Refrigerator door inner container punching die positioning structure

A punching die and positioning structure technology, which is applied in the field of punching die positioning structure for refrigerator door liners, can solve problems such as plate breakage, difficulty in leaving the mold, and loss of manufacturers, and achieve rapid positioning, avoid breakage, and reduce pulling stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

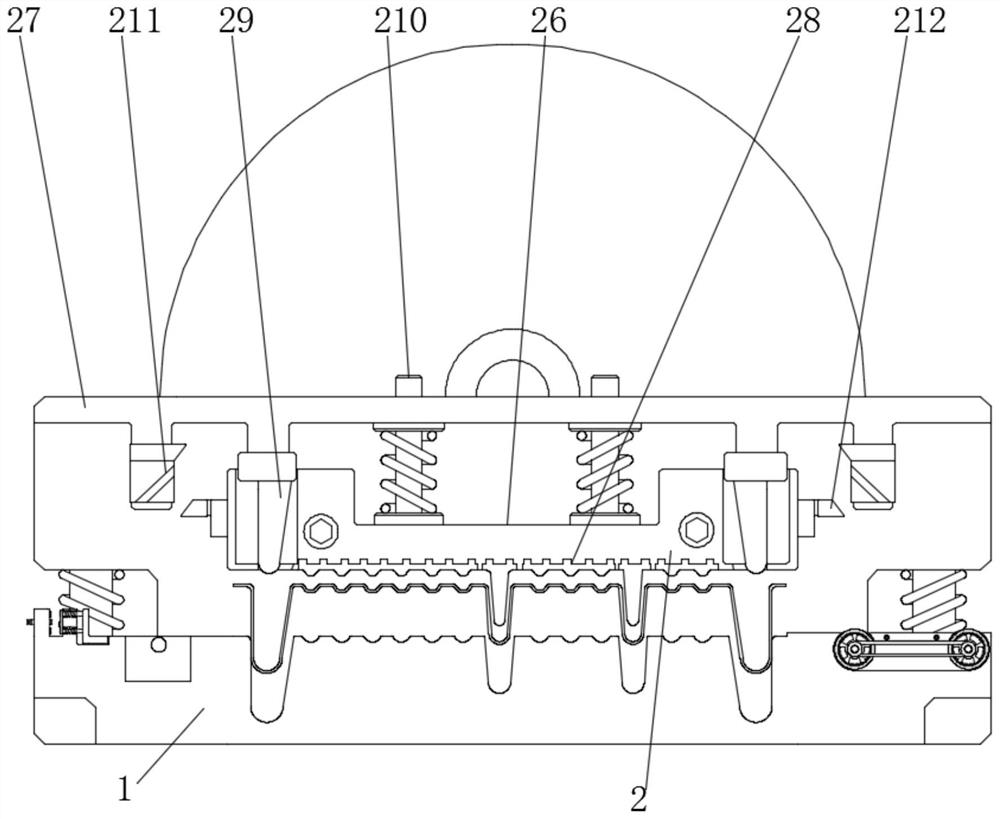

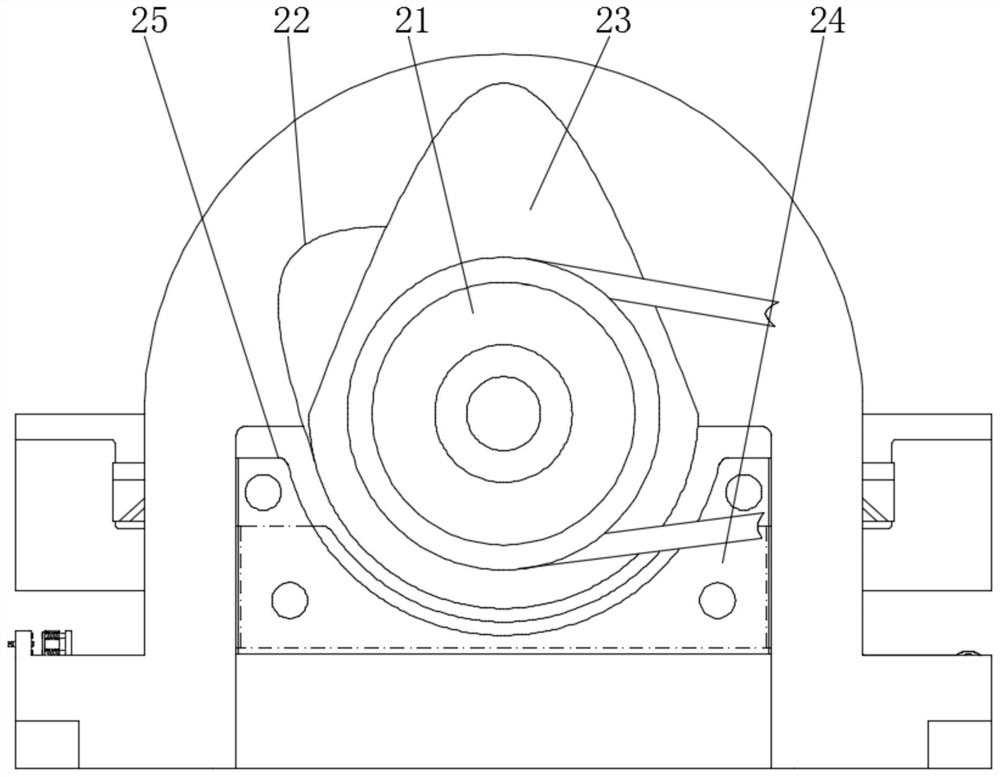

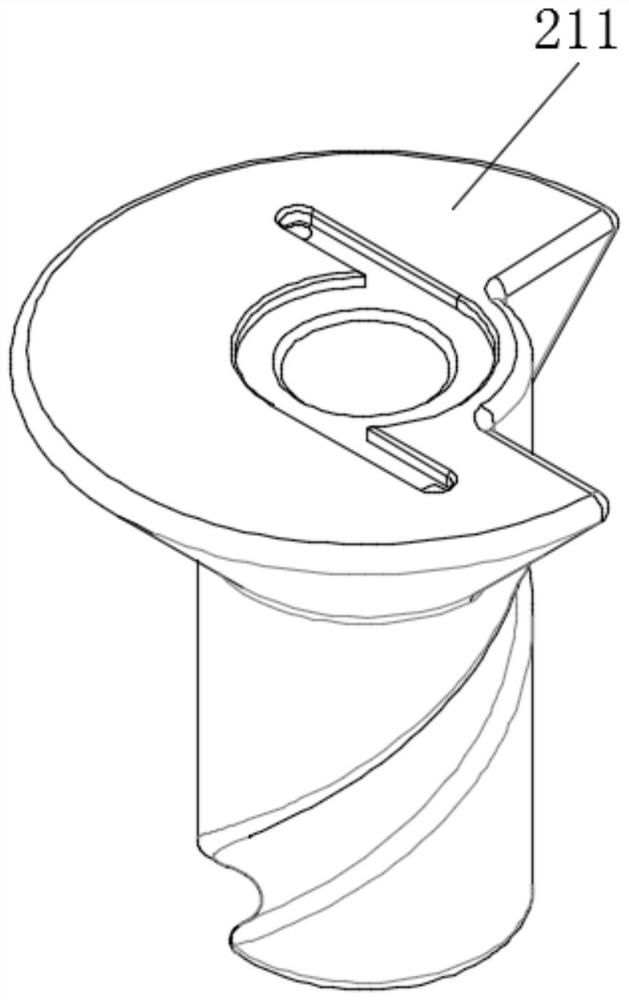

[0024] see Figure 1-3 , a punching die positioning structure for refrigerator door liner, also includes a stamping forming mechanism 2, the stamping forming mechanism 2 includes a stamping pulley 21, the stamping pulley 21 is connected to a motor through a belt, and the stamping pulley 21 is connected to a primary cam through a rotating shaft 22 and the secondary cam 23 are connected, the primary cam 22 and the secondary cam 23 become 120 degrees, the primary cam 22 is shorter than the elongation of the secondary cam 23, and the primary cam 22 can drive the primary slide plate 24 to lift, The secondary cam 23 can drive the secondary slide 25 to go up and down, and the two sets of cams can drive the two sets of slides to descend in turn, so as to achieve the effect of secondary stamping and prevent the raw material from breaking. The back of the stamping pulley 21 is connected with the secondary cam 23. The back of the secondary cam 23 is provided with a primary cam 22, the bo...

Embodiment 2

[0028] see Figure 4-6, a positioning structure for punching molds for refrigerator door liners, including a feed positioning mechanism 1, the feed positioning mechanism 1 includes a base 11, the top of the base 11 is provided with a lifting guide post 12, and the outside of the lifting guide post 12 is sleeved with a reset The spring 13, the inner rotation of the base 11 is connected with the feed wheel 14, the top of the feed wheel 14 protrudes a part than the base 11, the back of the feed wheel 14 is connected with the motor, the feed wheel 14 is connected through the transmission of the synchronous belt 15, and the synchronous belt 15 can drive the feed wheel 14 to rotate synchronously, the feed wheel 14 drives the plate 112 to feed and input, the double conveyor belt drives the plate 112 to carry out stable and automatic feeding, and the feed wheel 14 is rotated and connected with a synchronous belt 15, and the base 11 There is a mold seat 16 inside, and the inside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com