Preparation method of alloy-like ASA plastic

An alloy and plastic technology, which is applied in the field of preparation of alloy-like ASA plastics, can solve the problems of low segment cutting efficiency, manual bagging, and increase the work intensity of operators, so as to improve the degree of automation, improve impact resistance, and improve segment performance. The effect of cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] like Figure 16 As shown, a preparation method of an alloy-like ASA plastic comprises the following steps:

[0046] Step 1: 74% polycarbonate, 20% ASA, 3% compatibilizer, 3% toughener, and 0.1% primary antioxidant agent, auxiliary antioxidant with mass fraction of 0.2%, lubricant with mass fraction of 0.4%, mixed by high-speed mixer;

[0047] Step 2 The mixture in step 1 is melted and extruded into a columnar structure through a twin-screw extrusion device;

[0048] Step 3 Cool the columnar material obtained in Step 2 by means of water cooling;

[0049] Step 4 The columnar material obtained in step 3 is cooled again by means of air cooling;

[0050] Step 5 The air-cooled cylindrical material is conveyed to the segment cutting mechanism (11) through the feeding mechanism (12). rod-like structure;

[0051] Step 6 The cut short rod-shaped material is conveyed to the discharging member (20) under the drive of the conveying mechanism (22), and during the conveying, the ...

Embodiment 2

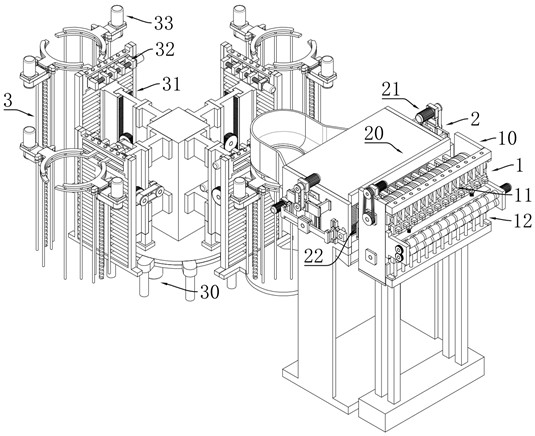

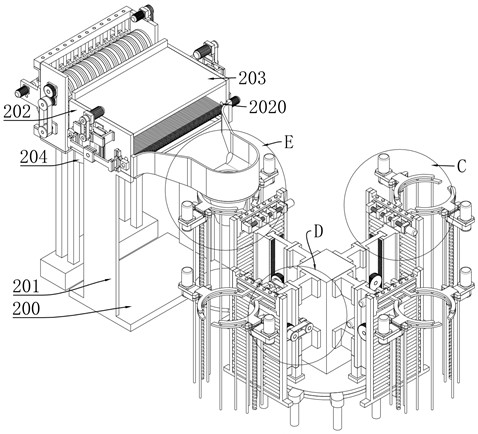

[0059] like Figure 1-Figure 15 As shown, it is a segment cutting and bagging device, which includes a segment cutting assembly 1 , a screening assembly 2 and a bagging assembly 3 . The screening assembly 2 is arranged at the discharge end of the segment cutting assembly 1 . The bagging assembly 3 is arranged at the discharge end of the screening assembly 2 . Segment cutting component 1 is used for segment cutting and conveying of extruded alloy-like ASA plastics, screening component 2 is used for screening of alloy-like ASA plastics after segment cutting and conveying and discharging of alloy-like ASA plastics, bagging component 3 It is used for the internal support of packaging bags and the bagging operation of alloy-like ASA plastics.

[0060] The segment cutting assembly 1 specifically includes a driving mechanism 10 , the upper end of the driving mechanism 10 is provided with a segment cutting mechanism 11 , the feeding end of the segment cutting mechanism 11 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com