Device for removing foreign material from molten metal surface in steel sheet hot-dip galvanizing process

A technology of hot-dip galvanizing and molten metal, which is applied in hot-dip galvanizing process, grease/oily substance/floating matter removal device, metal material coating process, etc. It can solve the problems of reduced quality of galvanized steel plate and inability to discharge impurities, etc. , to achieve the effect of reducing the load and improving the quality of galvanizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

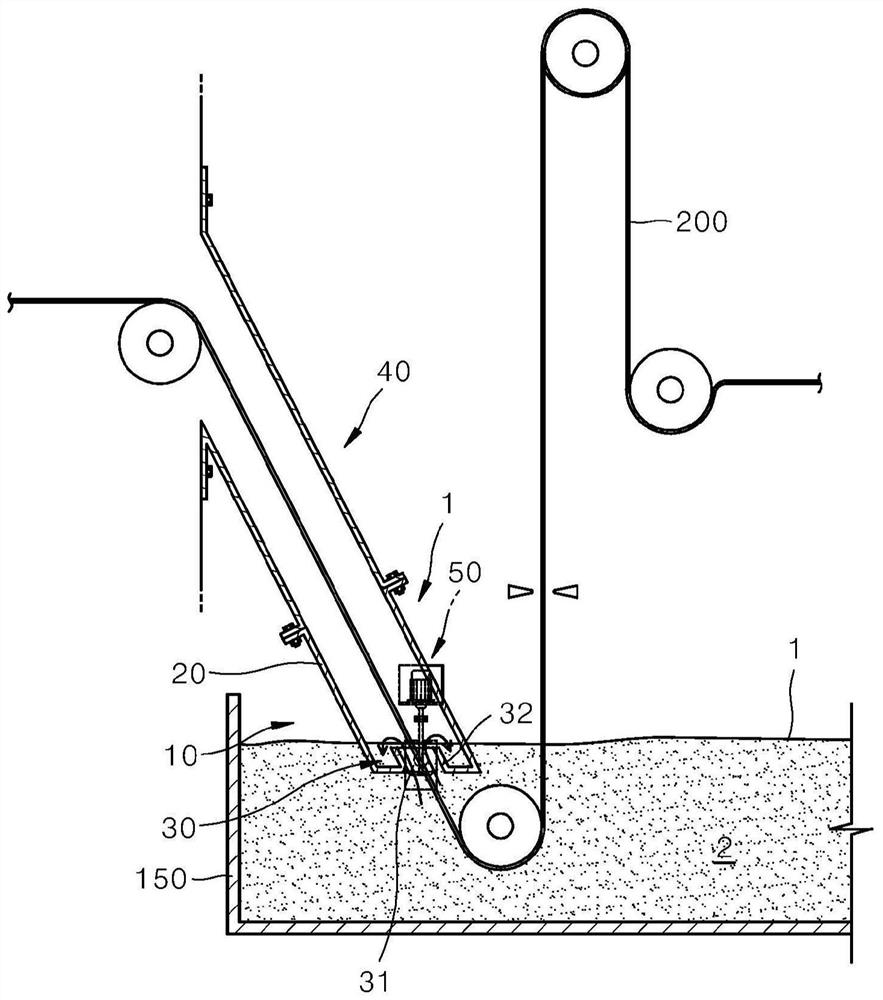

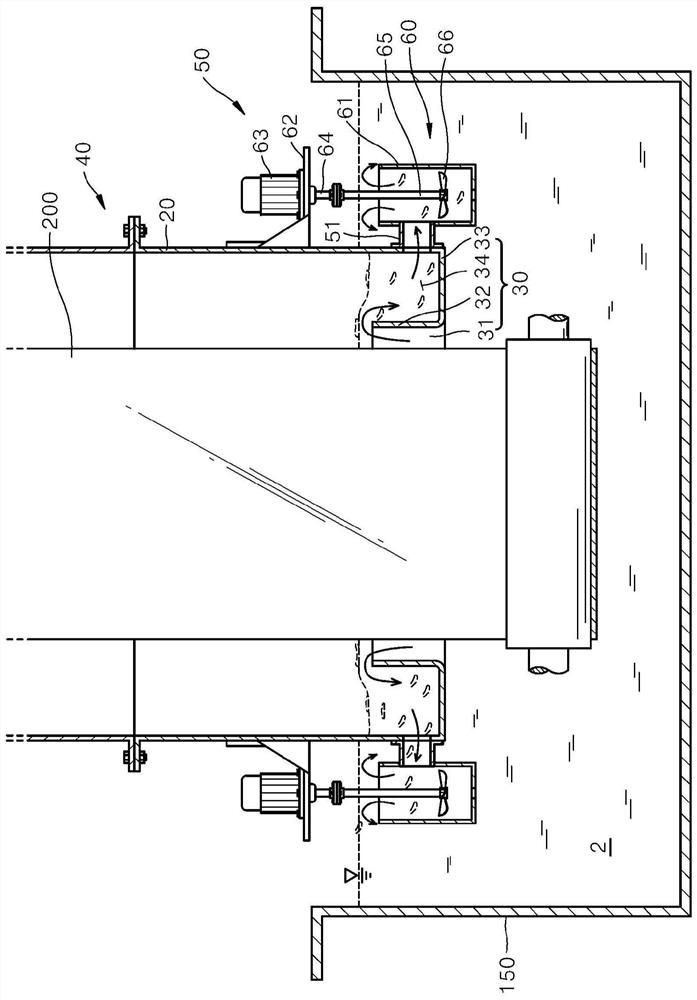

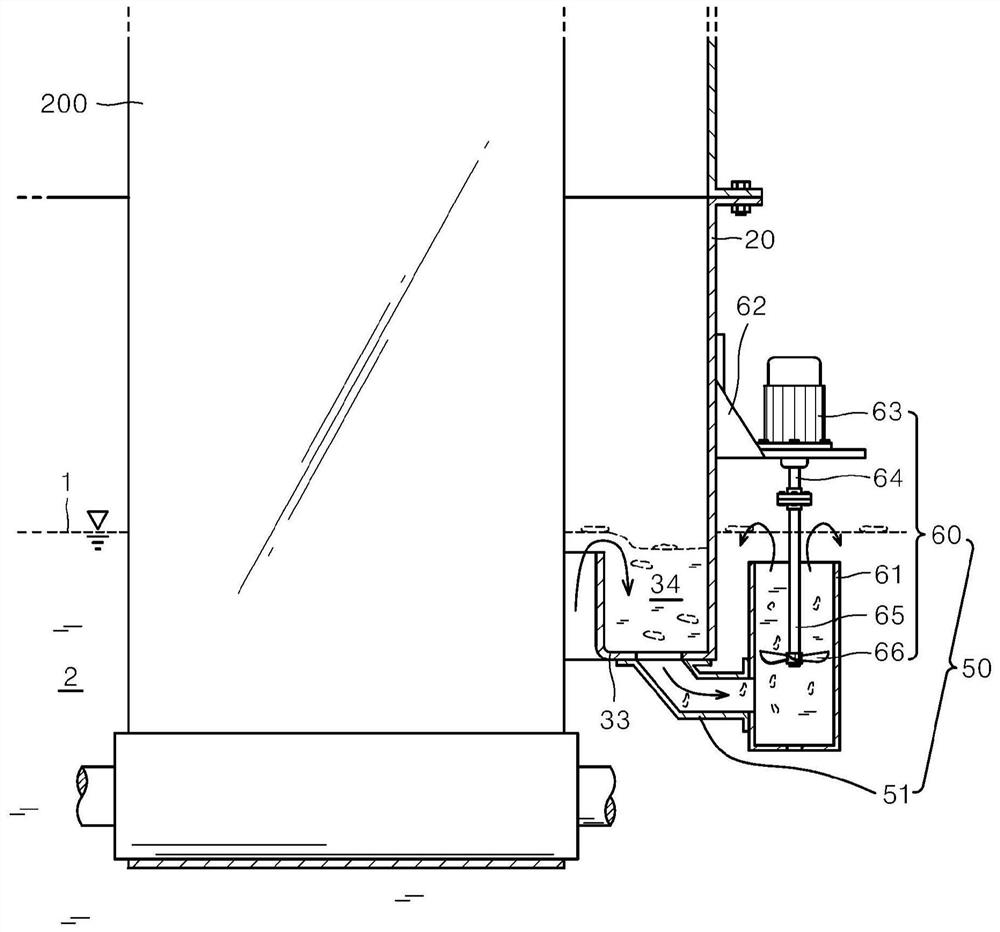

[0035] Figure 1 to Figure 5 An example of an apparatus for removing impurities from a molten metal surface in a steel sheet hot-dip galvanizing process according to the present invention is illustrated.

[0036] Referring to the accompanying drawings, an apparatus 10 for removing impurities from a molten metal surface in a steel sheet hot-dip galvanizing process according to the present invention is installed in a hot-dip galvanizing bath 150 to prevent the surface of a steel sheet 200 heat-treated at a high temperature from Oxidizes when the steel plate 200 is exposed to the atmosphere. In addition, the apparatus 10 has a structure for preventing surface defects from occurring due to ash, which is formed by condensing vapor of a hot-dip galvanizing solution and adheres to the surface of the steel sheet 200 as impurities.

[0037] The apparatus 10 for removing impurities from a molten metal surface in a steel sheet hot-dip galvanizing process has a nozzle portion 40 having a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com