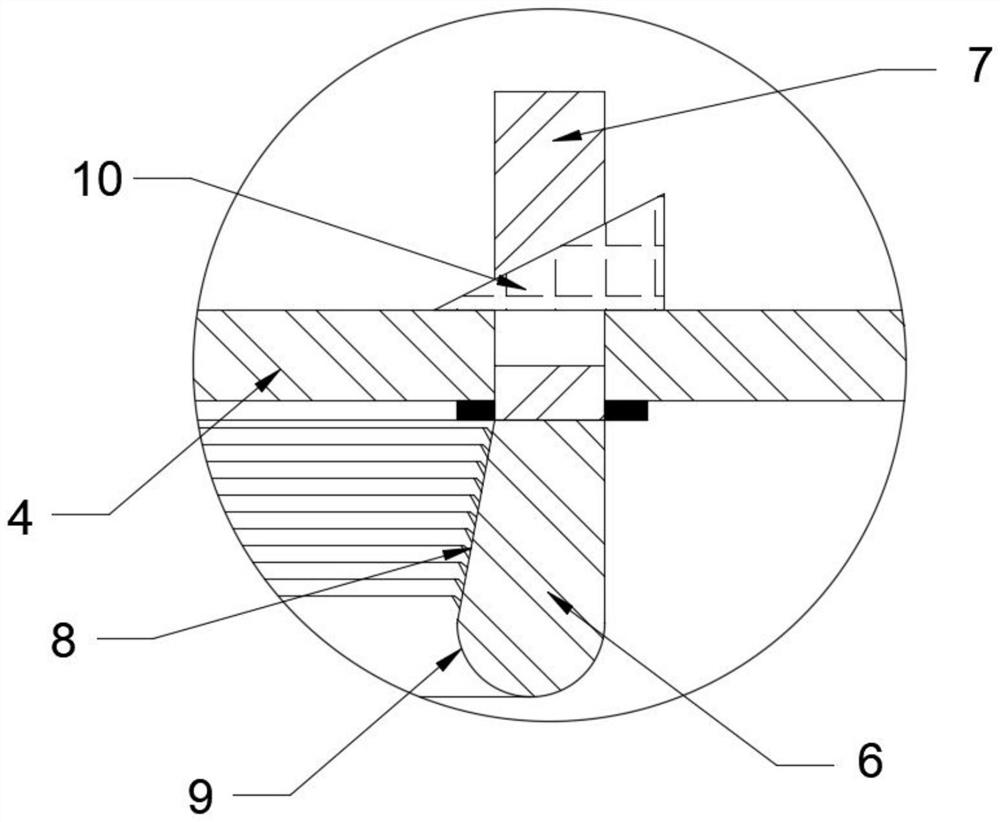

[0030] Example: such as figure 1 As shown, a waterproof casing structure for a dewatering well point, including casing one 1 and casing two 2, the top of casing two 2 is provided with a closing structure 3, casing one 1 is partly inserted into the inside of the closing and the casing One 1 and the closing structure 3 are fixedly installed, and the outer sides of casing one 1 and casing two 2 are equipped with a water-stop structure 4, and the two water-stop structures 4 include water-stop steel plates, which are used for casing-one 1 through the water-stop steel plates And the anti-leakage water effect of casing two 2 outsides, be positioned at the waterproof ring 6 that is installed on the waterproof steel plate on casing one 1, can guarantee the waterproof performance of outer top by waterproof ring 6.

[0031] Preferred scheme on the basis of above-mentioned embodiment: as Figures 1 to 3 As shown, the water-stop steel plate is provided with a guide hole, and the waterproo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com