Method for rapidly eliminating element segregation in rare earth magnesium alloy by using pulse current

A pulsed current and rare earth element technology, applied in the field of element segregation, can solve the problems of the rare earth magnesium alloy homogenization refining, complex processing process, affecting refining process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, pulse current treatment is performed on the rare earth magnesium alloy. Specific steps are as follows:

[0046] S1: Smelting a rare earth magnesium alloy with the rare earth element gadolinium (Gd) as the main alloying element. Put the dried magnesium alloy into the crucible, add RJ-2 covering agent, and raise the temperature of the crucible to 760°C through two stages of slow heating (180°C / h) and rapid heating (280°C / h) for a total of 3 hours.

[0047] S2: Determine pulse current processing parameters. The range of pulse current processing parameters is set, and the pulse current parameters are determined to be 31000Hz, 30μs, 80A, and the action time is 10min.

[0048] S3: Pulse current processing. Insert the prepared steel electrodes into both sides of the crucible symmetrically, confirm that the electrodes are inserted into the melt by 3mm; connect the pulse current generator, and perform 10min pulse current treatment.

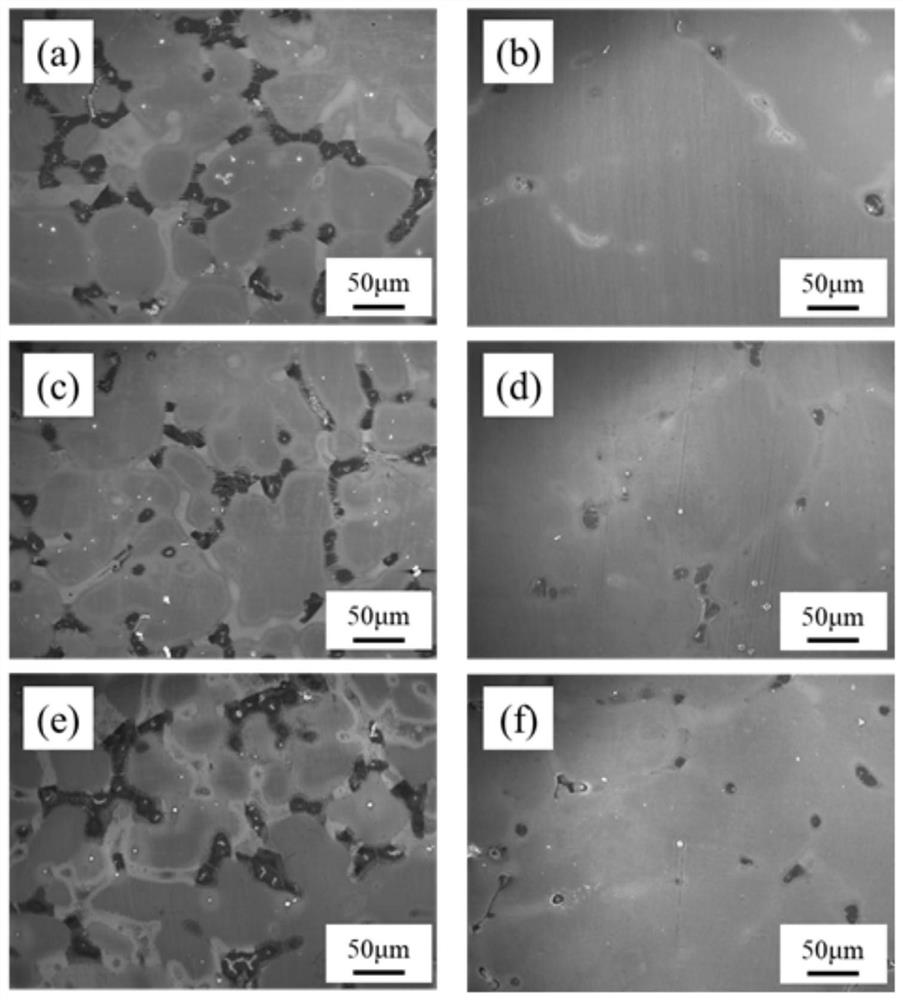

[0049] S4: Conduct SE...

Embodiment 2

[0051] In this embodiment, pulse current treatment is performed on the rare earth magnesium alloy. Specific steps are as follows:

[0052] S1: Smelting a rare earth magnesium alloy with the rare earth element gadolinium (Gd) as the main alloying element. Put the dried magnesium alloy into the crucible, add RJ-2 covering agent, and raise the temperature of the crucible to 760°C through two stages of slow heating (180°C / h) and rapid heating (280°C / h) for a total of 3 hours.

[0053] S2: Determine pulse current processing parameters. The parameter range of the pulse current is set, and the pulse current parameter is determined to be 31000Hz, 30μs, 60A, and the action time is 15min.

[0054] S3: Pulse current processing. Insert the prepared steel electrodes into both sides of the crucible symmetrically, confirm that the electrodes are inserted into the melt by 3mm; connect the pulse current generator, and perform 15min pulse current treatment.

[0055] S4: Conduct SEM scanning...

Embodiment 3

[0057] In this embodiment, pulse current treatment is performed on the rare earth magnesium alloy. Specific steps are as follows:

[0058] S1: Smelting a rare earth magnesium alloy with the rare earth element gadolinium (Gd) as the main alloying element. Put the dried magnesium alloy into the crucible, add RJ-2 covering agent, and raise the temperature of the crucible to 760°C through two stages of slow heating (180°C / h) and rapid heating (280°C / h) for a total of 3 hours.

[0059] S2: Determine pulse current processing parameters. The parameter range of the pulse current is set, and the pulse current parameter is determined to be 31000Hz, 30μs, 80A, and the action time is 5min.

[0060] S3: Pulse current processing. Insert the prepared steel electrodes into both sides of the crucible symmetrically, confirm that the electrodes are inserted into the melt by 10mm; connect the pulse current generator, and perform 5min pulse current treatment.

[0061] S4: Conduct SEM scanning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com