Underground diaphragm wall seam water stop strengthening measure and detection method

A technology of underground diaphragm wall and detection method, which is applied in water conservancy projects, underwater structures, artificial islands, etc., can solve problems such as leakage, and achieve the effects of low implementation risk, improved quality, and prevention of potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A water-stop strengthening measure and detection method for an underground diaphragm wall joint, the method comprising the following steps:

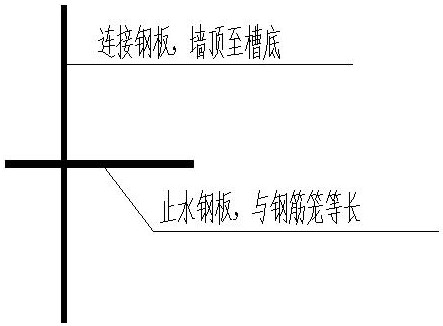

[0038] Step 1: The ground connection wall joint adopts the rigid joint of cross steel plate, and the joint is processed and prefabricated in the factory to ensure the quality of the weld seam.

[0039] Step 2: Weld the angle steel at both ends of the cross steel plate joint to place the anti-slip iron sheet. The longitudinal length of the iron sheet is equal to the wall of the ground connection wall, and the width of the iron sheet is 900mm;

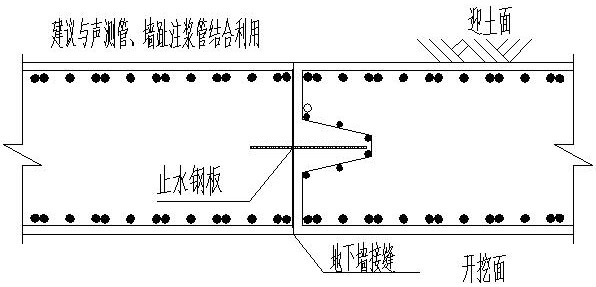

[0040] Step 3: A steel sleeve valve pipe is pre-embedded on the sealing rib of the reinforcement cage outside the cross steel plate at the joint of each ground connection wall;

[0041] Sleeve tube protection measures:

[0042] ①The segments of the sleeve valve tube are connected by sleeve wire, the thread buckle is wrapped around the raw material belt, and the bottom is closed with a welde...

Embodiment 2

[0050] According to the measures and detection methods for strengthening the waterproofing of underground continuous wall joints described in Embodiment 1, the detection method in the described step 5 includes the following steps:

[0051] (1) Whether there is a seepage channel in the overall high water pressure test;

[0052] Install a grouting valve on the top of the sleeve valve pipe, and use a high-pressure grouting pump above 6Mpa to conduct a hydraulic test on the pipe section. If there is no obvious pressure drop or flow rate, it can be confirmed that the quality of the seam seal is good. The flow rate indicates that there is a seepage channel in the joint;

[0053] (2) Determine the specific location of the seepage channel;

[0054] If there is a seepage channel in the test, further use the sleeve valve pipe matching grouter to gradually layer up from the bottom, and conduct a hydraulic test every 20cm. location, and finally find out the specific number and location ...

Embodiment 3

[0059] According to the measures and detection methods for strengthening the waterproofing of underground continuous wall joints described in Embodiment 1 or 2, the specific steps of the third step are as follows:

[0060] The sleeve valve tube is made of Φ48*2.8mm seamless steel pipe (the surface of the steel pipe needs to be derusted), and a grouting valve is set at a longitudinal interval of 200mm. Each grouting valve includes 4 Φ6 grouting holes in the circumferential direction, and the jacket is 80mm wide. The two ends of the valve (a bicycle inner tube is enough) and the leather valve are fixed by tape wrapping. Each section of the sleeve valve tube is 6m long, and the sections are connected by sleeves;

[0061] The sleeve valve tube is bound and fixed inside the inflection point of the groove of the sealing rib during the steel cage processing stage. The embedment range of the sleeve valve pipe is from the surface to the depth of 6m below the bottom of the foundation pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com