Quick repairing device for roads

A fast and high-speed technology, applied in the direction of road repair, road, road, etc., can solve the problems of poor quality of pavement seams, etc., and achieve the effect of improving construction quality, energy-saving structure, and improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

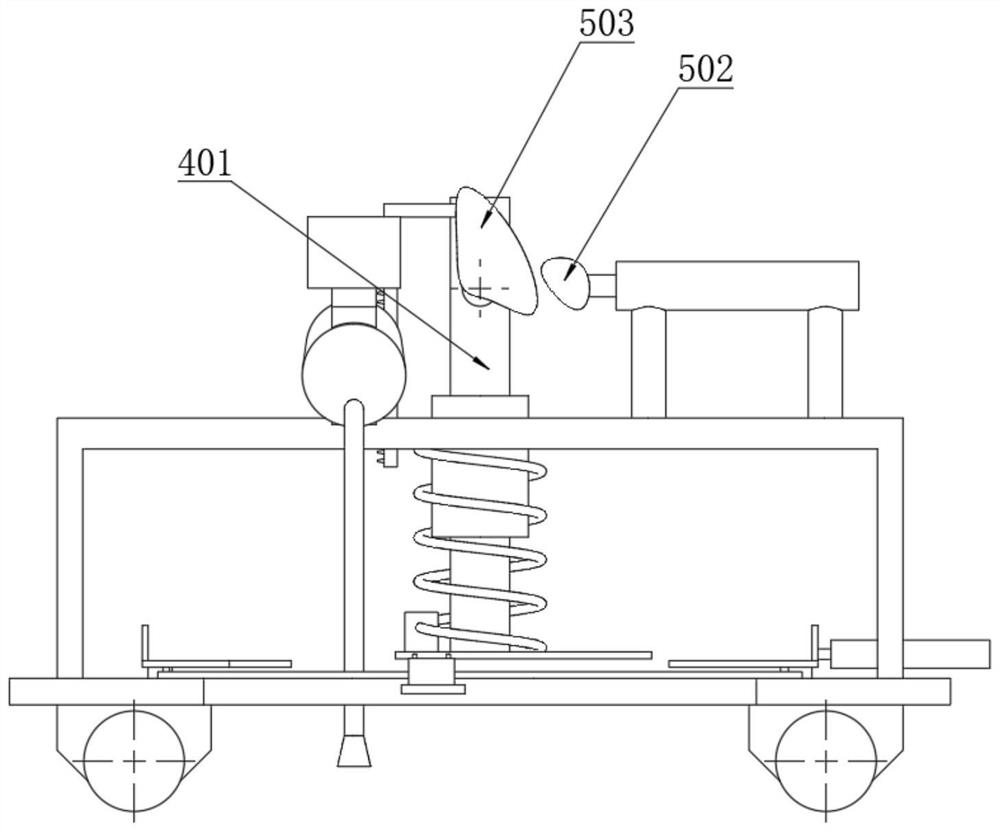

[0036] Refer to attached Figure 1-12 , a road quick repair device, comprising a moving base 1, a scraper mechanism 7 and a link mechanism 9, a U-shaped beam 2 is installed on the top surface of the moving base 1, and a mixing mechanism 3 and a top are installed on the top of the U-shaped beam 2 Pressing mechanism 5, the middle part of U-shaped beam 2 is provided with beating mechanism 4, and pressing mechanism 5 drives beating mechanism 4 to press down, and when beating mechanism 4 is pressed down, the asphalt filled in linkage mixing mechanism 3 is mixed and stirred backward. The bottom discharge, the mixing mechanism 3 is two groups of front and rear, and the two groups of mixing mechanisms 3 are also equipped with a discharge mechanism 6 to discharge the asphalt material downwards, and the scraper mechanism 7 is two places, which are respectively installed on the U-shaped beam 2 The left and right sides of the left and right sides of the connecting rod mechanism 9 are two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com