Humidity self-regulated irrigator for microirrigation

A self-regulating and humidity technology, applied in watering devices, climate change adaptation, gardening, etc., can solve the problems of high cost and large engineering volume, and achieve the effect of reducing complexity and installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

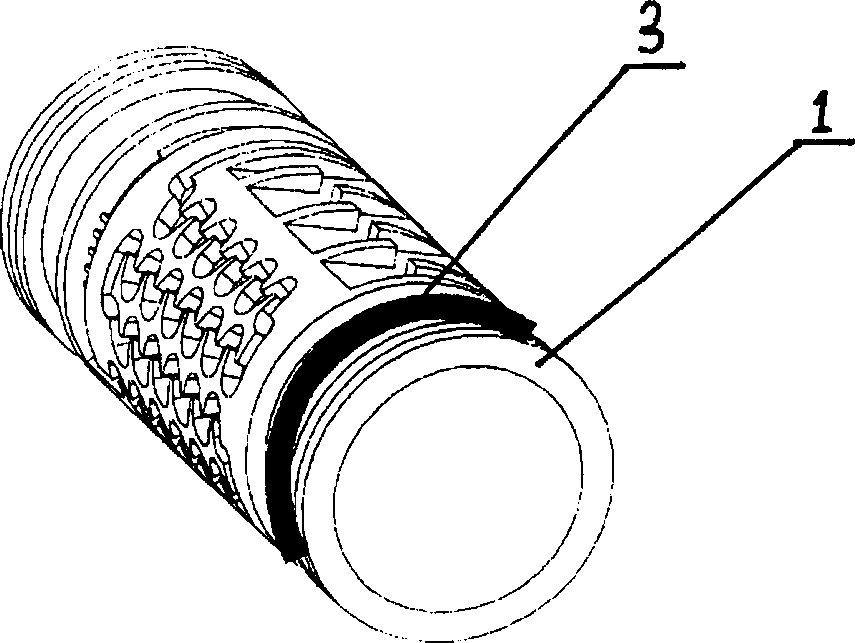

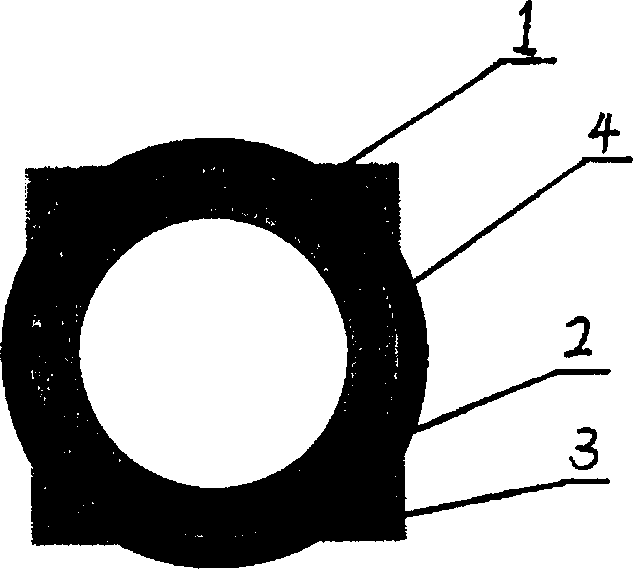

[0010] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0011] see figure 1 , 2 3. The humidity self-regulating micro-irrigation emitter of the present invention is provided with a humidity-sensitive material control ring 3 on the periphery of each water outlet area 2 of the drip irrigation belt 1, and the humidity-sensitive material control ring 3 can use electrolytes, organic matter, and metal oxidation. made of moisture-sensitive materials such as silicon or silicon single crystals. Typical electrolyte humidity sensitive materials include LiCl; organic polymer humidity sensitive materials include PVC (polyvinyl alcohol) and LiCl mixture, butyl acetate fiber, polystyrene sulfonic acid ion exchange resin (PSS), polyimide (pl ), polydiacetylene, polypropynyl alcohol doped with sulfuric acid, etc.; metal oxide-based moisture-sensitive materials include Fe 2 o 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com